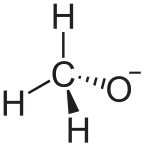

Potassium methoxide

Potassium methoxide is the alkoxide of methanol with the counterion potassium and is used as a strong base and as a catalyst for transesterification, in particular for the production of biodiesel.

| |||

| |||

| Names | |||

|---|---|---|---|

| IUPAC name

Potassium methoxide | |||

| Systematic IUPAC name

Potassium methylate | |||

| Identifiers | |||

| |||

3D model (JSmol) |

|||

| ChemSpider | |||

| ECHA InfoCard | 100.011.579 | ||

| EC Number |

| ||

PubChem CID |

|||

| UNII | |||

| UN number | 3206 | ||

CompTox Dashboard (EPA) |

|||

| |||

| |||

| Properties | |||

| CH3KO | |||

| Molar mass | 70.132 | ||

| Hazards | |||

| GHS labelling: | |||

| |||

| Danger | |||

| H228, H251, H290, H302, H314 | |||

| P210, P234, P235+P410, P240, P241, P260, P264, P270, P280, P301+P312, P301+P330+P331, P303+P361+P353, P304+P340, P305+P351+P338, P310, P321, P330, P363, P370+P378, P390, P404, P405, P407, P413, P420, P501 | |||

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

Infobox references | |||

Preparation

The preparation of potassium methoxide can be achieved on the laboratory scale by the (strongly exothermic) reaction of metallic potassium and methanol upon the release of equimolar amounts of hydrogen.[1]

The reaction of metal hydrides (potassium hydride) with methanol forming potassium methoxide is also possible but less important.

The exothermic reaction of potassium hydroxide with methanol leads in an equilibrium reaction to potassium methanolate and water (avoiding formation of highly inflammable hydrogen gas). In a continuous process the formed water must be removed permanently.[2]

The complete removal of the water is critical for the reaction conversion, due to the pronounced hygroscopy of potassium hydroxide, which contains about 10% of water.[3] The significantly higher dissolution rate of potassium hydroxide in methanol compared to sodium hydroxide is advantageous.

On a large scale, potassium methoxide is produced by decomposing potassium amalgam with methanol, which is produced by the chloralkali-electrolysis of potassium chloride by the amalgam process. Impurities of the resulting potassium methoxide in methanol with metallic mercury can be eliminated by ultrafiltration.[4] Solid potassium methoxide is obtained by distilling off the methanol. Because of their simpler production and better handling for chemical purposes solutions of potassium methanolate ( 25 to 32% by weight) are preferably used, which were continuously withdrawn from the amalgam process.

The displacement of the amalgam process by the ecologically and economically superior membrane process for the preparation of the mass chemicals sodium hydroxide and potassium hydroxide will make this standard production process for the production of alkali metal alkoxides in future useless.[5]

Properties

Potassium methoxide is a white to yellowish, hygroscopic, odorless crystalline powder which reacts violently with water forming potassium hydroxide and methanol. The aqueous solutions obtained are highly basic and have a corrosive effect. The substance is classified as an inflammable solid with a spontaneous ignition temperature of 70 °C.[6]

The human toxicity and ecotoxicity evaluation of potassium methoxide is based on the properties of the decomposition products potassium hydroxide and methanol during hydrolysis in the aqueous medium.

Use

The carbonylation of methanol with carbon monoxide to methyl formate (methyl methanoate) is catalyzed by strong bases, such as potassium methoxide.[7][8]

The main application of potassium methoxide is use as basic transesterification catalyst in biodiesel synthesis (as a 25-32% methanolic solution). Triglycerides of vegetable and animal origin are reacted with methanol in the presence of alkali metal methanolates to form the corresponding fatty methyl esters.[9][3]

Potassium methoxide allows a facilitated formation of fatty soaps in comparison to the (lower-priced) sodium methoxide (here potassium salts of the fatty acids from the triglycerides) and higher yields are obtained with potassium methoxide. The optimum conditions for biodiesel production from canola oil are reported as being 1.59% by weight of potassium methoxide, a reaction temperature of 50 °C and a methanol/oil ratio of 4.5: 1. The biodiesel yield is 95.8% with a fatty acid content of 0.75% by weight.[10]

Literature

- N.Y. Turova; E.P. Turevskaya; V.G. Kessler; M.I. Yanovskaya, eds. (2002), The Chemistry of Metal Alkoxides, Springer US, doi:10.1007/b113856, ISBN 978-0-7923-7521-0

See also

References

- A.R. Ronzio; W.B. Cook. "4-Amino-2,6-dimethylpyrimidine". Organic Syntheses. 24. doi:10.15227/orgsyn.024.0006.

- Chimtek Engineering: Potassium Methylate Production Technology, retrieved 12 August 2015.

- J. Ruwwe (2008), "Metal alkoxides as catalysts for the biodiesel production" (PDF), Chim. Oggi Chem. Today, vol. 26, no. 1, pp. 26–28

- EP 2656905, M. Horn, B. Helpap, M. Thiel, M. Neumann, "Entquickung von Lösungen durch Ultrafiltration", published 2013-10-30, assigned to Evonik Degussa GmbH

- ICF International: Study on EU Implementation of the Minamata Convention on Mercury, retrieved 12 August 2015.

- Evonik Industries, GPS Safety Summary, Potassium Methylate, retrieved 12 August 2015.

- B.N. Pattanaik (2013), "The advances in processes and catalysts for the production of methyl formate by methanol carbonylation – a review", IJCPT, vol. 3, no. 2, pp. 55–70, ISSN 2277-4807

- US 20140148614, D. Schneider, K.-D. Mohl, M. Schäfer, J. Paschold, J.H. Teles, S. Rittinger, "Process for preparing methyl formate by reaction of methanol with carbon monoxide in the presence of a catalyst system comprising alkali metal formate and alkali metal alkoxide", published 2014-05-29, assigned to BASF SE

- G. Knothe; J. Krahl; J. Van Gerpen, eds. (2010), The Biodiesel Handbook (2nd ed.), AOCS Press, ISBN 978-1-893997-62-2

- A. Singh; B. He; J. Thompson; J. Van Gerpen (2006), "Process optimization of biodiesel production using alkaline catalysts" (PDF), Appl. Eng. Agric., vol. 22, no. 4, pp. 597–600, archived from the original (PDF) on 2015-11-23, retrieved 2017-02-13