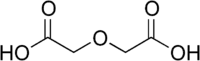

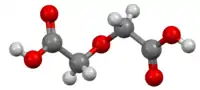

Diglycolic acid

Diglycolic acid is an aliphatic dicarboxylic acid, its acidity is between the one of acetic acid and oxalic acid.[1] It is formed in the oxidation of diethylene glycol in the body and can lead to severe complications with fatal outcome.[2]

| |

| |

| Names | |

|---|---|

| Preferred IUPAC name

2,2′-Oxydiacetic acid | |

| Identifiers | |

3D model (JSmol) |

|

| ChemSpider | |

| ECHA InfoCard | 100.003.476 |

| EC Number |

|

PubChem CID |

|

| UNII | |

CompTox Dashboard (EPA) |

|

| |

| |

| Properties | |

| C4H6O5 | |

| Molar mass | 134.09 g/mol |

| Melting point | 140-144°C |

| Acidity (pKa) | 2.79, 3.93 (20°C) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

Infobox references | |

Preparation

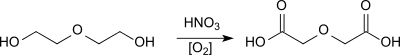

Oxidation of diethylene glycol with concentrated nitric acid was described by A. Wurtz in 1861[3]

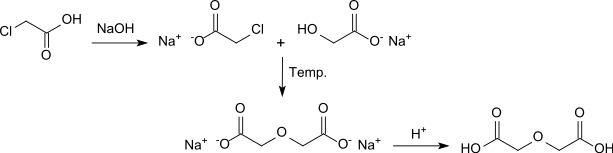

In parallel, W. Heintz reported the synthesis of diglycolic acid from chloroacetic acid by heating with sodium hydroxide solution.[4]

In a version with barium hydroxide solution as an alkaline medium, diglycolic acid is obtained in 68% yield after acidification.[5]

The yields of the described reactions are unsatisfactory for use on a technical scale.

The single-stage nitric acid process gives even in the presence of an oxidation catalyst (vanadium(V)oxide) yields of only 58-60%.[6] In a multi-stage process of nitric acid oxidation at 70 °C and multiple crystallization steps, evaporation of the residues and return of the diethylene glycol-containing mother liquor, product yields of up to 99% (based on diethylene glycol) can be achieved.[7]

The oxidation of diethylene glycol with air, oxygen or ozone avoids the use of expensive nitric acid and prevents the inevitable formation of nitrous gases.[8] In the presence of a platinum catalyst, yields of 90% can be obtained by air oxidation.[9]

On a bismuth platinum contact catalyst, yields of 95% are to be achieved under optimized reaction conditions.[10]

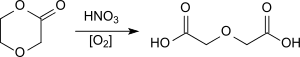

The oxidation of 1,4-dioxan-2-one (p-dioxanone, a lactone which is used as a comonomer in biodegradable polyesters with nitric acid or dinitrogen tetroxide) is also described with yields of up to 75%.[11]

Properties

Diglycolic acid is readily water soluble and crystallizes from water in monoclinic prisms as a white, odorless solid. At an air humidity of more than 72% and 25 °C the monohydrate is formed. The commercial product is the anhydrous form as a free-flowing flakes.[12]

Application

Diesters of diglycolic acid with (branched) higher alcohols can be used as softeners for polyvinyl chloride (PVC) with comparable properties as di-n-octyl phthalate (DOP).[13]

Basic solutions of diglycolic acid are described for the removal of limescale deposits in gas and oil bores, as well as in systems such as heat exchangers or steam boilers.[14]

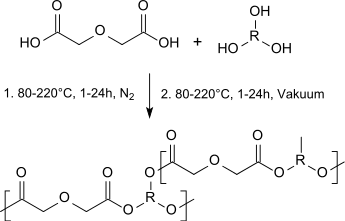

Diglycolic acid can be used as a diester component in homo- and copolymeric polyesters (so-called polyalkylene diglycolates) which are biocompatible and biodegradable and can be used alone or in blends with aliphatic polyesters as tissue adhesives, cartilage substitutes or as implant materials:[15]

References

- L. Bhattacharyya, J. Rohrer, ed. (2012), Appendix 1: DISSOCIATION CONSTANTS (pKa) OF ORGANIC ACIDS (AT 20 °C), in Applications of Ion Chromatography for Pharmaceutical and Biological Products, John Wiley & Sons, Inc., doi:10.1002/9781118147009.app1

- A.A. Roscher, E. Jussek, T. Noguchi, S. Franklin (1975), "Fatal Accidental Diglycolic Acid Intoxication" (PDF), Bull. Soc. Pharm. Environ. Pathol., vol. III, no. 4, archived from [PDF the original] on 2017-06-29, retrieved 2017-02-04

{{citation}}: Check|url=value (help)CS1 maint: multiple names: authors list (link) - A. Wurtz (1861), "Umwandlung des Aethylens zu complicirten organischen Säuren", Liebigs Ann. Chem. (in German), vol. 117, no. 1, pp. 136–140, doi:10.1002/jlac.18611170114

- W. Heintz (1862), "Ueber die Diglycolsäure (Paraäpfelsäure)", Ann. Phys. (in German), vol. 191, no. 2, pp. 280–295, doi:10.1002/andp.18621910206

- K.E. Füger (1959), [PDF Synthese und katalytische Reduktion von Glykolsäure und Glykolsäureestern, Promotionsarbeit ETH Zürich] (in German), Juris-Verlag

{{citation}}: Check|url=value (help) - C. Erk (1991), "Condensation of diglycolic acid dichloride with polyglycols, 5. An improved synthesis of cyclic polyether-esters by cyclization", Liebigs Ann. Chem., vol. 1991, no. 10, pp. 1083–1084, doi:10.1002/jlac.1991199101186

- US 4066691, M. Schröder, "Process for the production of pure diglycolic acid by oxidation if diethylene glycol with nitric acid", published 1978-1-3, assigned to Chemische Werke Hüls AG

- US 3879452, G.E. Brown, Jr., "Method for making diglycolic acid, dipropionic acid and the salts there f", published 1975-4-22, assigned to Conen Corp.

- US 4256916, D.L. Morris, W.J. Gammans, J.D. Holmes, "Oxidation of polyethylene glycols to dicarboxylic acids", published 1981-3-17, assigned to Eastman Kodak Co.

- Y-Y. Zhang, Z.-Y. Liang, Y.-D. Zhang (May 2012), [PDF "Preparation of Diglycolic Acid via Oxidation of Diethylene Glycol with Molecular Oxygen"], Fine Chemicals

{{citation}}: Check|url=value (help)CS1 maint: multiple names: authors list (link) - US 3952054, C.Y. Shen, "Process for preparing diglycolic acid", published 1976-4-20, assigned to Monsanto Co.

- W.M. Bruner, L.T. Sherwood, Jr. (1949), "Diglycolic acid – a new commercial dibasic acid", Ind. Eng. Chem., vol. 41, no. 8, pp. 1653–1656, doi:10.1021/ie50476a032

{{citation}}: CS1 maint: multiple names: authors list (link) - US 3173888, P.T. von Bramer, R.M. Simons, "Diesters of diglycolic acid and vinyl chloride polymers plastized therewith", published 1965-3-16, assigned to Eastman Kodak Co.

- US 3639279, T.R. Gardner, R.M. Lasater, J.A. Knox, "Scale removal composition and method using salt of diglycolic acid and base at pH above 5", published 1972-2-1, assigned to Halliburton Co.

- US 5696178, K. Cooper, A. Scopelianos, "Absorbable polyalkylene diglycolates", published 1997-12-9, assigned to Ethicon, Inc.