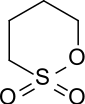

1,4-Butane sultone

1,4-butane sultone is a six-membered δ-sultone and the cyclic ester of 4-hydroxybutanesulfonic acid. As a sulfo-alkylating agent, 1,4-butanesultone is used to introduce the sulfobutyl group (–(CH2)4–SO3−) into hydrophobic compounds possessing nucleophilic functional groups, for example hydroxy groups (as in the case of β-cyclodextrin[1]) or amino groups (as in the case of polymethine dyes[2]). In such, the sulfobutyl group is present as neutral sodium salt and considerably increases the water solubility of the derivatives.

| |

| Names | |

|---|---|

| Preferred IUPAC name

1,2λ6-Oxathiane-2,2-dione | |

| Other names

δ-Butane sultone, δ-Valerosultone, Oxathiane 2,2-dioxide | |

| Identifiers | |

3D model (JSmol) |

|

| 5-19-01-00010 | |

| ChEMBL | |

| ChemSpider | |

| ECHA InfoCard | 100.015.135 |

| EC Number |

|

PubChem CID |

|

| UNII | |

CompTox Dashboard (EPA) |

|

| |

| |

| Properties | |

| C4H8O3S | |

| Molar mass | 136.17 g·mol−1 |

| Hazards | |

| GHS labelling: | |

| |

| Warning | |

| H302, H315, H319, H335, H341, H351, H412 | |

| P201, P202, P261, P264, P270, P271, P273, P280, P281, P301+P312, P302+P352, P304+P340, P305+P351+P338, P308+P313, P312, P321, P330, P332+P313, P337+P313, P362, P403+P233, P405, P501 | |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

Infobox references | |

Preparation

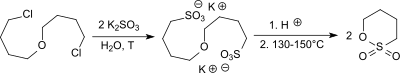

A lab scale synthesis of 1,4-butanesultone starts from 4,4'-dichlorodibutyl ether (accessible from tetrahydrofuran treated with phosphorus oxychloride and concentrated sulfuric acid),[3][4] which reacts with sodium sulfite forming the corresponding 4,4'-butanedisulfonic disodium salt. By passing it through an acidic ion exchanger, the disodium salt is converted into the disulphonic acid which forms two molecules of 1,4-butanesultone at elevated temperature and reduced pressure under elimination of water. The yields obtained range from 72 to 80%.[5]

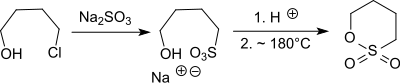

Starting from 4-chlorobutan-1-ol[6] (from tetrahydrofuran and hydrogen chloride in 54 to 57% yield), the sodium salt of 4-hydroxybutan-1-sulfonic acid is obtained with sodium sulfite. This salt is converted with strong acids (such as hydrochloric acid) into the very hygroscopic 4-hydroxybutanesulfonic acid and cyclized to 1,4-butanesultone under elimination of water.

The cyclization of 4-hydroxybutanesulfonic acid in aqueous solution proceeds particularly efficiently when heated with high-boiling, water-immiscible solvents (for example 1,2-dichlorobenzene or diethylbenzene, both boiling at about 180 °C) in which 1,4-butane-sultone dissolves and is thereby protected from hydrolysis in the aqueous medium. 1,4-butanesultone is obtained in yields of up to 99% upon reflux within one hour.[7]

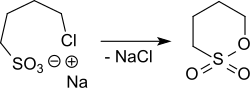

The vacuum distillation of the sodium salt of 4-hydroxybutanesulfonic acid leads in the presence of concentrated sulfuric acid directly to 1,4-butanesultone.[8] The sodium salt of 4-chlorobutane-1-sulfonic acid, which is obtained from 1,4-dichlorobutane with sodium sulfite, can also be cyclized to 1,4-butanesultone by heating to 180-250 °C.[9]

The free-radical initiated sulfochlorination of 1-chlorobutane leads to a mixture of positionally isomeric sulfochlorides and chlorination products and is therefore not suitable for the direct preparation of 1,4-butanesultone.[10]

Properties

1,4-butanesultone is a viscous, clear, colorless and odorless liquid which reacts in boiling water (to 4-hydroxybutanesulfonic acid) and alcohols (to 4-alkoxybutanesulfonic acid) and dissolves in many organic solvents. At temperatures below the melting point, the compound crystallizes giving "large, magnificent plates".[11] [3] Compared to the homologous γ-sultone 1,3-propanesultone, 1,4-butanesultone is significantly less reactive as alkylating agent, but classified as mutagenic and carcinogenic.[12]

Applications

Sulfobetaines

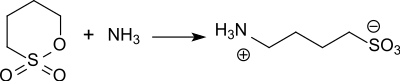

1,4-butanesultone reacts smoothly with nucleophiles such as ammonia to form the corresponding zwitterionic, usually very water-soluble sulfobutylbetaines.[11]

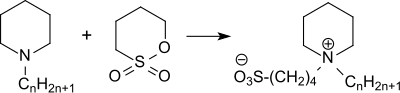

Sulfobetaines with longer alkyl chains (CnH2n+1 mit n > 10) show interesting properties as surface-active compounds (surfactants, detergents) with antimicrobial properties.[13]

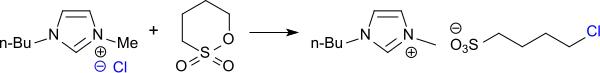

In the reaction of N-N-butylimidazole with 1,4-Butansultone in Toluene in a 98% yield is formed 1-butylimidazolium-3-(n-butylsulfonate)[14]

1-Butylimidazolium-3-(n-butylsulfonate) catalyses as a component of multifunctional catalysts the reaction of platform chemicals from biomass (for example levulinic acid or itaconic acid) into the corresponding lactones, diols or cyclic ethers.

Aminoalkylphosphonic acids (such as aminomethane diphosphonic acid, accessible from phosphorus trichloride, formamide and phosphonic acid[15]) form with 1,4-butanesultone N-(sulfobutyl)aminomethane diphosphonic acids:

aminomethandiphosphons%C3%A4ure.svg.png.webp)

N-(sulfobutyl)aminomethane diphosphonic acid is characterized by very high water solubility (< 1000 g·l−1) and a strong capability as complexing agent and water softener.[16]

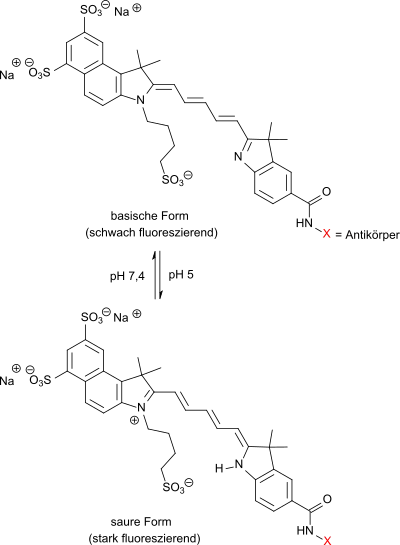

Sulfobutylation of cyanine dyes leads to readily water-soluble compounds which react with proteins like antibodies and can be used as pH-sensitive fluorescence markers.[2]

Ionic liquids

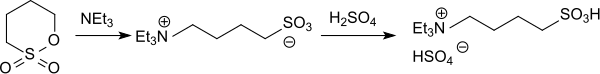

The ionic liquid 4-triethylammonium butane-1-sulfonic acid hydrogensulfate (TEBSA HSO4) is formed by the reaction of 1,4-butanesultone with triethylamine in acetonitrile to the zwitterion (85% yield) and subsequent reaction with concentrated sulfuric acid.[17]

4-triethylammonium butane-1-sulfonic acid hydrogensulfate can replace conventional mineral acids as effective and easily recyclable acid catalyst in solvent-free reactions.

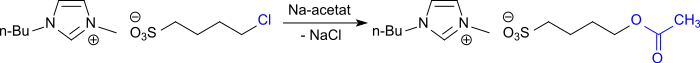

The ring opening of 1,4-butanesultone with organic chloride salts yields ionic liquids of the 4-chlorobutylsulfonate type in quantitative yield.[18]

.svg.png.webp)

The chlorine atom in the 4-chlorobutylsulfonate anion can be substituted by heating with inorganic (e.g. potassium fluoride) or organic salts (e.g. sodium acetate) by the respective anion.[19]

Sulfobutylated β-cyclodextrin

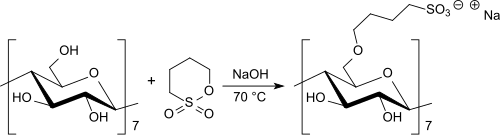

Already in 1949 the reaction of 1,4-butanesultone with the water-insoluble polysaccharide cellulose in sodium hydroxide solution was reported, which leads to a water-soluble product.[20] Derived from this the derivatization of β-cyclodextrin to sulfobutyl ether-beta-cyclodextrin (SBECD) is by now an important application of 1,4-butanesultone.[21] Sulfobutyl ether-beta-cyclodextrin is a water-soluble inclusion compound for the solubilization and stabilization of sparsely water-soluble and chemically instable components.[1][22][23] β-Cyclodextrin can be reacted with 1,4-butanesultone in sodium hydroxide solution at 70 °C to the sulfobutyl ether in yields of up to 80% and a degree of substitution of 6.68.[24]

Thereby, the water solubility of the β-cyclodextrin increases from 18.5 g · l-1 to more than 900 g · l-1 at 25 °C.[23] Sulfobutyl ether-beta-cyclodextrin also finds a wide range of applications as an inert vehicle for drug delivery (the drugs transport and release).[25]

See also

References

- H. Ueda; D. Ou; T. Endo; H. Nagase; K. Tomono; T. Nagai (1998), "Evaluation of a sulfobutyl ether beta-cyclodextrin as a solubilizing/stabilizing agent for several drugs", Drug Dev. Ind. Pharm., vol. 24, no. 9, pp. 863–867, doi:10.3109/03639049809088532, PMID 9876538

- V. Wycisk; et al. (2016), "Responsive Contrast Agents: Synthesis and Characterization of a Tunable Series of pH-Sensitive Near-Infrared Pentamethines", ACS Omega, vol. 1, no. 5, pp. 808–817, doi:10.1021/acsomega.6b00182, PMC 6044694, PMID 30023492

- "4,4'-Dichlorbutyl ether". Organic Syntheses. doi:10.15227/orgsyn.030.0027.

- K. Alexander, L.E. Schniepp (1948), "4,4'-Dichlorodibutylether and its derivatives from tetrahydrofuran", J. Am. Chem. Soc., vol. 70, no. 5, pp. 1839–1842, doi:10.1021/ja01185a056, PMID 18861793

- "4-Hydroxy-1-butanesulfonic acid sultone [1-Butanesulfonic acid, 4-hydroxy-, δ-sultone]". Organic Syntheses. doi:10.15227/orgsyn.037.0055.

- "Tetramethylene chlorohydrin". Organic Syntheses. doi:10.15227/orgsyn.017.0084.

- EP 0222970, W. Hünicke, R. Gauglitz, "Sulfoalkylierungsverfahren", published 1987-05-27, assigned to Agfa-Gevaert AG

- US 3146242, K.-J. Gardenier, H. Kothe, "Process for the preparation of sultones", published 1964-08-25, assigned to Henkel & Cie GmbH

- US 3117133, H. Kothe, K.-J. Gardenier, "Process for the production of sultones", published 1964-01-07, assigned to Henkel & Cie GmbH

- J.H. Helberger; G. Manecke; H.M. Fischer (1949), "Zur Kenntnis organischer Sulfonsäuren. II. Mitt.: Die Sulfochlorierung des 1-Chlorbutans und anderer Halogenalkyle: Synthese von Sultonen und eines Sultams", Liebigs Ann. Chem. (in German), vol. 562, no. 1, pp. 23–35, doi:10.1002/jlac.19495620104

- J.H. Helberger, H. Lantermann (1954), "Zur Kenntnis organischer Sulfonsäuren V. Mitteilung Synthesen des 1,4-Butansultons", Liebigs Ann. Chem. (in German), vol. 586, no. 1, pp. 158–164, doi:10.1002/jlac.19545860110

- L. Fishbein (1979), Potential Industrial Carcinogens and Mutagens, 1st Edition, in Studies in Environmental Science 4, Amsterdam: Elsevier, p. 124, ISBN 0-444-41777-X

- D. Wieczorek; A. Dobrowolski; K. Staszak; D. Kwasniewska; P. Dubyk (2017), "Synthesis, surface and antimicrobial activity of piperidine-based sulfobetaines", J. Surfactants Deterg., vol. 20, no. 1, pp. 151–158, doi:10.1007/s11743-016-1906-8, PMC 5222909, PMID 28111518

- F.M.A. Geilen; et al. (2010), "Selective and Flexible Transformation of Biomass-Derived Platform Chemicals by a Multifunctional Catalytic System", Angew. Chem., vol. 49, no. 32, pp. 5510–5514, doi:10.1002/anie.201002060, PMID 20586088

- US 3870750, K. Wollmann, W. Plöger, K.-H. Wopms, "Process for the production of aminomethane-diphosphonic acid and its salts", published 1975-03-11, assigned to Henkel & Cie GmbH

- US 4250107, K. Sommer, G. Schoebel, "N-(Sulfoalkane) amino alkane phosphonic acids and their water-soluble salts", published 1981-02-10, assigned to Benckiser-Knapsack GmbH

- A.R. Hajipour; Y. Ghayeb; N. Sheikhan; A.E. Ruoho (2009), "Brønsted acidic ionic liquid as an efficient and reusable catalyst for one-pot synthesis of 1-amidoalkyl 2-naphthols under solvent-free conditions", Tetrahedron Lett., vol. 50, no. 40, pp. 5649–5651, doi:10.1016/j.tetlet.2009.07.116

- N. Paape; W. Wie; A. Bösmann; C. Kolbeck; F. Maier; H.-P. Steinrück; P. Wasserscheid; P.S. Schulz (2008), "Chloroalkylsulfonate ionic liquids by ring opening of sultones with organic chloride salts", Chem. Commun., no. 33, pp. 3867–3869, doi:10.1039/B805444D, PMID 18726017

- WO 2009152902, P. Wasserscheid, N. Paape, A. Boesmann, P. Schulz, "Ionic liquids", published 2009-12-23, assigned to Merck Patent GmbH

- J.H. Helberger; G. Manecke; R. Heyden (1949), "Zur Kenntnis organischer Sulfonsäuren III. Mitteilung: Die Alkylierungsreaktionen der Sultone", Liebigs Ann. Chem. (in German), vol. 565, no. 1, pp. 22–35, doi:10.1002/jlac.19495650104

- The United States Pharmacopeia 38th ed., National Formulary 33th (2015), United States Pharmacopeial Convention (ed.), Betadex Sulfobutyl Ether Sodium, Rockville, MD, pp. 6546–6548, ISBN 978-1-936424-34-4

{{citation}}: CS1 maint: location missing publisher (link) - T. Loftsson; D. Duchene (2007), "Cyclodextrins and their pharmaceutical applications", Int. J. Pharm., vol. 329, no. 1–2, pp. 1–11, doi:10.1016/j.ijpharm.2006.10.044, PMID 17137734

- S. Klein, T. Zöller (2008), "Cyclodextrine: Molekulare Zuckertüten für Arzneistoffe", Pharm. ZTG. (in German), vol. 26

- D.-Y. Ma; Y.-M. Zhang; J.-N. Xu (2016), "The synthesis and process optimization of sulfo butyl ether β-cyclodextrin derivatives", Tetrahedron, vol. 72, no. 22, pp. 3105–3112, doi:10.1016/j.tet.2016.04.039

- R. Challa; A. Ahuya; J. Ali; R.K. Khar (2005), "Cyclodextrins in drug delivery: an updated review", AAPS Pharm. Sci. Tech., vol. 6, no. 2, pp. E329–E357, doi:10.1208/pt060243, PMC 2750546, PMID 16353992