Cyclopentyl methyl ether

Cyclopentyl methyl ether (CPME), also known as methoxycyclopentane, is hydrophobic ether solvent. A high boiling point of 106 °C (223 °F) and preferable characteristics such as low formation of peroxides, relative stability under acidic and basic conditions, formation of azeotropes with water coupled with a narrow explosion range render CPME an attractive alternative to other ethereal solvents such as tetrahydrofuran (THF), 2-methyltetrahydrofuran (2-MeTHF), dioxane, and 1,2-dimethoxyethane (DME).[2]

| |

| Names | |

|---|---|

| Preferred IUPAC name

Methoxycyclopentane | |

| Other names

CPME | |

| Identifiers | |

3D model (JSmol) |

|

| ChemSpider | |

| ECHA InfoCard | 100.104.006 |

| EC Number |

|

PubChem CID |

|

| UNII | |

CompTox Dashboard (EPA) |

|

| |

| |

| Properties | |

| C6H12O | |

| Molar mass | 100.161 g·mol−1 |

| Appearance | Colorless clear liquid |

| Density | 0.8630 g/cm3 (20 °C) [1] |

| Melting point | −140 °C (−220 °F; 133 K) |

| Boiling point | 106 °C (223 °F; 379 K)[1] |

| 0.011 g/g | |

| Hazards | |

| GHS labelling: | |

| |

| Danger | |

| H225, H302, H312, H315, H319 | |

| P210, P233, P240, P241, P242, P243, P264, P270, P280, P301+P312, P302+P352, P303+P361+P353, P305+P351+P338, P312, P321, P322, P330, P332+P313, P337+P313, P362, P363, P370+P378, P403+P235, P501 | |

| NFPA 704 (fire diamond) | |

| Flash point | −1 °C (30 °F; 272 K) |

| Safety data sheet (SDS) | MSDS |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

Infobox references | |

Synthesis

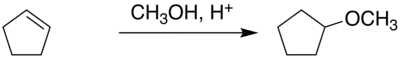

The synthesis of this compound can be done in two different ways:

(1) by methylation of the cyclopentanol.

(2) by the addition of methanol to the cyclopentene. This second method is better from the point of view of sustainable chemistry since it does not produce by-products.

Applications

Cyclopentyl methyl ether is used in organic synthesis, mainly as a solvent. However it is also useful in extraction, polymerization, crystallization and surface coating.

Some examples of reactions where it acts as a solvent are:

- Reactions involving alkali agents: nucleophilic substitutions of heteroatoms (alcohols and amines) [3]

- Lewis acids-mediated reactions: Beckmann Reaction, Friedel-Crafts Reaction etc.[4]

- Reactions using Organometallic reagents or basic agents: Claisen condensation, formation of enolates or Grignard reaction.[5]

- Reduction and oxidation.[6]

- Reactions with transition metal catalysts.[7]

- Reactions with azeotropical removal of water: acetalization, etc.[8]

Cyclopentyl methyl ether possesses characteristics that make it a potential alternate for other ethers. According to an evaluation of three chemistry journals from 2020, ethereal solvents have a share of 22–25% of all solvents employed.[9]

In contrast to water-soluble ethers like tetrahydrofuran and 1,4-dioxane, cyclopentyl methyl ether (CPME) - being hydrophobic - acts suitably as an extractant. In aqueous phases, only trace amounts of CPME remain due to its low solubility. CPME also exhibits stability at both low and high pH levels, even under elevated temperatures and extended contact times. It can form an azeotrope with water in a ratio of 83.7% CPME to 16.3% water at an azeotropic end temperature of 83 °C.[10] These properties enable CPME to function effectively as an entrainer during esterification processes[11] and acetalizations.[12]

Recently, investigations into the use of cyclopentyl methyl ether as an eco-friendly solvent in a wide range of chemical reactions, such as reductions, oxidations, and Grignard reactions, have been conducted.[13][14]

At present, however, the production of cyclopentyl methyl ether, which in multiple respects fulfills the criteria of a "green" chemical, still depends on cyclopentene derived from non-renewable, fossil-fuel sources. The platform chemical furfural can yield cyclopentanol in high yields through catalytic hydrogenation using a copper contact[15] or a nickelcobalt contact.[16] The resulting cyclopentanol can then be easily dehydrated to cyclopentene.

References

- Baird, Zachariah Steven; Uusi-Kyyny, Petri; Pokki, Juha-Pekka; Pedegert, Emilie; Alopaeus, Ville (6 Nov 2019). "Vapor Pressures, Densities, and PC-SAFT Parameters for 11 Bio-compounds". International Journal of Thermophysics. 40 (11): 102. Bibcode:2019IJT....40..102B. doi:10.1007/s10765-019-2570-9.

- Watanabe, Kiyoshi; Yamagiwa, Noriyuki; Torisawa, Yasuhiro (February 24, 2007). "Cyclopentyl Methyl Ether as a New and Alternative Process Solvent". Org. Process Res. Dev. 11 (2): 251–258. doi:10.1021/op0680136.

- Ether compounds and polymerizable compounds and manufacturing methods. By: Kiriki, Satoshi.Aug 3, 2015.JP 2015140302

- Torisawa, Yasuhiro (15 January 2007). "Conversion of indanone oximes into isocarbostyrils". Bioorganic & Medicinal Chemistry Letters. 17 (2): 453–455. doi:10.1016/j.bmcl.2006.10.022. PMID 17064893.

- Okabayashi, Tomohito; Iida, Akira; Takai, Kenta; Misaki, Tomonori; Tanabe, Yoo (September 18, 2007). "Practical and Robust Method for Regio- and Stereoselective Preparation of (E)-Ketene tert-Butyl TMS Acetals and β-Ketoester-derived tert-Butyl (1Z,3E)-1,3-Bis(TMS)dienol Ethers". The Journal of Organic Chemistry. 72 (21): 8142–8145. doi:10.1021/jo701456t. PMID 17877405.

- Shimada, Toyoshi; Suda, Masahiko; Nagano, Toyohiro; Kakiuchi, Kiyomi (October 22, 2005). "Facile Preparation of a New BINAP-Based Building Block, 5,5'-DiiodoBINAP, and Its Synthetic Application". The Journal of Organic Chemistry. 70 (24): 10178–10181. doi:10.1021/jo0517186. PMID 16292868.

- Molander, Gary A.; Elia, Maxwell D. (November 3, 2006). "Suzuki−Miyaura Cross-Coupling Reactions of Benzyl Halides with Potassium Aryltrifluoroborates". The Journal of Organic Chemistry. 71 (24): 9198–9202. doi:10.1021/jo061699f. PMC 2515367. PMID 17109547.

- Azzena, Ugo; Carraro, Massimo; Mamuye, Ashenafi Damtew; Murgia, Irene; Pisano, Luisa; Zedde, Giuseppe (17 April 2015). "Cyclopentyl methyl ether – NH4X: a novel solvent/ catalyst system for low impact acetalization reactions". Green Chemistry. 17 (6): 3281–3284. doi:10.1039/c5gc00465a.

- A. Jordan, C.G.J. Hall, L.R. Thorp, H.F. Sneddon (2022), "Replacement of less-preferred dipolar aprotic and ethereal solvents in synthetic organic chemistry with more sustainable alternatives", Chem. Rev., vol. 122, pp. 6749–6794, doi:10.1021/acs.chemrev.1c00672

{{citation}}: CS1 maint: multiple names: authors list (link) - "Novel hydrophobic ether solvent – Cyclopentyl methyl ether – CPME – Technical Data" (PDF). Zeon Corporation. June 2018. Retrieved 2022-10-20.

- D. Rigo, G. Firani, A. Perosa, M. Selva (2019), "Acid-Catalyzed Reactions of Isopropenyl Esters and Renewable Diols: A 100% Carbon Efficient Transesterification/Acetalization Tandem Sequence, from Batch to Continuous Flow", ACS Sustainable Chem. Eng., vol. 7, no. 23, pp. 18810–18818, doi:10.1021/acssuschemeng.9b03359

{{citation}}: CS1 maint: multiple names: authors list (link) - U. Azzena, M. Carraro, A.D. Mamuye, I. Murgia, L. Pisano, G. Zedde (2015), "Cyclopentyl methyl ether–NH4X: a novel solvent/catalyst system for low impact acetalization reactions", Green Chem., vol. 17, no. 6, pp. 3281–3284, doi:10.1039/C5GC00465A

{{citation}}: CS1 maint: multiple names: authors list (link) - "Synthetic Applications with Cyclopentyl methyl ether (CPME), Ver. 2.0" (PDF). Zeon Corporation. September 2018. Retrieved 2022-10-20.

- U. Azzena, M. Carraro, L. Pisano, S. Monticelli, R. Bartolotta, V. Pace (2019), "Cyclopentyl Methyl Ether: An Elective Ecofriendly Ethereal Solvent in Classical and Modern Organic Chemistry", ChemSusChem, vol. 12, no. 1, pp. 40–70, doi:10.1002/cssc.201801768

{{citation}}: CS1 maint: multiple names: authors list (link) - N. Pino, G. Hincapié, D. López (2018), "Selective Catalytic Route for the Synthesis of High-Density Biofuel Using Biomass-Derived Compounds", Energy & Fuels, vol. 32, no. 1, pp. 561–573, doi:10.1021/acs.energyfuels.7b03256

{{citation}}: CS1 maint: multiple names: authors list (link) - Q. Guo, X. Hou, W. Xiu, J. Liu (2022), "Efficient conversion of furfural to cyclopentanol over lignin activated carbon supported Ni–Co catalyst", RSC Adv., vol. 12, pp. 11843–11852, doi:10.1039/D2RA00016D

{{citation}}: CS1 maint: multiple names: authors list (link)