Oilfield scale inhibition

Oilfield scale inhibition is the process of preventing the formation of scale from blocking or hindering fluid flow through pipelines, valves, and pumps used in oil production and processing. Scale inhibitors (SIs) are a class of specialty chemicals that are used to slow or prevent scaling in water systems.[1][2] Oilfield scaling is the precipitation and accumulation of insoluble crystals (salts) from a mixture of incompatible aqueous phases in oil processing systems.[2] Scale is a common term in the oil industry used to describe solid deposits that grow over time, blocking and hindering fluid flow through pipelines, valves, pumps etc. with significant reduction in production rates and equipment damages.[2][3] Scaling represents a major challenge for flow assurance in the oil and gas industry. Examples of oilfield scales are calcium carbonate (limescale), iron sulfides, barium sulfate and strontium sulfate. Scale inhibition encompasses the processes or techniques employed to treat scaling problems.[2]

Background

The three prevailing water-related problems that upset oil companies today are corrosion, gas hydrates and scaling in production systems.[2][4] The reservoir water has a high composition of dissolved minerals equilibrated over millions of years at constant physicochemical conditions. As the reservoir fluids are pumped from the ground, changes in temperature, pressure and chemical composition shift the equilibria and cause precipitation and deposition of sparingly soluble salts that build up over time with the potential of blocking vital assets in the oil production setups.[5] Scaling can occur at all stages of oil/gas production systems (upstream, midstream and downstream) and causes blockages of well-bore perforations, casing, pipelines, pumps, valves etc. Severe scaling issues have been reported in Russia and certain North Sea production systems.[6]

Types of scales

Two main classifications of scales are known; inorganic and organic scales and the two types are mutually inclusive, occurring simultaneously in the same system, referred to as mixed scale.[4][5] Mixed scales may result in highly complex structured scales that are difficult to treat. Such scales require aggressive, severe and sometimes costly remediation techniques.[4] Paraffin wax, asphaltenes and gas hydrates are the most often encountered organic scales in the oil industry. This article focuses on the simplest and common form of scales encountered; inorganic scales.

Inorganic scale

Inorganic scales refer to mineral deposits that occur when the formation water mixes with different brines such as injection water. The mixing changes causes reaction between incompatible ions and changes the thermodynamic and equilibrium state of the reservoir fluids. Supersaturation and subsequent deposition of the inorganic salts occur. The most common types of inorganic scales known to the oil/gas industry are carbonates and sulfates; sulfides and chlorites are often encountered.

While the solubility of most inorganic salts (NaCl, KCl, ...) increases with temperature (endothermic dissolution reaction), some inorganic salts such as calcium carbonate and calcium sulfate have also a retrograde solubility, i.e., their solubility decreases with temperature. In the case of calcium carbonate, it is due to the degassing of CO2 whose solubility decreases with temperature as is the case for most of the gases (exothermic dissolution reaction in water). In calcium sulfate, the reason is that the dissolution reaction of calcium sulfate itself is exothermic and therefore is favored when the temperature decreases (then, the dissolution heat is more easily evacuated; see Le Chatelier's principle). In other terms, the solubility of calcium carbonate and calcium sulfate increases at low temperature and decreases at high temperature, as it is also the case for calcium hydroxide (portlandite), often cited as a didactic case study to explain the reason of retrograde solubility.

| Name | Chemical Formula | Mineral |

|---|---|---|

| Calcium carbonate | CaCO3 | Calcite, aragonite |

| Calcium sulfate | CaSO4 | Anhydrite, gypsum (CaSO4 · 2 H2O), bassanite (hemihydrate form) (CaSO4 · 0.5 H2O) |

| Calcium oxalate | CaC2O4 | Beerstone |

| Barium sulfate | BaSO4 | Barite |

| Magnesium hydroxide | Mg(OH)2 | Brucite |

| Magnesium oxide | MgO | Periclase |

| Silicates | Me(SinOx) · y H2O | Serpentine, acmite, gyrolite, gehlenite, amorphous silica, quartz, cristobalite, pectolite |

| Aluminium oxy-hydroxides | AlO(OH) | Boehmite, gibbsite, diaspore, corundum |

| Aluminosilicates | AlxSiyOz | Analcite, cancrinite, noselite |

| Copper | Cu | Metallic copper, cuprite (Cu2O), tenorite (Cu ) |

| Magnetite | Fe3O4 | Fe2+ and Fe3+ mixed oxide: FeO + Fe2O3 |

| Nickel ferrite | NiFe2O4 | Trevorite, Ni2+ and Fe3+ mixed oxide: NiO + Fe2O3 |

| Phosphates | Ca10(PO4)6(OH)2 | Hydroxyapatite |

Calcium carbonate scale

Water, noted for its high solvation power can dissolve certain gases such as carbon dioxide (CO2) to form aqueous CO2(aq). Under the right conditions of temperature and/or pressure, H2O and CO2(aq) molecules react to yield carbonic acid (H2CO3) whose solubility increases at low temperature and high pressure. The slightest changes in pressure and temperature dissolves H2CO3(aq) in water according to equation (3) to form hydronium and bicarbonate (HCO3−(aq)) ions.

- CO2(aq) + H2O(l) ↔ H2CO3(aq)

- H2CO3(aq) ↔ H+(aq) + HCO3−(aq)

- 2 HCO3−(aq) ↔ CO32−(aq) + H2O(l) + CO2(g)

- Ca2+(aq) + CO32−(aq) ↔ CaCO3(s)

The two reactions (2) and (4) describe the equilibrium between bicarbonate ions (HCO3−), which are highly soluble in water and calcium carbonate (CaCO3) salt. According to Le Chatelier's principle, drilling operations and extraction of the oil from the well bore decreases the pressure of the formation and the equilibrium shifts to the right (3) to increase the production of CO2 to offset the change in pressure. After years of oil production, wells may experience significant pressure drops resulting in large CaCO3 deposits as the equilibrium shifts to offset the pressure changes.[4]

Sulfate scales

Sulfates of Group (II) metal ions (M2+), generally decrease in solubility down the group. The most difficult scales to remove are those of Barium sulfate because of its high insolubility forming very hard scale deposits. A general representation of the reaction is summarized in reaction:

5. M2+(aq) + SO42−(aq) → MSO4(s)

Sulfate scale usually forms when formation water and injected seawater mix together.[2] The relationship between these and the degree of supersaturation is crucial in estimating the amount of sulfate salts that will precipitate in the system.[7] Seawater has a high concentration of sulfate ions and mixing with formation water with many Ca2+ and other M2+ ions in the formation water. Severe problems with sulfate scale are common in reservoirs where seawater has been injected to enhance oil recovery.[2]

Due to its relatively high solubility in water, Calcium sulfate is the easiest sulfate scale to remove chemically as compared to strontium and barium sulfate.[2] Scale crystals are initially dispersed in production systems until accumulation of stable crystals of insoluble sulfates and scale growth occur at nucleation centers.[8] Uneven pipeline surfaces and production equipment such as pumps and valves cause rapid scale growth to levels that can block pipelines.[4]

The scaling-tendency of an oil-well can be predicted based on the prevailing conditions such as pH, temperature, pressure, ionic strength and the mole fraction of CO2 in the vapor and aqueous phases.[9] For instance the saturation index for CaCO3 scale is calculated using the formula;

Fs= {[Ca2+][CO32−]}/Ksp

Where Fs is the scale saturation ratio, defined as the ratio of the activity product to the solubility product of the salt. Activity is defined as the product of the activity coefficients and the concentrations of Ca2+ and SO42− ions. The ionic strength is a measure of the concentration of the dissociated ions dissolved in water also called as “total dissolved solids” (TDS).[9]

Scale remediation

Different oilfield scale remediation techniques are known but majority are based on three basic themes:

- Sulfate ion sequestering from sea injection waters

- Chemical or mechanical Scale removal/dissolution

- Application of Scale Inhibitors (SIs) for scale prevention

The first two methods may be used for short-term treatment and effective for mild-scaling conditions,[2] however, continuous injection or chemical scale squeeze treatment with SIs have been proven over the years to be the most efficient and cost-effective preventative technique.[10]

Scale inhibitors

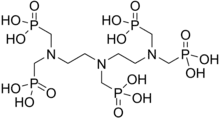

Scale inhibitors are specialty chemicals that are added to oil production systems to delay, reduce and/or prevent scale deposition.[4] acrylic acid polymers, maleic acid polymers and phosphonates have been used extensively for scale treatment in water systems due to their excellent solubility, thermal stability and dosage efficiency.[11][12] In the water treatment industry, the major classes of SIs have inorganic phosphate, organophosphorous and organic polymer backbones and common examples are PBTC (phosphonobutane-1,2,4-tricarboxylic acid), ATMP (amino-trimethylene phosphonic acid) and HEDP (1-hydroxyethylidene-1,1-diphosphonic acid), polyacrylic acid (PAA), phosphinopolyacrylates (such as PPCA), polymaleic acids (PMA), maleic acid terpolymers (MAT), sulfonic acid copolymers, such as SPOCA (sulfonated phosphonocarboxylic acid), polyvinyl sulfonates. Two common oilfield mineral SIs are Poly-Phosphono Carboxylic acid (PPCA) and Diethylenetriamine- penta (methylene phosphonic acid) (DTPMP).[13]

Inhibition of calcium carbonate scale deposition and crystal studies of its polymorphs have been conducted.[14][15][16] Different SIs are designed for specific scaling conditions and biodegradability properties.[14] The inhibitor molecules essentially bind ions in aqueous phase of production fluids that could potentially precipitate as scales. For instance, to bind positively charged ions in the water, anions must be present in the inhibitor molecular backbone structure and vice versa. Group (II) metal ions are commonly sequestered by SIs with the following functionalities;[4]

- Phosphonate ions (-PO3H−)

- Phosphate ions (-OPO3H−)

- Phosphonate ions (-PO2H−)

- Sulphonate ions (-SO3−)

- Carboxylate ions (-CO2−)

A SI with a combination of two or more of these functional groups is more efficient in managing scale problems. Usually the sodium salts of the carboxylic derivatives are synthesized as the anionic derivatives and are known to be the most effective due to their high solubilities.[4] Interactions of these functional groups tend to prevent the crystal growth sites using dissociated or un-dissociated groups. The dissociation state is determined by the pH of the system, hence knowledge of the pKa values of the chemicals are important for different pH environments.[17] Again, the inhibition efficiency of the SI depends on its compatibility with other production chemicals such as corrosion inhibitors.[18]

Environmental considerations

Generally, the environmental impacts of SIs are complicated further by combination of other chemicals applied through exploratory, drilling, well-completion and start-up operations. Produced fluids, and other wastes from oil and gas operations with high content of different toxic compounds are hazardous and harmful to human health, water supplies, marine and freshwater organisms.[19][20] For instance trails of increased turbidity resulting from oil and gas exploratory activities on the eastern shelf of Sakhalin in Russia have been reported with consequential adverse effects on salmon, cod and littoral amphipods.[21]

Efforts to develop more environmentally friendly SIs have been made since the late 1990s and an increasing number of such SIs are becoming commercially available.[4] Recent environmental awareness over the past 15 years has resulted in the production and application of more environmentally friendly SIs, otherwise called 'Green Scale Inhibitors' (GSI).[22] These GSIs are designed to have reduced bio-accumulating and high biodegradability properties and therefore reduce pollution of the waters around oil production systems.[4][22][23] Phosphate ester SIs, commonly employed for treating calcium carbonate scales are known to be environmentally friendly but poor inhibition efficiency.[23] Release of SIs containing Nitrogen and Phosphorus distorts the natural equilibrium of the immediate water body with adverse effects on aquatic life.[23]

Another alternative, polysaccharide SIs meet the requirements for environmentally friendly materials; they contain no Phosphorus or Nitrogen and are noted for their non-toxic, renewable, and biodegradable properties.[24][25] Carboxymethyl inulin (CMI), which is isolated from the roots of Inula helenium has been used in oil exploration and its very low toxicity[26] and crystal growth inhibition power[27] has been reported for treating calcite scales.[28] Examples of poorly biodegradable SIs such as the amino-phosphonate and acrylate-based SIs are being phased-out by stringent environmental regulations as demonstrated in the North sea by Norway zero discharge policy.[21]

Another modern alternative to SI use for environmental protection is the development of materials or coatings that intrinsically resist formation of inorganic scale to begin with. A variety of strategies can be used to accomplish this aim, including engineering of wettability properties and engineering of epitaxial properties to prevent mineral growth or to make minerals easier to remove following growth. Recent work has demonstrated that some classes of hydrophobic and superhydrophobic surfaces can cause self-ejection of scale grown during evaporation [29]

References

- Alzahrani, Salem; Mohammad, Abdul Wahab (2014-12-01). "Challenges and trends in membrane technology implementation for produced water treatment: A review". Journal of Water Process Engineering. 4: 107–133. doi:10.1016/j.jwpe.2014.09.007.

- W. Frenier, Wayne (2008). Formation, removal, and inhibition of inorganic scale in the oilfield environment. Society of Petroleum Engineers. ISBN 978-1555631406.

- Liang, Bin; Pan, Kai; Li, Li; Giannelis, Emmanuel P.; Cao, Bing (2014-08-15). "High performance hydrophilic pervaporation composite membranes for water desalination". Desalination. 347: 199–206. doi:10.1016/j.desal.2014.05.021.

- Kelland, M. A. (6 Feb 2014). Production chemicals for the oil and gas industry. CRC press. ISBN 9781439873793.

- Wayne W Frenier, Murtaza Ziauddin, N. Wolf (Editor), Ryan Hartman (Editor) (2008). Formation, removal, and inhibition of inorganic scale in the oilfield environment. Society of Petroleum Engineers. ISBN 978-1555631406.

{{cite book}}:|last=has generic name (help)CS1 maint: multiple names: authors list (link) - Mitchell, R.W; Grist, D.M.; Boyle, M.J. (May 1980). "Chemical Treatments Associated with North Sea Projects". Society of Petroleum Engineers. 32 (5): 904–912. doi:10.2118/7880-PA.

- Collins, I.R. (2002-01-01). "A New Model for Mineral Scale Adhesion". All Days. doi:10.2118/74655-ms. ISBN 9781555639426.

{{cite book}}:|journal=ignored (help) - Crabtree, M., Eslinger, D., Fletcher, P., Miller, M., Johnson, A., & King, G. (1999). "Fighting Scale- prevention and removal". Oilfield Review. 11 (3): 30–45.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - Oddo, J.E.; Tomson, M.B. (1994-02-01). "Why Scale Forms in the Oil Field and Methods To Predict It". SPE Production & Facilities. 9 (1): 47–54. doi:10.2118/21710-pa. ISSN 1064-668X.

- Laing, N.; Graham, G.M.; Dyer, S.J. (2003-01-01). Barium Sulphate Inhibition in Subsea Systems - The Impact of Cold Seabed Temperatures on the Performance of Generically Different Scale Inhibitor Species. doi:10.2118/80229-ms. ISBN 9781555639556.

{{cite book}}:|journal=ignored (help) - Amjad, Zahid; Koutsoukos, Petros G. (2014-02-17). "Evaluation of maleic acid based polymers as scale inhibitors and dispersants for industrial water applications". Desalination. 335 (1): 55–63. doi:10.1016/j.desal.2013.12.012.

- Shakkthivel, P.; Vasudevan, T. (2006-10-02). "Acrylic acid-diphenylamine sulphonic acid copolymer threshold inhibitor for sulphate and carbonate scales in cooling water systems". Desalination. 197 (1): 179–189. doi:10.1016/j.desal.2005.12.023.

- Bezemer, Cornelis; Bauer, Karl A. (1969-04-01). "Prevention of Carbonate Scale Deposition: A Well-Packing Technique with Controlled Solubility Phosphates". Journal of Petroleum Technology. 21 (4): 505–514. doi:10.2118/2176-pa. ISSN 0149-2136.

- Shi, Wenyan; Xia, Mingzhu; Lei, Wu; Wang, Fengyun (2013-08-01). "Molecular dynamics study of polyether polyamino methylene phosphonates as an inhibitor of anhydrite crystal". Desalination. 322: 137–143. doi:10.1016/j.desal.2013.05.013.

- Fried, Ruth; Mastai, Yitzhak (2012-01-01). "The effect of sulfated polysaccharides on the crystallization of calcite superstructures". Journal of Crystal Growth. 338 (1): 147–151. Bibcode:2012JCrGr.338..147F. doi:10.1016/j.jcrysgro.2011.09.044.

- Shi, Wen-Yan; Ding, Cheng; Yan, Jin-Long; Han, Xiang-Yun; Lv, Zhi-Min; Lei, Wu; Xia, Ming-Zhu; Wang, Feng-Yun (2012-04-02). "Molecular dynamics simulation for interaction of PESA and acrylic copolymers with calcite crystal surfaces". Desalination. 291: 8–14. doi:10.1016/j.desal.2012.01.019.

- Graham, GM Boak, LS Sorbie, KS (2003). "The influence of formation calcium and magnesium on the effectiveness of generically different barium sulphate oilfield scale inhibitors". Soc Petroleum Eng. 18: 28–44 – via Science Citation Index.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - Lawless, T.A.; Bourne, H.M.; Bolton, J.R. (1993-01-01). Examining the Potential for Corrosion Inhibitor and Scale Inhibitor Compatibility in a Multifunctional Squeeze Strategy. doi:10.2118/25167-ms. ISBN 9781555634926.

{{cite book}}:|journal=ignored (help) - "Drilling Waste Streams from Offshore Oil and Gas Installations". www.offshore-environment.com. Retrieved 2016-11-22.

- Davies, Michael ; P. J. B. Scott (2006). Oilfield water technology. NACE International. pp. 523–32. ISBN 978-1-57590-204-3.

{{cite book}}: CS1 maint: multiple names: authors list (link) - Knudsen, B.L.; Hjelsvold, M.; Frost, T.K.; Svarstad, M.B.E.; Grini, P.G.; Willumsen, C.F.; Torvik, H. (2004-01-01). "Meeting the Zero Discharge Challenge for Produced Water". All Days. doi:10.2118/86671-ms. ISBN 9781555639815.

{{cite book}}:|journal=ignored (help) - Boak, Lorraine S.; Sorbie, Ken (2010-11-01). "New Developments in the Analysis of Scale Inhibitors". SPE Production & Operations. 25 (4): 533–544. doi:10.2118/130401-pa. ISSN 1930-1855.

- Jordan, Myles M.; Sorhaug, Eyvind; Marlow, David (2012-11-01). "Red vs. Green Scale Inhibitors for Extending Squeeze life--A Case Study From the North Sea, Norwegian Sector--Part II". SPE Production & Operations. 27 (4): 404–413. doi:10.2118/140752-pa. ISSN 1930-1855.

- Pro, Danièle; Huguet, Samuel; Arkoun, Mustapha; Nugier-Chauvin, Caroline; Garcia-Mina, José Maria; Ourry, Alain; Wolbert, Dominique; Yvin, Jean-Claude; Ferrières, Vincent (2014-11-04). "From algal polysaccharides to cyclodextrins to stabilize a urease inhibitor" (PDF). Carbohydrate Polymers. 112: 145–151. doi:10.1016/j.carbpol.2014.05.075. PMID 25129728.

- Liu, Jun; Willför, Stefan; Xu, Chunlin (2015-01-01). "A review of bioactive plant polysaccharides: Biological activities, functionalization, and biomedical applications". Bioactive Carbohydrates and Dietary Fibre. 5 (1): 31–61. doi:10.1016/j.bcdf.2014.12.001.

- Johannsen, F. R (2003-01-01). "Toxicological profile of carboxymethyl inulin". Food and Chemical Toxicology. 41 (1): 49–59. doi:10.1016/S0278-6915(02)00213-2. PMID 12453728.

- Kirboga, Semra; Öner, Mualla (2013-04-16). "Investigation of calcium carbonate precipitation in the presence of carboxymethyl inulin". CrystEngComm. 15 (18): 3678. doi:10.1039/c3ce27022j. ISSN 1466-8033.

- Kırboga, Semra; Öner, Mualla (2012-03-01). "The inhibitory effects of carboxymethyl inulin on the seeded growth of calcium carbonate". Colloids and Surfaces B: Biointerfaces. 91: 18–25. doi:10.1016/j.colsurfb.2011.10.031. PMID 22079106.

- McBride, Samantha; Lake, John; Varanasi, Kripa (2023-04-07). "Self-ejection of salts and other foulants from superhydrophobic surfaces to enable sustainable anti-fouling". The Journal of Chemical Physics. 158 (13): 134721. doi:10.1063/5.0142428. PMID 37031132.