Limonite

Limonite (/ˈlaɪməˌnaɪt/) is an iron ore consisting of a mixture of hydrated iron(III) oxide-hydroxides in varying composition. The generic formula is frequently written as FeO(OH)·nH2O, although this is not entirely accurate as the ratio of oxide to hydroxide can vary quite widely. Limonite is one of the three principal iron ores, the others being hematite and magnetite, and has been mined for the production of iron since at least 2500 BP.[4][5]

| Limonite | |

|---|---|

| |

| General | |

| Category | Amorphous, mineraloid |

| Formula (repeating unit) | FeO(OH)·nH2O |

| Strunz classification | Unclassified |

| Identification | |

| Color | Various shades of brown and yellow |

| Crystal habit | Fine grained aggregate, powdery coating |

| Cleavage | Absent |

| Fracture | Uneven |

| Mohs scale hardness | 4–5.5 |

| Luster | Earthy |

| Streak | Yellowish brown |

| Diaphaneity | Opaque |

| Specific gravity | 2.9–4.3 |

| Density | 2.7–4.3 g/cm3 |

| References | [1][2][3] |

Names

Limonite is named for the Ancient Greek word λειμών (leimṓn [leː.mɔ̌ːn]), meaning "wet meadow", or λίμνη (límnē [lím.nɛː]), meaning "marshy lake", as an allusion to its occurrence as bog iron ore in meadows and marshes.[6] In its brown form, it is sometimes called brown hematite[7] or brown iron ore.[8]

Characteristics

Limonite is relatively dense with a specific gravity varying from 2.7 to 4.3.[9] It is usually medium to dark yellowish brown in color. The streak of limonite on an unglazed porcelain plate is always yellowish brown, a character which distinguishes it from hematite with a red streak, or from magnetite with a black streak. The hardness is quite variable, ranging from 1 to 5. In thin section it appears as red, yellow, or brown and has a high index of refraction, 2.0 - 2.4. Limonite minerals are strongly birefringent, but grain sizes are usually too small for this to be detectable.[10]

Although originally defined as a single mineral, limonite is now recognized as a field term for a mixture of related hydrated iron oxide minerals,[11] among them goethite, lepidocrocite,[10] akaganeite,[12] and jarosite.[13] Determination of the precise mineral composition is practical only with X-ray diffraction techniques.[10] Individual minerals in limonite may form crystals, but limonite does not, although specimens may show a fibrous or microcrystalline structure,[14] and limonite often occurs in concretionary forms or in compact and earthy masses; sometimes mammillary, botryoidal, reniform or stalactitic. Because of its amorphous nature, and occurrence in hydrated areas limonite often presents as a clay or mudstone. However, there are limonite pseudomorphs after other minerals such as pyrite.[9] This means that chemical weathering transforms the crystals of pyrite into limonite by hydrating the molecules, but the external shape of the pyrite crystal remains. Limonite pseudomorphs have also been formed from other iron oxides, hematite and magnetite; from the carbonate siderite and from iron rich silicates such as almandine garnets.

Limonite deposited from mine runoff

Limonite deposited from mine runoff Galena and limonite

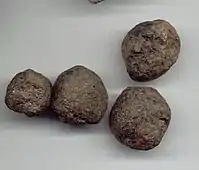

Galena and limonite Limonite pseudomorphs after garnet

Limonite pseudomorphs after garnet

Formation

Limonite usually forms from the hydration of hematite and magnetite, from the oxidation and hydration of iron rich sulfide minerals, and chemical weathering of other iron rich minerals such as olivine, pyroxene, amphibole, and biotite.[10] It is often the major iron component in lateritic soils, and limonite laterite ores are a source of nickel and potentially cobalt and other valuable metals, present as trace elements.[15][16] It is often deposited in run-off streams from mining operations.

Uses

Nickel-rich limonite ores represent the largest reserves of nickel. Such minerals are classified as lateritic nickel ore deposits.[17]

One of the first uses was as a pigment. The yellow form produced yellow ochre for which Cyprus was famous,[18] while the darker forms produced more earthy tones. Roasting the limonite changed it partially to hematite, producing red ochres, burnt umbers and siennas.[19] Bog iron ore and limonite mudstones are mined as a source of iron.

Iron caps or gossans of siliceous iron oxide typically form as the result of intensive oxidation of sulfide ore deposits.[20] These gossans were used by prospectors as guides to buried ore.

Limonite was mined for its ancillary gold content. The oxidation of sulfide deposits which contained gold, often resulted in the concentration of gold in the iron oxide and quartz of the gossans. The gold of the primary veins was concentrated into the limonites of the deeply weathered rocks. In another example the deeply weathered iron formations of Brazil served to concentrate gold with the limonite of the resulting soils.

History

Limonite was one of the earliest materials used as a pigment by humans, and can be seen in Neolithic cave paintings and pictographs.[21]

While the first iron ore was likely meteoric iron, and hematite was far easier to smelt, in Africa, where the first evidence of iron metallurgy occurs, limonite is the most prevalent iron ore. Before smelting, as the ore was heated and the water driven off, more and more of the limonite was converted to hematite. The ore was then pounded as it was heated above 1250 °C,[22] at which temperature the metallic iron begins sticking together and non-metallic impurities are thrown off as sparks. Complex systems developed, notably in Tanzania, to process limonite.[23] Nonetheless, hematite and magnetite remained the ores of choice when smelting was by bloomeries, and it was only with the development of blast furnaces in the 1st century BCE in China[24] and about 1150 CE in Europe,[25] that the brown iron ore of limonite could be used to best advantage.

Bog iron ore and limonite were mined in the US, but this ended with the development of advanced mining techniques.

Goldbearing limonite gossans were productively mined in the Shasta County, California mining district.[20] Similar deposits were mined near Rio Tinto in Spain and Mount Morgan in Australia. In the Dahlonega gold belt in Lumpkin County, Georgia gold was mined from limonite-rich lateritic or saprolite soil.

As saprolite deposits have been exhausted in many mining sites, limonite has become the most prominent source of nickel for use in energy dense batteries.

See also

Notes

- Limonite, Mindat.org, retrieved 2011-10-16

- "Mineral 1.0: Limonite". Retrieved 2011-10-16.

- "Limonite (hydrated iron oxide)". Retrieved 2011-10-16.

- MacEachern, Scott (1996) "Iron Age beginnings north of the Mandara Mountains, Cameroon and Nigeria" pp. 489–496 In Pwiti, Gilbert and Soper, Robert (editors) (1996) Aspects of African Archaeology: Proceedings of the Tenth Pan-African Congress University of Zimbabwe Press, Harare, Zimbabwe, ISBN 978-0-908307-55-5; archived here by Internet Archive on 11 March 2012

- Diop-Maes, Louise Marie (1996) "La question de l'Âge du fer en Afrique" ("The question of the Iron Age in Africa") Ankh 4/5: pp. 278–303, in French; archived here by Internet Archive on 25 January 2008

- Limonite, Mindat.org

- Jackson, Julia A., ed. (1997). "brown hematite". Glossary of Geology (4th ed.). Alexandria, Virginia: American Geological Institute. ISBN 0922152349.

- Jackson 1997, "brown iron ore".

- Northrop, Stuart A. (1959) "Limonite" Minerals of New Mexico (revised edition) University of New Mexico Press, Albuquerque, New Mexico, pp. 329–333, OCLC 2753195

- Nesse, William D. (2000). Introduction to mineralogy. New York: Oxford University Press. pp. 371–372. ISBN 9780195106916.

- Klein, Cornelis; Hurlbut, Cornelius S. Jr. (1993). Manual of mineralogy : (after James D. Dana) (21st ed.). New York: Wiley. ISBN 047157452X.

- Mackay, A. L. (December 1962). "β-Ferric oxyhydroxide—akaganéite". Mineralogical Magazine and Journal of the Mineralogical Society. 33 (259): 270–280. Bibcode:1962MinM...33..270M. doi:10.1180/minmag.1962.033.259.02.

- Zuo, Pengfei; Sun, Jiangtao; Liu, Xuefei; Hao, Jinhua; Zheng, Deshun; Li, Yu (November 2021). "Two types of jarosite in the early Cambrian sedimentary rocks: Insights for genesis and transformation of jarosite on Mars". Icarus. 369: 114651. Bibcode:2021Icar..36914651Z. doi:10.1016/j.icarus.2021.114651.

- Boswell, P. F. and Blanchard, Roland (1929) "Cellular structure in limonite" Economic Geology 24(8): pp. 791–796

- Rubisov, D.H; Krowinkel, J.M; Papangelakis, V.G (November 2000). "Sulphuric acid pressure leaching of laterites — universal kinetics of nickel dissolution for limonites and limonitic/saprolitic blends". Hydrometallurgy. 58 (1): 1–11. doi:10.1016/S0304-386X(00)00094-3.

- Gao, Jian-ming; Cheng, Fangqin (August 2018). "Study on the preparation of spinel ferrites with enhanced magnetic properties using limonite laterite ore as raw materials". Journal of Magnetism and Magnetic Materials. 460: 213–222. Bibcode:2018JMMM..460..213G. doi:10.1016/j.jmmm.2018.04.010. S2CID 125368631.

- Kerfoot, Derek G. E. (2005). "Nickel". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a17_157.

- Constantinou, G. and Govett, G. J. S. (1972). "Genesis of sulphide deposits, ochre and umber of Cyprus". Transactions of the Institution of Mining and Metallurgy. 81: pp. 34–46

- Heckel, George B. (1910) "Iron Oxide Paints". Paint, oil and drug review. 50(4): pp. 14–21, page 14

- Brown, G. Chester (1915) Mines and mineral resources of Shasta county, Siskiyou county, Trinity county California State Mining Bureau, California State Printing Office, Sacramento, California, pages 15–16, OCLC 5458708

- Wilford, John Noble (13 October 2011) "In African Cave, Signs of an Ancient Paint Factory" The New York Times; hardcopy published 14 October 2011 under title "African Cave, Ancient Paint Factory Pushes Human Symbolic Thought ‘Far Back’" New York edition page A-14; archived by WebCite page 1 and page 2 on 11 March 2012

- Iron oxide becomes metallic iron at roughly 1250°C, almost 300 degrees below iron's melting point of 1538°C.

- Schmidt, Peter and Avery, Donald H. (22 September 1978) "Complex Iron Smelting and Prehistoric Culture in Tanzania" Science201(4361): pp. 1085–1089

- Wagner, Donald B. (1999) "The earliest use of iron in China" Archived 2006-07-18 at the Wayback Machine pp. 1–9 In Young, Suzanne M. M. et al. (editors) (1999) Metals in Antiquity Archaeopress, Oxford, England, ISBN 978-1-84171-008-2

- Jockenhövel, Albrecht et al. (1997) "Archaeological Investigations on the Beginning of Blast Furnace-Technology in Central Europe" Abteilung für Ur- und Frühgeschichtliche Archäologie, Westfälische Wilhelms-Universität Münster; abstract published as: Jockenhövel, A. (1997) "Archaeological Investigations on the Beginning of Blast Furnace-Technology in Central Europe". In Crew, Peter and Crew, Susan (editors) (1997) Early Ironworking in Europe: Archaeology and Experiment: Abstracts of the International Conference at Plas Tan y Bwlch 19–25 Sept. 1997 (Plas Tan y Bwlch Occasional Papers No 3) Snowdonia National Park Study Centre, Gwynedd, Wales, pp. 56–58. OCLC 470699473. Archived here by WebCite on 11 March 2012