Hall–Héroult process

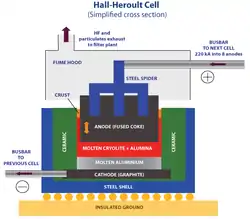

The Hall–Héroult process is the major industrial process for smelting aluminium. It involves dissolving aluminium oxide (alumina) (obtained most often from bauxite, aluminium's chief ore, through the Bayer process) in molten cryolite, and electrolyzing the molten salt bath, typically in a purpose-built cell. The Hall–Héroult process applied at industrial scale happens at 940–980 °C and produces 99.5–99.8% pure aluminium. Recycled aluminum requires no electrolysis, thus it does not end up in this process.[1]

Due to emission of carbon dioxide and fluorocarbons in the electrolytic reaction and consumption of large amounts of electrical energy in the process it contributes to climate change.[2][3]

Process

Difficulties faced

Elemental aluminium cannot be produced by the electrolysis of an aqueous aluminium salt, because hydronium ions readily oxidize elemental aluminium. Although a molten aluminium salt could be used instead, aluminium oxide has a melting point of 2072 °C[4] so electrolysing it is impractical. In the Hall–Héroult process, alumina, Al2O3, is dissolved in molten synthetic cryolite, Na3AlF6, to lower its melting point for easier electrolysis.[1] The carbon source is generally a coke (fossil fuel).[2]

Theory

In the Hall–Héroult process the following simplified reactions take place at the carbon electrodes:

Overall:

In reality, much more CO2 is formed at the anode than CO:

Pure cryolite has a melting point of 1009±1 °C. With a small percentage of alumina dissolved in it, its melting point drops to about 1000 °C. Besides having a relatively low melting point, cryolite is used as an electrolyte because, among other things, it also dissolves alumina well, conducts electricity, dissociates electrolytically at higher voltage than alumina, and also has a lower density than aluminum at the temperatures required by the electrolysis.[1]

Aluminium fluoride (AlF3) is usually added to the electrolyte. The ratio NaF/AlF3 is called the cryolite ratio and it is 3 in pure cryolite. In industrial production, AlF3 is added so that the cryolite ratio is 2–3 to further reduce the melting point, so that the electrolysis can happen at temperatures between 940 and 980 °C. The density of liquid aluminum is 2.3 g/ml at temperatures between 950 and 1000 °C. The density of the electrolyte should be less than 2.1 g/ml, so that the molten aluminum separates from the electrolyte and settles properly to the bottom of the electrolysis cell. In addition to AlF3, other additives like lithium fluoride may be added to alter different properties (melting point, density, conductivity etc.) of the electrolyte.[1]

The mixture is electrolysed by passing a low voltage (under 5 V) direct current at 100–300 kA through it. This causes liquid aluminium metal to be deposited at the cathode, while the oxygen from the alumina combines with carbon from the anode to produce mostly carbon dioxide.[1]

The theoretical minimum energy requirement for this process is 6.23 kWh/(kg of Al), but the process commonly requires 15.37 kWh.[5]

Cell operation

Cells in factories are operated 24 hours a day so that the molten material in them will not solidify. Temperature within the cell is maintained via electrical resistance. Oxidation of the carbon anode increases the electrical efficiency at a cost of consuming the carbon electrodes and producing carbon dioxide.[1]

While solid cryolite is denser than solid aluminium at room temperature, liquid aluminium is denser than molten cryolite at temperatures around 1,000 °C (1,830 °F). The aluminium sinks to the bottom of the electrolytic cell, where it is periodically collected. The liquid aluminium is removed from the cell via a siphon every 1 to 3 days in order to avoid having to use extremely high temperature valves and pumps. Alumina is added to the cells as the aluminum is removed. Collected aluminium from different cells in a factory is finally melted together to ensure uniform product and made into metal sheets. The electrolytic mixture is sprinkled with coke to prevent the anode's oxidation by the oxygen evolved.[1]

The cell produces gases at the anode. The exhaust is primarily CO2 produced from the anode consumption and hydrogen fluoride (HF) from the cryolite and flux (AlF3). In modern facilities, fluorides are almost completely recycled to the cells and therefore used again in the electrolysis. Escaped HF can be neutralized to its sodium salt, sodium fluoride. Particulates are captured using electrostatic or bag filters. The CO2 is usually vented into the atmosphere.[1]

Agitation of the molten material in the cell increases its production rate at the expense of an increase in cryolite impurities in the product. Properly designed cells can leverage magnetohydrodynamic forces induced by the electrolysing current to agitate the electrolyte. In non-agitating static pool cells, the impurities either rise to the top of the metallic aluminium, or sink to the bottom, leaving high-purity aluminium in the middle area.[1]

Electrodes

Electrodes in cells are mostly coke which has been purified at high temperatures. Pitch resin or tar is used as a binder. The materials most often used in anodes, coke and pitch resin, are mainly residues from the petroleum industry and need to be of high enough purity so no impurities end up into the molten aluminum or the electrolyte.[1]

There are two primary anode technologies using the Hall–Héroult process: Söderberg technology and prebaked technology.

In cells using Söderberg or self-baking anodes, there is a single anode per electrolysis cell. The anode is contained within a frame and, as the bottom of the anode turns mainly into CO2 during the electrolysis, the anode loses mass and, being amorphous, it slowly sinks within its frame. More material to the top of the anode is continuously added in the form of briquettes made from coke and pitch. The lost heat from the smelting operation is used to bake the briquettes into the carbon form required for the reaction with alumina. The baking process in Söderberg anodes during electrolysis releases more carcinogenic PAHs and other pollutants than electrolysis with prebaked anodes and, partially for this reason, prebaked anode-using cells have become more common in the aluminium industry. More alumina is added to the electrolyte from the sides of the Söderberg anode after the crust on top of the electrolyte mixture is broken.[1]

Prebaked anodes are baked in very large gas-fired ovens at high temperature before being lowered by various heavy industrial lifting systems into the electrolytic solution. There are usually 24 prebaked anodes in two rows per cell. Each anode is lowered vertically and individually by a computer, as the bottom surfaces of the anodes are eaten away during the electrolysis. Compared to Söderberg anodes, computer-controlled prebaked anodes can be brought closer to the molten aluminium layer at the bottom of the cell without any of them touching the layer and interfering with the electrolysis. This smaller distance decreases the resistance caused by the electrolyte mixture and increases the efficiency of prebaked anodes over Söderberg anodes. Prebake technology also has much lower risk of the anode effect (see below), but cells using it are more expensive to build and labor-intensive to use, as each prebaked anode in a cell needs to be removed and replaced once it has been used. Alumina is added to the electrolyte from between the anodes in prebake cells.[1]

Prebaked anodes contain a smaller percentage of pitch, as they need to be more solid than Söderberg anodes. The remains of prebaked anodes are used to make more new prebaked anodes. Prebaked anodes are either made in the same factory where electrolysis happens, or are brought there from elsewhere.[1]

The inside of the cell's bath is lined with cathode made from coke and pitch. Cathodes also degrade during electrolysis, but much more slowly than anodes do, and thus they need neither be as high in purity, nor be maintained as often. Cathodes are typically replaced every 2–6 years. This requires the whole cell to be shut down.[1]

Anode effect

The anode effect is a situation where too many gas bubbles form at the bottom of the anode and join, forming a layer. This increases the resistance of the cell, because smaller areas of the electrolyte touch the anode. These areas of the electrolyte and anode heat up when the density of the electric current of the cell focuses to go through only them. This heats up the gas layer and causes it to expand, thus further reducing the surface area where electrolyte and anode are in contact with each other. The anode effect decreases the energy-efficiency and the aluminium production of the cell. It also induces the formation of tetrafluoromethane (CF4) in significant quantities, increases formation of CO and, to a lesser extent, also causes the formation of hexafluoroethane (C2F6). CF4 and C2F6 are not CFCs, and, although not detrimental to the ozone layer, are still potent greenhouse gases. The anode effect is mainly a problem in Söderberg technology cells, not in prebaked.[1]

History

Existing need

Aluminium is the most abundant metallic element in the Earth's crust, but it is rarely found in its elemental state. It occurs in many minerals, but its primary commercial source is bauxite, a mixture of hydrated aluminium oxides and compounds of other elements such as iron.

Prior to the Hall–Héroult process, elemental aluminium was made by heating ore along with elemental sodium or potassium in a vacuum. The method was complicated and consumed materials that were in themselves expensive at that time. This meant that the cost to produce the small amount of aluminium made in the early 19th century was very high, higher than for gold or platinum. Bars of aluminium were exhibited alongside the French crown jewels at the Exposition Universelle of 1855, and Emperor Napoleon III of France was said to have reserved his few sets of aluminium dinner plates and eating utensils for his most honored guests.

Production costs using older methods did come down, but when aluminium was selected as the material for the cap/lightning rod to sit atop the Washington Monument in Washington, D.C., it was still more expensive than silver.[6]

Independent discovery

The Hall–Héroult process was invented independently and almost simultaneously in 1886 by the American chemist Charles Martin Hall[7] and by the Frenchman Paul Héroult[8]—both 22 years old. Some authors claim Hall was assisted by his sister Julia Brainerd Hall;[9] however, the extent to which she was involved has been disputed.[10][11] In 1888, Hall opened the first large-scale aluminium production plant in Pittsburgh. It later became the Alcoa corporation.

In 1997, the Hall–Héroult process was designated a National Historic Chemical Landmark by the American Chemical Society in recognition of the importance of the process in the commercialization of aluminum.[12]

Economic impact

Aluminium produced via the Hall–Héroult process, in combination with cheaper electric power, helped make aluminium (and incidentally magnesium) an inexpensive commodity rather than a precious metal.

This, in turn, helped make it possible for pioneers like Hugo Junkers to utilize aluminium and aluminium-magnesium alloys to make items like metal airplanes by the thousands, or Howard Lund to make aluminium fishing boats.[13] In 2012 it was estimated that 12.7 tons of CO2 emissions are generated per ton of aluminium produced.[14]

See also

References

- Totten, George E.; MacKenzie, D. Scott (2003). Handbook of Aluminum: Volume 2: Alloy production and materials manufacturing. vol. 2. New York, NY: Marcel Dekker, Inc. ISBN 0-8247-0896-2.

- Khaji, Khalil; Al Qassemi, Mohammed (2016). "The Role of Anode Manufacturing Processes in Net Carbon Consumption". Metals. 6 (6): 128. doi:10.3390/met6060128.

- Marks, Jerry; Roberts, Ruth; Bakshi, Vikram; Dolin, Eric (January 2000). "Perfluorocarbon (PFC) Generation During Primary Aluminum Production" (PDF).

{{cite journal}}: Cite journal requires|journal=(help) - Haynes, W.M. (2015). CRC Handbook of Chemistry and Physics (96th ed.). Boca Raton, FL: Taylor & Francis. ISBN 978-1-4822-6096-0.

- Obaidat, Mazin; Al-Ghandoor, Ahmed; Phelan, Patrick; Villalobos, Rene; Alkhalidi, Ammar (17 April 2018). "Energy and Exergy Analyses of Different Aluminum Reduction Technologies". Sustainability. 10 (4): 1216. doi:10.3390/su10041216.

- George J. Binczewski (1995). "The Point of a Monument: A History of the Aluminum Cap of the Washington Monument". JOM. 47 (11): 20–25. Bibcode:1995JOM....47k..20B. doi:10.1007/BF03221302. S2CID 111724924.

- US patent 400664, Charles Martin Hall, "Process of Reducing Aluminium from its Fluoride Salts by Electrolysis", issued 1889-04-02

- Héroult, Paul; French patent no. 175,711 (filed: 23 April 1886; issued: 1 September 1886).

- Kass-Simon, Gabrielle; Farnes, Patricia; Nash, Deborah (eds.) (1990). Women of Science: Righting the Record. Indiana University Press. pp. 173––176. ISBN 0-253-20813-0.

{{cite book}}:|first3=has generic name (help) - Sheller, Mimi (2014). Aluminum dreams : the making of light modernity. Cambridge, MA: MIT Press. p. 270. ISBN 978-0262026826. Retrieved 19 April 2016.

- Giddens, Paul H. (1953). "Alcoa, An. American Enterprise. By Charles C. Carr. (Book review)". Pennsylvania History. 20 (2): 209–210.

- "Production of Aluminum: The Hall–Héroult Process". National Historic Chemical Landmarks. American Chemical Society. Retrieved 2014-02-21.

- Lund Boat Company Founder Dies at 91

- Das, Subodh (2012). "Achieving Carbon Neutrality in the Global Aluminum Industry". JOM. 64 (2): 285–290. Bibcode:2012JOM....64b.285D. doi:10.1007/s11837-012-0237-0. ISSN 1047-4838. S2CID 59383624.

Further reading

- Grjotheim, U and Kvande, H., Introduction to Aluminium Electrolysis. Understanding the Hall–Heroult Process, Aluminium Verlag GmbH, (Germany), 1993, pp. 260.

- Prasad, Shiva (May–June 2000). "Studies on the Hall-Heroult Aluminum Electrowinning Process". Journal of the Brazilian Chemical Society. 11 (3): 245–251. doi:10.1590/S0103-50532000000300008.