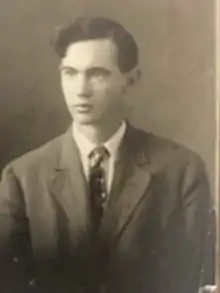

Earl A. Thompson

Earl Avery Thompson (July 1, 1891 – April 20, 1967) was an American engineer and inventor who had a goal to make driving the automobile safer by reducing the effort required to shift the manual transmission of the day. Thompson even wanted to automate the process of shifting the transmission. Two of his most notable achievements towards that goal are listed on this page:

Early life and career

Thompson was born in Elgin, Oregon, on July 1, 1891. He was educated at Oregon State College where he majored in mechanical and electrical engineering. Thompson worked for General Motors Corporation (GM) from 1929–1940. Thompson left GM May 1, 1940, to begin his own business, the E.A. Thompson Manufacturing Co. In Ferndale, Michigan. Thompson manufactured the Thompson Automatic Profiling Milling machine which is used by manufacturers in the production of arms, plane, tank, and gun parts.[1] Thompson died April 20, 1967, at the age of 75 in Bloomfield Hills, Michigan.

Notable achievements

The synchromesh transmission

Thompson's 1918 invention of a synchromesh manual transmission using a tapered cone synchronizer to prevent gear clash (US Patent US1435430 in March 1922[2]) would make shifting a manual transmission faster, easier and safer. In April of 1922 Thompson, armed with drawings and data for a prototype synchromesh transmission, set out for Detroit to sell it to the automobile industry. But the automobile manufacturers were not impressed; their customers, he was told, were satisfied with transmissions just as they were. Thompson persisted. After several trips between Oregon and Detroit, and months spent improving the design, and two more patent applications,[3][4] he was finally able to arrange a meeting with Lawrence Fisher, managing director of Cadillac Motor Car Division and Ernest Seaholm, Cadillac's chief engineer. They were interested in the idea, and (in 1924) Thompson was retained as a consultant while the transmission was perfected[5] (10 models in all).

The first cars to use Thompson's synchromesh transmission design were Cadillac and LaSalle cars in 1928, then Buick 8's in 1931.[6] Thompson sold his synchromesh transmission patents to GM in 1924[7] and 1930 for a reported $1 million.

Thompson became an employee of Cadillac Motor Car Division on September 1, 1929, and was appointed to be assistant chief engineer. Thompson continued improving the design of the synchronizer. In 1933. Thompson began working on the development of an automatically shifting transmission. Thompson left Cadillac in 1934 and joined the General Motors Corporation (GM) Engineering Department.[8]

GM Automatic Safety Transmission Development

In 1934 at the GM Engineering Department, Thompson became the project leader of a group of four engineers including Ralph F. Beck, William L. Carnegie, Walter B. Herndon, and Maurice S. Rosenberger. This group developed the Automatic Safety Transmission,[9] an optional semi-automatic transmission for some 1937–1939 Oldsmobile and 1938 Buick vehicles.[10]

GM Hydra-Matic Transmission Development

In June 1936 a fifth engineer, "O.K." Oliver K. Kelley, joined Thompson's group; he was transferred from G.M.C. Truck and Coach Division where the development of a hydraulic torque converter drive for a transit bus was proceeding.[11] Thompson's group combined a fluid coupling with a unique hydraulically controlled, automatically shifting 4-speed planetary transmission, introduced as an option on 1940 Oldsmobiles as Hydra-Matic, the world's first mass-produced fully automatic transmission. The 1940 Hydra-Matic transmission would continue to be refined and produced for another 16 years, including wartime use in some military vehicles.

Awards

- Recipient of the Elmer A. Sperry Award in 1963 for design and development of the first successful automatic automobile transmission

Manual transmission patents

Automatic transmission patents

Thompson was awarded 22 patents.[12] Nine of his patents were directly related to the development of the Hydra-Matic transmission

- 1933/1942 US Patent US2285760[13] for Change Speed Gearing with Automatic Overdrive

- 1934/1940 US Patent US2195605[14] for Change Speed Transmission and Control

- 1935/1940 US Patent US2193304[15] for Change Speed Mechanism and Control

- 1937/1940 US Patent US2193305[16] for Brake and Clutch Capacity Control

- 1937/1940 US Patent US2193524[17] for Change Speed Gearing and Control

- 1937/1944 US Patent US2362418[18] for Clutch and Gearing Control

- 1938/1940 US Patent US2204872[19] for Change Speed Gearing and Control

- 1940/1945 US Patent US2380680[20] for Clutch and Control

- 1940/1947 US Patent US2430258[21] for Rotary Hydraulic Coupling of the Turbine Type

External links

- "Ferndale 1918-1943 25 Years of Progress | PDF | M 1 (Michigan Highway) | Forging". Scribd.

- "Automatic gear-shifting mechanism for sliding gear transmission".

- "Automatic gear shifting mechanism".

- "Transmission".

- "ECL 147: Automatic Transmission Development". 1970.

- "23 May 1931, 33 – Honolulu Star-Bulletin at". Newspapers.com. 1931-05-23. Retrieved 2022-06-05.

- Gott, Phillip G (1991). Changing Gears (1st ed.). USA: Society of Automotive Engineers. p. 88. ISBN 1-56091-099-2.

- "Earl Thompson".

- "'NO CLUTCH TO PRESS! NO GEARS TO SHIFT!' | Automotive News". 13 December 2005.

- Daniel Strohl (April 13, 2008). "SIA Flashback - Almost Automatic". hemmings.com.

- "Yellow Coach Part 2, Yellow Coach Mfg. Co., Yellow Truck and Coach, Yellow Bus, Greyhound Bus, Silversides, GMC Truck, CCKW, DUKW, General Motors". CoachBuilt.com. Retrieved 2022-06-05.

- "ininventor:Earl A Thompson - Google Search". www.google.com.

- "Change speed gearing with automatic overdrive".

- "Change-speed transmission and control".

- "Change-speed mechanism and control".

- "Brake and clutch capacity control".

- "Change speed gearing and control".

- "Clutch and gearing control".

- "Change speed gearing and control".

- "Clutch and control".

- "Rotary hydraulic coupling of the turbine type".