Linseed oil

Linseed oil, also known as flaxseed oil or flax oil (in its edible form), is a colourless to yellowish oil obtained from the dried, ripened seeds of the flax plant (Linum usitatissimum). The oil is obtained by pressing, sometimes followed by solvent extraction.

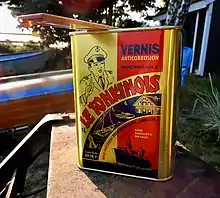

Owing to its polymer-forming properties, linseed oil is often blended with combinations of other oils, resins or solvents as an impregnator, drying oil finish or varnish in wood finishing, as a pigment binder in oil paints, as a plasticizer and hardener in putty, and in the manufacture of linoleum. Linseed oil use has declined over the past several decades with increased availability of synthetic alkyd resins—which function similarly but resist yellowing.[1]

Linseed oil is an edible oil in demand as a dietary supplement, as a source of α-Linolenic acid, an omega-3 fatty acid. In parts of Europe, it is traditionally eaten with potatoes and quark.

Structure and composition

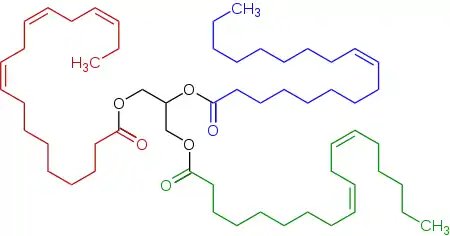

Representative triglyceride found in a linseed oil, a triester (triglyceride) derived of linoleic acid, alpha-linolenic acid, and oleic acid.

Representative triglyceride found in a linseed oil, a triester (triglyceride) derived of linoleic acid, alpha-linolenic acid, and oleic acid.

Linseed oil is a triglyceride, like other fats. Linseed oil is distinctive for its unusually large amount of α-linolenic acid, which oxidises in air. The fatty acids in a typical linseed oil are of the following types:[2]

- The triply unsaturated α-linolenic acid (51.9–55.2%),

- The saturated acids palmitic acid (about 7%) and stearic acid (3.4–4.6%),

- The monounsaturated oleic acid (18.5–22.6%),

- The doubly unsaturated linoleic acid (14.2–17%).

Drying properties

Having a high content of di- and tri-unsaturated esters, linseed oil is susceptible to polymerization reactions upon exposure to oxygen in air. This polymerization, which is called autoxidation, results in the rigidification of the material.[3] To prevent premature drying, linseed oil-based products (oil paints, putty) are stored in airtight containers.

Rags soaked with linseed oil pose fire hazard because they provide a large surface area for rapid oxidation. The oxidation of linseed oil is exothermic, which may lead to spontaneous combustion.[4] In 1991, One Meridian Plaza, in Philadelphia, was severely damaged in a fire, in which three firefighters perished, thought to be caused by rags soaked with linseed oil.[5]

Applications

Most applications of linseed oil exploit its drying properties, i.e., the initial material is liquid or at least pliable and the aged material is rigid but not brittle. The water-repelling (hydrophobic) nature of the resulting hydrocarbon-based material is advantageous.[3]

Paint binder

Linseed oil is the carrier used in oil paint. It can also be used as a painting medium, making oil paints more fluid, transparent and glossy. It is available in varieties such as cold-pressed, alkali-refined, sun-bleached, sun-thickened, and polymerised (stand oil). The introduction of linseed oil was a significant advance in the technology of oil painting.

Putty

Traditional glazing putty, consisting of a paste of chalk powder and linseed oil, is a sealant for glass windows that hardens within a few weeks of application and can then be painted over. The durability of putty is owed to the drying properties of linseed oil.

Wood finish

When used as a wood finish, linseed oil dries slowly and shrinks little upon hardening. A linseed oil finish is easily scratched and liquid water penetrates a linseed oil finish in mere minutes, and water vapour bypasses it almost completely.[6] Garden furniture treated with linseed oil may develop mildew. Oiled wood may be yellowish and is likely to darken with age. Even though the oil feels dry to the touch, studies show linseed oil does not fully cure.[7]

Linseed oil is a common finish for wooden items, though very fine finish may require months to obtain. Studies show the fatty-acid structure of linseed oil has problems cross-linking and oxidizing, frequently turning black.[8]

Gilding

Boiled linseed oil is used as sizing in traditional oil gilding to adhere sheets of gold leaf to a substrate (parchment, canvas, Armenian bole, etc.). It has a much longer working time than water-based size and gives a firm smooth surface that is adhesive enough in the first 12–24 hours after application to cause the gold to attach firmly to the intended surface.

Linoleum

Linseed oil is used to bind wood dust, cork particles, and related materials in the manufacture of the floor covering linoleum. After its invention in 1860 by Frederick Walton, linoleum, or "lino" for short, was a common form of domestic and industrial floor covering from the 1870s until the 1970s, when it was largely replaced by PVC ("vinyl") floor coverings.[9] However, since the 1990s, linoleum is returning to favor, being considered more environmentally sound than PVC.[10] Linoleum has given its name to the printmaking technique linocut, in which a relief design is cut into the smooth surface and then inked and used to print an image. The results are similar to those obtained by woodcut printing.

Nutritional supplement and food

Raw cold-pressed linseed oil – commonly known as flax seed oil in nutritional contexts – is easily oxidized, and rapidly becomes rancid, with an unpleasant odour, unless refrigerated. Linseed oil is not generally recommended for use in cooking. In one study, the content of Alpha linolenic acid (ALA) in whole flaxseeds did not decrease after heating the seeds to temperatures of up to 178 °C (352.4 °F) for one and a half hours.[11]

Food-grade flaxseed oil is cold-pressed, obtained without solvent extraction, in the absence of oxygen, and marketed as edible flaxseed oil. Fresh, refrigerated and unprocessed, linseed oil is used as a nutritional supplement and is a traditional European ethnic food, highly regarded for its nutty flavor. Regular flaxseed oil contains between 57% and 71% polyunsaturated fats (alpha-linolenic acid, linoleic acid).[12] Plant breeders have developed flaxseed with both higher ALA (70%)[12] and very low ALA content (< 3%).[13] The USFDA granted generally recognized as safe (GRAS) status for high alpha linolenic flaxseed oil.[14]

Nutrient content

| Typical fatty acid content | % [15] | % European[16] |

|---|---|---|

| Palmitic acid | 6.0 | 4.0–6.0 |

| Stearic acid | 2.5 | 2.0–3.0 |

| Arachidic acid | 0.5 | 0–0.5 |

| Palmitoleic acid | - | 0–0.5 |

| Oleic acid | 19.0 | 10.0–22.0 |

| Eicosenoic acid | - | 0–0.6 |

| Linoleic acid | 24.1 | 12.0–18.0 |

| Alpha-linolenic acid | 47.4 | 56.0–71.0 |

| Other | 0.5 | - |

Nutrition information from the Flax Council of Canada.[17]

Per 1 tbsp (14 g)

Flax seed oil contains no significant amounts of protein, carbohydrates or fibre.

Comparison to other vegetable oils

| Type | Processing treatment[20] | Saturated fatty acids | Monounsaturated fatty acids | Polyunsaturated fatty acids | Smoke point | ||||

|---|---|---|---|---|---|---|---|---|---|

| Total[18] | Oleic acid (ω-9) | Total[18] | α-Linolenic acid (ω-3) | Linoleic acid (ω-6) | ω-6:3 ratio | ||||

| Avocado[21] | 11.6 | 70.6 | 52–66 [22] | 13.5 | 1 | 12.5 | 12.5:1 | 250 °C (482 °F)[23] | |

| Brazil nut[24] | 24.8 | 32.7 | 31.3 | 42.0 | 0.1 | 41.9 | 419:1 | 208 °C (406 °F)[25] | |

| Canola[26] | 7.4 | 63.3 | 61.8 | 28.1 | 9.1 | 18.6 | 2:1 | 204 °C (400 °F)[27] | |

| Coconut[28] | 82.5 | 6.3 | 6 | 1.7 | 175 °C (347 °F)[25] | ||||

| Corn[29] | 12.9 | 27.6 | 27.3 | 54.7 | 1 | 58 | 58:1 | 232 °C (450 °F)[27] | |

| Cottonseed[30] | 25.9 | 17.8 | 19 | 51.9 | 1 | 54 | 54:1 | 216 °C (420 °F)[27] | |

| Cottonseed[31] | hydrogenated | 93.6 | 1.5 | 0.6 | 0.2 | 0.3 | 1.5:1 | ||

| Flaxseed/linseed[32] | 9.0 | 18.4 | 18 | 67.8 | 53 | 13 | 0.2:1 | 107 °C (225 °F) | |

| Grape seed | 10.4 | 14.8 | 14.3 | 74.9 | 0.15 | 74.7 | very high | 216 °C (421 °F)[33] | |

| Hemp seed[34] | 7.0 | 9.0 | 9.0 | 82.0 | 22.0 | 54.0 | 2.5:1 | 166 °C (330 °F)[35] | |

| High-oleic safflower oil[36] | 7.5 | 75.2 | 75.2 | 12.8 | 0 | 12.8 | very high | 212 °C (414 °F)[25] | |

| Olive, Extra Virgin[37] | 13.8 | 73.0 | 71.3 | 10.5 | 0.7 | 9.8 | 14:1 | 193 °C (380 °F)[25] | |

| Palm[38] | 49.3 | 37.0 | 40 | 9.3 | 0.2 | 9.1 | 45.5:1 | 235 °C (455 °F) | |

| Palm[39] | hydrogenated | 88.2 | 5.7 | 0 | |||||

| Peanut[40] | 16.2 | 57.1 | 55.4 | 19.9 | 0.318 | 19.6 | 61.6:1 | 232 °C (450 °F)[27] | |

| Rice bran oil | 25 | 38.4 | 38.4 | 36.6 | 2.2 | 34.4[41] | 15.6:1 | 232 °C (450 °F)[42] | |

| Sesame[43] | 14.2 | 39.7 | 39.3 | 41.7 | 0.3 | 41.3 | 138:1 | ||

| Soybean[44] | 15.6 | 22.8 | 22.6 | 57.7 | 7 | 51 | 7.3:1 | 238 °C (460 °F)[27] | |

| Soybean[45] | partially hydrogenated | 14.9 | 43.0 | 42.5 | 37.6 | 2.6 | 34.9 | 13.4:1 | |

| Sunflower[46] | 8.99 | 63.4 | 62.9 | 20.7 | 0.16 | 20.5 | 128:1 | 227 °C (440 °F)[27] | |

| Walnut oil[47] | unrefined | 9.1 | 22.8 | 22.2 | 63.3 | 10.4 | 52.9 | 5:1 | 160 °C (320 °F)[48] |

Additional uses

- Animal care products

- Bicycle maintenance as a thread fixative, rust inhibitor and lubricant

- Composition ornament for moulded decoration

- Earthen floors

- Animal feeds

- Industrial lubricant

- Leather treatment

- Oilcloth

- Particle detectors[49]

- Textiles

- Wood preservation (including as an active ingredient of Danish oil)

- Cookware seasoning

- Plant protection[50]

Modified linseed oils

Stand oil

Stand oil is generated by heating linseed oil near 300 °C for a few days in the complete absence of air. Under these conditions, the polyunsaturated fatty esters convert to conjugated dienes, which then undergo Diels-Alder reactions, leading to crosslinking. The product, which is highly viscous, gives highly uniform coatings that "dry" to more elastic coatings than linseed oil itself. Soybean oil can be treated similarly, but converts more slowly. On the other hand, tung oil converts very quickly, being complete in minutes at 260 °C. Coatings prepared from stand oils are less prone to yellowing than are coatings derived from the parent oils.[51]

Boiled linseed oil

Boiled linseed oil is a combination of raw linseed oil, stand oil (see above), and metallic oil drying agents (catalysts to accelerate drying).[51] In the Medieval era, linseed oil was boiled with lead oxide (litharge) to give a product called boiled linseed oil.[52] The lead oxide forms lead "soaps" (lead oxide is alkaline) that promote hardening (polymerisation) of linseed oil by reaction with atmospheric oxygen. Heating shortens its drying time.

Raw linseed oil

Raw linseed oil is the base oil, unprocessed and without driers or thinners. It is mostly used as a feedstock for making a boiled oil. It does not cure sufficiently well or quickly to be regarded as a drying oil.[53] Raw linseed is sometimes used for oiling cricket bats to increase surface friction for better ball control.[54] It was also used to treat leather flat belt drives to reduce slipping.

References

- Jones, Frank N. (2003). "Alkyd Resins". Ullmann's Encyclopedia of Industrial Chemistry. doi:10.1002/14356007.a01_409. ISBN 978-3527306732.

- Vereshchagin, A. G.; Novitskaya, Galina V. (1965). "The triglyceride composition of linseed oil". Journal of the American Oil Chemists' Society. 42 (11): 970–974. doi:10.1007/BF02632457. PMID 5898097. S2CID 29785363.

- Poth, Ulrich (2001). "Drying Oils and Related Products". Ullmann's Encyclopedia of Industrial Chemistry. doi:10.1002/14356007.a09_055. ISBN 9783527303854.

- Ettling, Bruce V.; Adams, Mark F. (1971). "Spontaneous combustion of linseed oil in sawdust". Fire Technology. 7 (3): 225. doi:10.1007/BF02590415. S2CID 109500727.

- Routley, J. Gordon; Jennings, Charles; Chubb, Mark (February 1991), "Highrise Office Building Fire One Meridian Plaza Philadelphia, Pennsylvania" (PDF), Report USFA-TR-049, Federal Emergency Management Agency

- Flexner, Bob. Understanding Wood Finishing. Reader's Digest Association, Inc., 2005, p. 75.

- Lazzari, Massimo; Chiantore, Oscar (1999). "Drying and oxidative degradation of linseed oil" (PDF). Polymer Degradation and Stability. 65 (2): 303–313. doi:10.1016/S0141-3910(99)00020-8.

- Kerschner, Richard L.; Ravenel, Nancie (2013). "Here We Go 'Round Again: Cleaning Linseed Oil from Carousel Animalsatthe Shelburne Museum". Journal of the American Institute for Conservation. 45 (3): 201–210. doi:10.1179/019713606806112450. S2CID 191561961.

- S. Diller and J. Diller, Craftsman's Construction Installation Encyclopedia, Craftsman Book Company, 2004, p. 503

- Julie K. Rayfield, The Office Interior Design Guide: An Introduction for Facility and Design Professionals, John Wiley & Sons, 1994, p. 209

- Chen, Z. Y.; Ratnayake, W. M. N.; Cunnane, S. C. (1994). "Oxidative stability of flaxseed lipids during baking". Journal of the American Oil Chemists' Society. 71 (6): 629–632. doi:10.1007/BF02540591. S2CID 84981982.

- Morris, Diane H. (2007). "Chapter 1: Description and Composition of Flax; In: Flax – A Health and Nutrition Primer". Flax Council of Canada. Retrieved 16 September 2019.

- Thompson, Lilian U.; Cunnane, Stephen C., eds. (2003). Flaxseed in human nutrition (2nd ed.). AOCS Press. pp. 8–11. ISBN 978-1-893997-38-7.

- "U.S. FDA/CFSAN Agency Response Letter GRAS Notice No. GRN 00256". U.S. FDA/CFSAN. Retrieved 2013-01-29.

- "Linseed" (PDF). Interactive European Network for Industrial Crops and their Applications. October 14, 2002. Archived from the original (PDF) on September 27, 2007. Retrieved 2008-01-24.

- Deutsche Gesellschaft für Fettwissenschaft (see 'Leinöl Europa': Fettsäurezusammensetzung wichtiger pflanzlicher und tierischer Speisefette und -öle Archived 2008-12-22 at the Wayback Machine (PDF)

- "Flax - A Healthy Food". Flax Council of Canada. Archived from the original on 2011-07-06. Retrieved 2008-01-24.

- "US National Nutrient Database, Release 28". United States Department of Agriculture. May 2016. All values in this table are from this database unless otherwise cited or when italicized as the simple arithmetic sum of other component columns.

- "Fats and fatty acids contents per 100 g (click for "more details"). Example: Avocado oil (user can search for other oils)". Nutritiondata.com, Conde Nast for the USDA National Nutrient Database, Standard Release 21. 2014. Retrieved 7 September 2017. Values from Nutritiondata.com (SR 21) may need to be reconciled with most recent release from the USDA SR 28 as of Sept 2017.

- "USDA Specifications for Vegetable Oil Margarine Effective August 28, 1996" (PDF).

- "Avocado oil, fat composition, 100 g". US National Nutrient Database, Release 28, United States Department of Agriculture. May 2016. Retrieved 6 September 2017.

- Ozdemir F, Topuz A (2004). "Changes in dry matter, oil content and fatty acids composition of avocado during harvesting time and post-harvesting ripening period" (PDF). Food Chemistry. Elsevier. pp. 79–83. Archived from the original (PDF) on 2020-01-16. Retrieved 15 January 2020.

- Wong M, Requejo-Jackman C, Woolf A (April 2010). "What is unrefined, extra virgin cold-pressed avocado oil?". Aocs.org. The American Oil Chemists' Society. Retrieved 26 December 2019.

- "Brazil nut oil, fat composition, 100 g". US National Nutrient Database, Release 28, United States Department of Agriculture. May 2016. Retrieved 6 September 2017.

- Katragadda HR, Fullana A, Sidhu S, Carbonell-Barrachina ÁA (2010). "Emissions of volatile aldehydes from heated cooking oils". Food Chemistry. 120: 59–65. doi:10.1016/j.foodchem.2009.09.070.

- "Canola oil, fat composition, 100 g". US National Nutrient Database, Release 28, United States Department of Agriculture. May 2016. Retrieved 6 September 2017.

- Wolke RL (May 16, 2007). "Where There's Smoke, There's a Fryer". The Washington Post. Retrieved March 5, 2011.

- "Coconut oil, fat composition, 100 g". US National Nutrient Database, Release 28, United States Department of Agriculture. May 2016. Retrieved 6 September 2017.

- "Corn oil, industrial and retail, all purpose salad or cooking, fat composition, 100 g". US National Nutrient Database, Release 28, United States Department of Agriculture. May 2016. Retrieved 6 September 2017.

- "Cottonseed oil, salad or cooking, fat composition, 100 g". US National Nutrient Database, Release 28, United States Department of Agriculture. May 2016. Retrieved 6 September 2017.

- "Cottonseed oil, industrial, fully hydrogenated, fat composition, 100 g". US National Nutrient Database, Release 28, United States Department of Agriculture. May 2016. Retrieved 6 September 2017.

- "Linseed/Flaxseed oil, cold pressed, fat composition, 100 g". US National Nutrient Database, Release 28, United States Department of Agriculture. May 2016. Retrieved 6 September 2017.

- Garavaglia J, Markoski MM, Oliveira A, Marcadenti A (2016). "Grape Seed Oil Compounds: Biological and Chemical Actions for Health". Nutrition and Metabolic Insights. 9: 59–64. doi:10.4137/NMI.S32910. PMC 4988453. PMID 27559299.

- Callaway J, Schwab U, Harvima I, Halonen P, Mykkänen O, Hyvönen P, Järvinen T (April 2005). "Efficacy of dietary hempseed oil in patients with atopic dermatitis". The Journal of Dermatological Treatment. 16 (2): 87–94. doi:10.1080/09546630510035832. PMID 16019622. S2CID 18445488.

- Melina V. "Smoke points of oils" (PDF). veghealth.com. The Vegetarian Health Institute.

- "Safflower oil, salad or cooking, high oleic, primary commerce, fat composition, 100 g". US National Nutrient Database, Release 28, United States Department of Agriculture. May 2016. Retrieved 6 September 2017.

- "Olive oil, salad or cooking, fat composition, 100 g". US National Nutrient Database, Release 28, United States Department of Agriculture. May 2016. Retrieved 6 September 2017.

- "Palm oil, fat composition, 100 g". US National Nutrient Database, Release 28, United States Department of Agriculture. May 2016. Retrieved 6 September 2017.

- "Palm oil, industrial, fully hydrogenated, filling fat, fat composition, 100 g". US National Nutrient Database, Release 28, United States Department of Agriculture. May 2016. Retrieved 6 September 2017.

- "Oil, peanut". FoodData Central. usda.gov.

- Orthoefer FT (2005). "Chapter 10: Rice Bran Oil". In Shahidi F (ed.). Bailey's Industrial Oil and Fat Products. Vol. 2 (6th ed.). John Wiley & Sons, Inc. p. 465. doi:10.1002/047167849X. ISBN 978-0-471-38552-3.

- "Rice bran oil". RITO Partnership. Retrieved 22 January 2021.

- "Oil, sesame, salad or cooking". FoodData Central. fdc.nal.usda.gov. 1 April 2019.

- "Soybean oil, salad or cooking, fat composition, 100 g". US National Nutrient Database, Release 28, United States Department of Agriculture. May 2016. Retrieved 6 September 2017.

- "Soybean oil, salad or cooking, (partially hydrogenated), fat composition, 100 g". US National Nutrient Database, Release 28, United States Department of Agriculture. May 2016. Retrieved 6 September 2017.

- "FoodData Central". fdc.nal.usda.gov.

- "Walnut oil, fat composition, 100 g". US National Nutrient Database, United States Department of Agriculture.

- "Smoke Point of Oils". Baseline of Health. Jonbarron.org.

- Goldberg, Leah (2008-10-26). "Measuring Rate Capability of a Bakelite-Trigger RPC Coated with Linseed Oil". APS Division of Nuclear Physics Meeting Abstracts: DA.033. Bibcode:2008APS..DNP.DA033G.

- Breiing, Vera; Hillmer, Jennifer; Schmidt, Christina; Petry, Michael; Behrends, Brigitte; Steiner, Ulrike; Kraska, Thorsten; Pude, Ralf (2021). "Fungicidal Efficacy of Drying Plant Oils in Green Beans against Bean Rust (Uromyces appendiculatus)". Plants. 10 (1): 143. doi:10.3390/plants10010143. PMC 7827098. PMID 33445566.

- Poth, Ulrich (2001). "Drying Oils and Related Products". Ullmann's Encyclopedia of Industrial Chemistry. doi:10.1002/14356007.a09_055. ISBN 3527306730.

- Merrifield, Mary P. (2012). Medieval and Renaissance Treatises on the Arts of Painting: Original Texts. Dover Publications, Inc. ISBN 978-0486142241.

- Franks, George (1999). Classic Wood Finishing (2nd ed.). Sterling. p. 96. ISBN 978-0806970639.

- "Caring for your Bat". Gunn & Moore. Archived from the original on 16 August 2017.

Further reading

- Knight, William A.; Mende, William R. (2000). Staining and Finishing for Muzzleloading Gun Builders. privately published. Archived from the original on 2013-05-30.

External links

- . Collier's New Encyclopedia. 1921.