SpaceX Raptor

The Raptor is a family of full-flow staged-combustion-cycle rocket engines developed and manufactured by SpaceX for use on the SpaceX Starship. The engine is powered by cryogenic liquid methane and liquid oxygen ("methalox"), as opposed to the RP-1 and liquid oxygen ("kerolox") combination used in SpaceX's earlier Merlin and Kestrel rocket engines. The Raptor engine has about triple the thrust of SpaceX's Merlin 1D engine, which powers the Falcon 9 and Falcon Heavy launch vehicles.

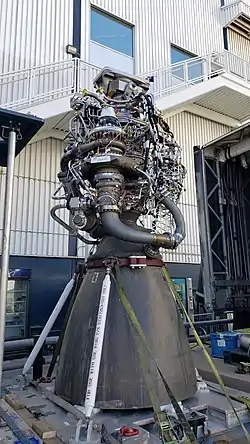

A Raptor 1 rocket engine ready for transport outside SpaceX's factory in Hawthorne, California | |

| Country of origin | United States |

|---|---|

| Manufacturer | SpaceX |

| Status | Currently in use |

| Liquid-fuel engine | |

| Propellant | LOX / CH4 |

| Mixture ratio | 3.6 (78% O2, 22% CH4)[1][2] |

| Cycle | Full-flow staged combustion |

| Pumps | 2 turbopumps |

| Configuration | |

| Chamber | 1 |

| Nozzle ratio | |

| Performance | |

| Thrust | Raptor 1: 185 tf (1.81 MN; 410,000 lbf)[5] Raptor 2: Raptor 3: 269 tf (2.64 MN; 590,000 lbf) |

| Throttle range | 40–100%[8] |

| Thrust-to-weight ratio | 143.8, sea-level |

| Chamber pressure |

|

| Specific impulse, vacuum | 363 s (3.56 km/s)[10] |

| Specific impulse, sea-level | 327 s (3.21 km/s)[9] |

| Mass flow | |

| Burn time | N/A |

| Dimensions | |

| Length | 3.1 m (10 ft)[13] |

| Diameter | 1.3 m (4 ft 3 in)[14] |

| Dry weight | 1,600 kg (3,500 lb)[6] |

| Used in | |

| SpaceX Starship | |

SpaceX's Starship system uses Raptor engines in its super-heavy-lift Super Heavy booster and in the Starship spacecraft, which is to act as the second stage when launched from Earth and as an independent spacecraft in LEO and beyond.[15] Starship is currently planned to be used for lifting satellites to Earth orbit, including additions to SpaceX's Starlink satellite constellation; for Moon landings, and in the exploration and colonization of Mars.[16] Unlike previous reusable rocket engines such as the RS-25, the engines are designed to be reused many times with little maintenance. [17]

Raptor is notable for being only the third rocket engine in history to be designed to use a full-flow staged-combustion-cycle, and the first of its kind to actually power a vehicle.[18]

The use of liquid methane/oxygen fuel, such as in the Raptor engine, is being used by many different companies in the 21st century, such as Blue Origin with its BE-4 engine, as well as the Longyun-70 engine being developed by Chinese startup Space Epoch for a rocket that has been described as a ‘mini Starship’ due to its similarities to the SpaceX Starship.[19] There is also the Zhuque-2 rocket of LandSpace, which in July 2023 was the first methane fueled launch vehicle to reach orbit.

Design

Full-Flow staged combustion

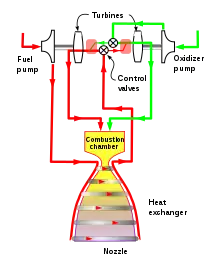

The Raptor engine is powered by subcooled liquid methane, and subcooled liquid oxygen in a full-flow staged combustion cycle. This is a departure from the simpler "open-cycle" gas generator system and LOX/kerosene propellants that the current Merlin engines use.[20] Also, the RS-25 engines (which were first used on the Space Shuttle) use a simpler form of a staged combustion cycle,[21] as do several Russian rocket engines, including the RD-180[20] and the RD-191.[22] This design allows the engine to achieve greater efficiency by using all of the available fuel without wasting any of it to power its turbo pumps.[18] An oxygen-rich turbine will power an oxygen turbopump, and fuel-rich turbine will power a methane turbopump. Both streams—oxidizer and fuel—will be mixed completely in the gas phase before they enter the combustion chamber.[18]

Before 2014, only two full-flow staged-combustion rocket engine designs had ever progressed sufficiently to be tested on test stands: the Soviet RD-270 project in the 1960s and the Aerojet Rocketdyne Integrated Powerhead Demonstrator in the mid-2000s.[23][22][24] The flight engine is designed for extreme reliability, aiming to support the airline-level of safety required by the point-to-point Earth transportation market.[25] Raptor has been claimed to be able to deliver "long life ... and more benign turbine environments".[26][22]

Engine ignition for all Raptor engines, both on the pad and in flight, was handled by dual-redundant spark-plug lit torch igniters,[27] eliminating the need for a dedicated, consumable igniter fluid, as used on Merlin.[22] This was changed for Raptor 2 engines where the lit torches were replaced by a secret ignition method that is allegedly less complex, lighter, cheaper and more reliable. Torch igniters are still used in oxygen and power heads.[28]

Propellants

The Raptor engine is designed for the use of deep cryogenic propellants—fluids cooled to near their freezing points, rather than using the cryo-propellants at their boiling points as it is more typical for cryogenic rocket engines.[29] The use of subcooled propellants increases propellant density to allow more propellant mass to be stored within the vehicle's tanks.[30] Engine performance is also increased with subcooled propellants. Specific impulse is increased, and the risk of cavitation at inputs to the turbopumps is reduced due to the higher propellant fuel mass flow rate per unit of power generated.[22] The oxidizer to fuel ratio of the engine would be approximately 3.8 to 1, as stated by Elon Musk.[31]

Performance

Musk revealed that their target performance for Raptor was a vacuum specific impulse of 382 s (3,750 m/s), with a thrust of 3 MN (670,000 lbf), a chamber pressure of 300 bar (30 MPa; 4,400 psi), and an expansion ratio of 150 for the vacuum-optimized variant.

Manufacturing and materials

Many components of early Raptor prototypes were manufactured using 3D printing, including turbopumps and injectors, with the effect of increasing the speed of development and iterative testing.[29] The 2016 subscale development engine had 40% (by mass) of its parts manufactured by 3D printing.[22] In 2019, engine manifolds were cast from SpaceX's in-house developed SX300 Inconel superalloy, soon to be changed to SX500.[32] The Raptor engine uses a large number of coaxial swirl injectors to admit propellants to the combustion chamber, rather than pintle injectors used on the previous Merlin rocket engines that SpaceX mass-produced for its Falcon family of launch vehicles.[33]

History

Conception and initial designs

An advanced rocket engine design project named Raptor, burning hydrogen and oxygen propellants, was first publicly discussed by SpaceX's Max Vozoff at the American Institute of Aeronautics and Astronautics Commercial Crew/Cargo symposium in 2009.[34] SpaceX had a few staff working on the Raptor upper-stage engine, then still a LH2/LOX concept, at a low level of priority.[35] Further mention of the development program occurred in 2011.[36] In March 2012, news accounts asserted that the Raptor upper-stage engine development program was underway, but details about it were not yet being publicly released.[37]

In October 2012, SpaceX publicly announced concept work on a rocket engine that would be "several times as powerful as the Merlin 1 series of engines, and won't use Merlin's RP-1 fuel", but declined to specify which fuel would be used.[38] They indicated that details on a new SpaceX rocket would be forthcoming in "one to three years" and that the large engine was intended for the next-generation launch vehicle using multiple of these large engines, that would be expected to launch payload masses of the order of 150 to 200 tonnes (150,000 to 200,000 kg; 330,000 to 440,000 lb) to low Earth orbit, exceeding the payload mass capability of the NASA Space Launch System by a wide margin.[38]

Development

In November 2012, Musk announced a new direction for the propulsion division of SpaceX which was towards developing methane-fueled rocket engines.[39] He further indicated that the Raptor concept would become a methane-based design[39] and that methane would be the fuel of choice for SpaceX's plans for Mars colonization.[24] Because of the presence of water underground and carbon dioxide in the atmosphere of Mars, methane, a simple hydrocarbon, can easily be synthesized on Mars using the Sabatier reaction.[40] In-situ resource production on Mars has been examined by NASA and found to be viable for oxygen, water, and methane production.[41]

When first mentioned by SpaceX in 2009, the term "Raptor" was applied exclusively to an upper-stage engine concept[34]—and 2012 pronouncements indicated that it was then still a concept for an upper stage engine[20]—but in early 2014 SpaceX confirmed that Raptor would be used both on a new second stage, as well as for the large (then, nominally a 10-meter-diameter) core of the Mars Colonial Transporter[24] (subsequently, in 2016, on both stages of the Interplanetary Transport System[42] and then, in 2017 on the Big Falcon Rocket).[43]

Public information released in November 2012 indicated that SpaceX might have a family of Raptor-designated rocket engines in mind;[44] this was confirmed by SpaceX in October 2013.[16] However, in March 2014 SpaceX COO Gwynne Shotwell clarified that the focus of the new engine development program is exclusively on the full-size Raptor engine; smaller subscale methalox engines were not planned on the development path to the very large Raptor engine.[45]

In October 2013, SpaceX announced that they would be performing methane engine tests of Raptor engine components at NASA's John C. Stennis Space Center and that SpaceX would add equipment to the existing test stand infrastructure to support liquid methane and hot gaseous methane engine component testing.[46][47][48] In April 2014, SpaceX completed the requisite upgrades and maintenance to the Stennis test stand to prepare for testing of Raptor components,[49] and the engine component testing program began in earnest, focusing on the development of robust startup and shutdown procedures. Component testing at Stennis also allowed hardware characterization and verification.[22]

SpaceX successfully began development testing of injectors in 2014 and completed a full-power test of a full-scale oxygen preburner in 2015. 76 hot-fire tests of the preburner, totaling some 400 seconds of test time, were executed from April–August 2015.[50] SpaceX completed its planned testing using NASA Stennis facilities in 2014 and 2015.[51]

In January 2016, the US Air Force awarded a US$33.6 million development contract to SpaceX to develop a prototype version of its methane-fueled reusable Raptor engine for use on the upper stage of the Falcon 9 and Falcon Heavy launch vehicles. Work under the contract was expected to be completed in 2018, with engine performance testing to be done at Stennis Space Center and at Los Angeles Air Force Base, California.[52][53]

Testing

.jpg.webp)

Initial development testing[50] of Raptor methane engine components was done at NASA's Stennis Space Center, where SpaceX added equipment to the existing infrastructure to support liquid methane engine testing.[16][48]The development Raptor engine discussed in the October 2013 time frame relative to Stennis testing was designed to generate more than 2,900 kN (661,000 lbf) vacuum thrust.[16] Raptor engine component testing began in May 2014 at the E-2 test complex which SpaceX modified to support methane engine tests.[16][49]

By early 2016, SpaceX had constructed a new engine test stand at their McGregor test site in central Texas for Raptor testing.[22][16] By August 2016, the first integrated Raptor rocket engine, manufactured at the SpaceX Hawthorne facility in California, was shipped to SpaceX McGregor for development testing.[54] The engine had 1 MN (220,000 lbf) thrust, less than half the thrust of the full-scale Raptor engine used for flight tests in 2019.[55] It is the first full-flow staged-combustion methalox engine ever to reach a test stand.[22]

On 26 September 2016, Elon Musk disclosed that the engine used multi-stage turbopumps. Substantial additional technical details of the ITS propulsion were summarized in an article on the Raptor engine published the next week.[22] In addition, a much smaller subscale development engine had already been built for design validation. At that time, this first subscale Raptor development engine had recently been tested on a ground test stand in McGregor, but for only one brief firing.[22] The Raptor subscale development engine produced approximately 1,000 kN (220,000 lbf) thrust.[22] To eliminate flow separation problems while being tested in Earth's atmosphere, the test nozzle expansion ratio had been limited to 150. NASASpaceFlight reported that the development engine was only one-third the size of any of the several larger engine designs that were discussed for the later flight vehicles.[22]

The first version of the flight engine is intended to operate at a chamber pressure of 250 bars (25 MPa; 3,600 psi), with the intent to raise it to 300 bars (30 MPa; 4,400 psi) at a later time.[56] By September 2017, the 200 bars (20 MPa; 2,900 psi) sub-scale test engine, with a thrust of 1 meganewton (220,000 lbf) and "a new alloy to help its oxygen-rich turbopump resist oxidization, ... had completed 1200 seconds of firings across 42 tests."[57] This alloy is known as SX500, created by the SpaceX metallurgy team which is used to contain hot oxygen gas in the engine at up to 12000 psi.[58]

Starship

Original configuration

-2018_version.png.webp)

In November 2016, the Raptor engine was projected to power the proposed Interplanetary Transport System (ITS), no earlier than the early 2020s.[22] Elon Musk discussed two engines: a sea-level variant (expansion ratio 40:1) for the first stage or ITS booster and a vacuum variant (expansion ratio 200:1) to obtain higher performance with the second stage. 42 of these sea-level engines were envisioned in the high-level design of the first stage, with a thrust per engine of 3,050 kN (690,000 lbf) at sea level and 3,285 kN (738,000 lbf) in the vacuum.[22] In addition, three gimbaled sea-level Raptor engines would be used for performing landings of the ITS second stage on Earth and Mars. Six vacuum-optimized Raptor engines, providing 3,500 kN (790,000 lbf) of thrust each, would also be used on the ITS second stage, for a total of nine engines.[59] The higher-efficiency Raptor Vacuum engines for in-space conditions were envisioned then to target a specific impulse of 382 s (3,750 m/s), using a much larger nozzle giving an expansion ratio of 200.[60] Six of these non-gimbaled engines were planned to provide primary propulsion for the 2016 designs of the ITS second stage.[22]

A year later, at the 68th IAC in September 2017, and following a year of development by the propulsion team, Musk said that a smaller Raptor engine—with slightly over half as much thrust as the previous concept designs for the ITS — would be used on the next-generation rocket, a 9 m (30 ft)-diameter launch vehicle and publicly referred to as Big Falcon Rocket (BFR) and later renamed Starship.[61] The redesign was aimed at making the new system useful for substantial Earth-orbit and cislunar launches so that the new system might pay for itself, in part, through economic spaceflight activities in the near-Earth space zone.[62] With the much smaller launch vehicle, fewer Raptor engines would be used on each stage. BFR was then slated to have 31 Raptors on the first stage and 6 on the second stage.[63][22] By mid-2018, SpaceX was publicly stating that the sea-level flight version Raptor engine design, with a nozzle exit diameter of 1.3 m (4.3 ft), was expected to have 1,700 kN (380,000 lbf) thrust at sea level with a specific impulse of 330 s (3,200 m/s) increasing to a specific impulse of 356 s (3,490 m/s) in vacuum.[57] The vacuum flight version, with a nozzle exit diameter of 2.4 m (7.9 ft), was expected to exert 1,900 kN (430,000 lbf) force with a specific impulse of 375 s (3,680 m/s).[57] The earliest versions of the flight engine are designed to operate at 250 bars (25,000 kPa; 3,600 psi) chamber pressure; but SpaceX is expected to increase this to 300 bar (30,000 kPa; 4,400 psi) in later iterations.[57]

In the BFR update given in September 2018, Musk showed a video of a 71-second fire test of a Raptor engine, and stated that "this is the Raptor engine that will power BFR, both the ship and the booster; it's the same engine. [...] approximately a 200 (metric) tons engine aiming for roughly 300 bar chamber pressure. [...] If you had it at a high expansion ratio, has the potential to have a specific impulse of 380."[9]

Final engine configuration

Thirty-three sea-level variant Raptor engines will power the Super Heavy booster, while the Starship spacecraft contains six Raptor engines, three optimized for sea‑level and three optimized for vacuum.[64] The bottom-most section, informally called the "skirt", houses the Raptor engines, as well as composite overwrapped pressure vessels that store helium gas used to spin up the Raptor turbopumps.[65] Above that section are the liquid oxygen and liquid methane propellant tanks, separated by a "common dome" containing a small, spherical methane "header tank" used to contain propellant for landing.[66][67] Six Raptor engines power the spacecraft, three designed for sea-level operation and three Raptor Vacuum engines optimized for use in the vacuum of space, producing a cumulative thrust of about 14 MN (1,400 tf; 3,100,000 lbf).[7]

Proposed Falcon 9 upper stage

In January 2016, the United States Air Force (USAF) awarded a US$33.6 million development contract to SpaceX to develop a prototype version of its methane-fueled reusable Raptor engine for use on the upper stage of the Falcon 9 and Falcon Heavy launch vehicles. The contract required double-matching funding by SpaceX of at least US$67.3 million.[52][68] Work under the contract was expected to be completed no later than December 2018, and engine performance testing was planned to be completed at NASA's Stennis Space Center in Mississippi under US Air Force supervision.[52][53] The USAF contract called only for the development and build of a single prototype engine with a series of ground tests, with no upper-stage launch vehicle design funded by the contract.[52] The Air Force was working with the US Congress in February 2016 to pursue new launch systems.[69]

In October 2017 the US Air Force (USAF) awarded a US$40.8 million modification for the development of the Raptor engine prototype for the Evolved Expendable Launch Vehicle program, with work under that contract expected to be completed by April 2018.[70]

As a DoD military project, little technical detail was ever publicly released about the USAF second stage engine or the results of the prototype build and test program. The prototype however was to be designed to serve the theoretical purpose of servicing an upper stage that could be used on the existing Falcon 9 and Falcon Heavy launch vehicles, with liquid methane and liquid oxygen, propellants, a full-flow staged combustion cycle, and explicitly to be a reusable engine.[53]

Production

In July 2021, SpaceX announced that they would be building a second production facility for Raptor engines, this one in south Texas near the existing rocket engine test facility. Dallas Morning News reported in July that SpaceX will "break ground soon" and that the facility will concentrate on the serial production of Raptor 2, while the California facility will produce Raptor Vacuum and new/experimental Raptor designs. The new facility is expected to eventually produce 800 to 1000 rocket engines each year.[71][72] SpaceX aims at a lifetime of 1000 flights for Raptor.[73] In 2019 the (marginal) cost of the engine was stated to be approaching $1 million. SpaceX plans to mass-produce up to 500 Raptor engines per year, each costing less than $250,000. Each Starship booster will use 33 sea-level Raptors, while each Starship spacecraft will use 3 sea-level Raptors plus 3 Vacuum-optimized Raptors.

By late 2021, SpaceX said that scaling Raptor production to support the frequent Starship test program planned for 2022 was "currently the biggest constraint on how many vehicles we can make" and that failing to achieve a flight rate of at least once every two weeks by late 2022 would open up the possibility of bankruptcy for SpaceX. The reason given was that Starship orbital launch capability is necessary to deliver the next generation Starlink satellites needed to operationalize the massively capital-intensive Starlink broadband internet constellation.[74]

Versions

Raptor Vacuum

.jpg.webp)

Raptor Vacuum[75] (RVac) is a variant of Raptor with an extended, regeneratively-cooled nozzle for higher specific impulse in the vacuum of space. The vacuum-optimized Raptor engine is aiming for a specific impulse of ~380 s (3,700 m/s).[76] A full-duration test of version 1 of the Raptor Vacuum engine was completed in September 2020 at the SpaceX development facility in McGregor, Texas.[75] The first three operational Raptor Vacuum engines were slated to fly on SpaceX Starship prototype S20 and were installed on 4 August 2021.[77] However, SN20 was retired before it flew.

Raptor 2

Raptor 2 is a complete redesign of the Raptor 1 engine.[78] The turbomachinery, chamber, nozzle, and electronics were all redesigned, and many flanges were converted to welds, while other parts were simply removed.[79] Raptor 2 engines have had further simplifications made during their production run.

In September 2019, SpaceX stated their "current plan" was to use Raptor 2 for the three "sea-level" engines on the Starship second-stage and also for all booster engines — both those that gimbal and those that do not — on the Super Heavy first stage.[80]These engines are currently being produced at SpaceX's engine development facility near McGregor, Texas. On 18 December 2021, Elon Musk announced on his Twitter account that Raptor 2 started production, and it will have over 230 tons of force. [81] In a Starship update on 10 February 2022, Musk showed the capabilities of Raptor 2 and how it is simplified but more powerful than the original Raptor.[79] [82]

Raptor 2 engines were achieving 230 tf (510,000 lbf) of thrust consistently by February 2022, although SpaceX expects to be able to tune engine parameters and design over time to achieve at least 250 tf (550,000 lbf). Moreover, Musk indicated that the engine production cost was approximately half that of the Raptor 1 version SpaceX had been using in 2018–2021.[79] In June 2022, Musk tweeted that 250 tons was achievable.[83]

Production rate for Raptor 2 had reached five per week by February 2022.[79]

SpaceX has completed many static fire tests on a vehicle using Raptor 2s, including a 31 engine test (intended to be 33) on 9 February 2023.

SpaceX completed the Integrated Flight Test on 20 April 2023. The Super Heavy had 33 Raptor 2 engines during the launch but 3 of those had already failed by the time the rocket started to lift from the launchpad. The mission ended after 4 minute flight after climbing to apogee of ~39 km over the Gulf of Mexico. The vehicle experienced multiple engines out during the flight test, lost altitude, and began to tumble. The flight termination system was commanded on both the booster and ship.[84]

Raptor 3

In May 2023, Musk reported a successful static fire of Raptor 3 to 350 bar (5,100 psi) for 45 seconds, producing 269 tons of thrust.[85]

Comparison to other engines

| Engine | Rockets | Thrust | Specific impulse,

vacuum |

Thrust-to-

weight ratio |

Propellant | Cycle |

|---|---|---|---|---|---|---|

| Raptor sea-level | Starship | 2,400 kN (540,000 lbf)[55] | ~350 s (3,400 m/s)[86] | 200 (goal) | LCH4 / LOX | Full-flow staged combustion |

| Raptor vacuum | ~380 s (3,700 m/s)[86] | <120 | ||||

| Merlin 1D sea-level | Falcon booster stage | 914 kN (205,000 lbf) | 311 s (3,050 m/s)[87] | 176[88] | RP-1 / LOX | Gas generator |

| Merlin 1D vacuum | Falcon upper stage | 934 kN (210,000 lbf)[89] | 348 s (3,410 m/s)[89] | 180[88] | ||

| Blue Origin BE-4 | New Glenn, Vulcan | 2,400 kN (550,000 lbf)[90] | 339 s (3,320 m/s)[91] | LCH4 / LOX | Oxidizer-rich staged combustion | |

| Energomash RD-170/171M | Energia, Zenit, Soyuz-5 | 7,904 kN (1,777,000 lbf)[92] | 337.2 s (3,307 m/s)[92] | 79.57[92] | RP-1 / LOX | |

| Energomash RD-180 | Atlas III, Atlas V | 4,152 kN (933,000 lbf)[93] | 338 s (3,310 m/s)[93] | 78.44[93] | ||

| Energomash RD-191/181 | Angara, Antares | 2,090 kN (470,000 lbf)[94] | 337.5 s (3,310 m/s)[94] | 89[94] | ||

| Kuznetsov NK-33 | N1, Soyuz-2-1v | 1,638 kN (368,000 lbf)[95] | 331 s (3,250 m/s)[95] | 136.66[95] | ||

| Energomash RD-275M | Proton-M | 1,832 kN (412,000 lbf) | 315.8 s (3,097 m/s) | 174.5 | N2O4 / UDMH | |

| Rocketdyne RS-25 | Space Shuttle, SLS | 2,280 kN (510,000 lbf) | 453 s (4,440 m/s)[96] | 73[97] | LH2 / LOX | Fuel-rich staged combustion |

| Aerojet Rocketdyne RS-68A | Delta IV | 3,560 kN (800,000 lbf) | 414 s (4,060 m/s) | 51[98] | LH2 / LOX | Gas generator |

| Rocketdyne F-1 | Saturn V | 7,740 kN (1,740,000 lbf) | 304 s (2,980 m/s)[99] | 83 | RP-1 / LOX | Gas generator |

See also

References

- Sierra Engineering & Software, Inc. (18 June 2019). "Exhaust Plume Calculations for SpaceX Raptor Booster Engine" (PDF). p. 1. Retrieved 17 September 2021.

The nominal operating condition for the Raptor engine is an injector face stagnation pressure (Pc) of 3669.5 psia and a somewhat fuel-rich engine O/F mixture ratio (MR) of 3.60. The current analysis was performed for the 100% nominal engine operating pressure (Pc=3669.5 psia) and an engine MR of 3.60.

- Space Exploration Technologies Corp. (17 September 2021). "Draft Programmatic Environmental Assessment for the SpaceX Starship/Super Heavy Launch Vehicle Program at the SpaceX Boca Chica Launch Site in Cameron County, Texas" (PDF). faa.gov. FAA Office of Commercial Space Transportation. p. 12. Archived (PDF) from the original on 17 September 2021. Retrieved 17 September 2021.

Super Heavy is expected to be equipped with up to 37 Raptor engines, and Starship will employ up to six Raptor engines. The Raptor engine is powered by liquid oxygen (LOX) and liquid methane (LCH4) in a 3.6:1 mass ratio, respectively.

- Sierra Engineering & Software, Inc. (18 June 2019). "Exhaust Plume Calculations for SpaceX Raptor Booster Engine" (PDF). p. 1. Retrieved 17 September 2021.

The subject engine uses a closed power cycle with a 34.34:1 regeneratively-cooled thrust chamber nozzle.

- "Starbase Tour with Elon Musk [PART 2]" on YouTube by Everyday Astronaut, 7 August 2021

- Bergin, Chris (23 January 2022). "Raptor 2 testing at full throttle on the SpaceX McGregor test stands". NASASpaceFlight.com. Retrieved 22 March 2022.

- Tim Dodd (14 July 2022). "Raptor 1 VS Raptor 2: What's New // What's Different". YouTube.

- "Starship : Official SpaceX Starship Page". SpaceX. Archived from the original on 22 May 2020. Retrieved 24 May 2020.

- @elonmusk (17 August 2020). "Max demonstrated Raptor thrust is ~225 tons & min is ~90 tons, so they're actually quite similar. Both Merlin & Raptor could throttle way lower with added design complexity" (Tweet) – via Twitter.

- Musk, Elon (17 September 2018). "First Lunar BFR Mission". YouTube. Event occurs at 45:30. Archived from the original on 11 February 2020. Retrieved 19 September 2018.

And this is the Raptor engine that will power BFR both the ship and the booster, it's the same engine. And this is approximately a 200-ton thrust engine that's aiming for roughly a 300-bar or 300-atmosphere chamber pressure. And if you have it at a high expansion ratio it has the potential to have a specific impulse of 380.

- Alejandro G. Belluscio (7 March 2014). "SpaceX advances drive for Mars rocket via Raptor power". NASASpaceFlight.com. Retrieved 27 December 2021.

- At 2.23 MN thrust and 350 s specific impulse

- 78% O2, 22% CH4 mixture ratio

- "Starship | SpaceX". Archived from the original on 30 September 2019. Retrieved 2 October 2019.

- Musk, Elon (29 September 2017). "Making Life Multiplanetary". youtube.com. SpaceX. Archived from the original on 18 March 2021. Retrieved 29 September 2017.

- "Starship Users Guide, Revision 1.0, March 2020" (PDF). SpaceX/files. SpaceX. March 2020. Archived from the original (PDF) on 2 April 2020. Retrieved 18 May 2020.

SpaceX's Starship system represents a fully reusable transportation system designed to service Earth orbit needs as well as missions to the Moon and Mars. This two-stage vehicle — composed of the Super Heavy rocket (booster) and Starship (spacecraft)

- Leone, Dan (25 October 2013). "SpaceX Could Begin Testing Methane-fueled Engine at Stennis Next Year". Space News. Archived from the original on 25 October 2013. Retrieved 26 October 2013.

- "The rockets NASA and SpaceX plan to send to the moon".

- Dodd, Tim (25 May 2019). "Is SpaceX's Raptor engine the king of rocket engines?". Everyday Astronaut. Retrieved 22 May 2023.

- Jones, Andrew. "Chinese startups conduct hot fire tests for mini version of SpaceX's Starship".

- Todd, David (22 November 2012). "SpaceX's Mars rocket to be methane-fuelled". Flightglobal. Archived from the original on 30 October 2013. Retrieved 5 December 2012.

Musk said Lox and methane would be SpaceX's propellants of choice on a mission to Mars, which has long been his stated goal. SpaceX's initial work will be to build a Lox/methane rocket for a future upper stage, codenamed Raptor. The design of this engine would be a departure from the "open cycle" gas generator system that the current Merlin 1 engine series uses. Instead, the new rocket engine would use a much more efficient "staged combustion" cycle that many Russian rocket engines use.

- "Space Shuttle Main Engines". NASA. Archived from the original on 10 December 2015. Retrieved 6 March 2013.

- Belluscio, Alejandro G. (3 October 2016). "ITS Propulsion – The evolution of the SpaceX Raptor engine". NASASpaceFlight.com. Archived from the original on 26 January 2021. Retrieved 3 October 2016.

- Nardi, Tom (13 February 2019). "The "impossible" tech behind SpaceX's new engine". Hackaday. Archived from the original on 4 February 2021. Retrieved 15 February 2019.

- Belluscio, Alejandro G. (7 March 2014). "SpaceX advances drive for Mars rocket via Raptor power". NASAspaceflight.com. Archived from the original on 11 September 2015. Retrieved 7 March 2014.

- Foust, Jeff (15 October 2017). "Musk offers more technical details on BFR system". SpaceNews. Archived from the original on 7 March 2021. Retrieved 15 October 2017.

[initial flight testing will be with] a full-scale ship doing short hops of a few hundred kilometers altitude and lateral distance ... fairly easy on the vehicle, as no heat shield is needed, we can have a large amount of reserve propellant and don't need the high area ratio, deep space Raptor engines. ... 'The engine thrust dropped roughly in proportion to the vehicle mass reduction from the first IAC talk,' Musk wrote when asked about that reduction in thrust. The reduction in thrust also allows for the use of multiple engines, giving the vehicle an engine-out capability for landings. ... Musk was optimistic about scaling up the Raptor engine from its current developmental model to the full-scale one. 'Thrust scaling is the easy part. Very simple to scale the dev Raptor to 170 tons,' he wrote. 'The flight engine design is much lighter and tighter, and is extremely focused on reliability.' He added the goal is to achieve 'passenger airline levels of safety' with the engine, required if the vehicle is to serve point-to-point transportation markets.

- Shotwell, Gwynne (17 March 2015). "Statement of Gwynne Shotwell, President & Chief Operating Officer, Space Exploration Technologies Corp. (SpaceX)" (PDF). Congressional testimony. US House of Representatives, Committee on Armed Service Subcommittee on Strategic Forces. pp. 14–15. Archived (PDF) from the original on 28 January 2016. Retrieved 11 January 2016.

SpaceX has already begun self-funded development and testing on our next-generation Raptor engine. ... Raptor development ... will not require external development funds related to this engine.

- Ralph, Eric (27 August 2019). "SpaceX scrubs Starhopper's final Raptor-powered flight as Elon Musk talks 'finicky' igniters". Teslarati. Archived from the original on 2 December 2019. Retrieved 27 August 2019.

Raptor uses those spark plugs to ignite its ignition sources [forming] full-up blow torches ... —likely miniature rocket engines using the same methane and oxygen fuel as Raptor—then ignite the engine's methane and oxygen preburners before finally igniting those mixed, high-pressure gases in the combustion chamber.

- Astronaut, Everyday (9 July 2022). "Elon Musk Explains SpaceX's Raptor Engine!" (video). youtube.com. Everyday Astronaut.

- Elon Musk, Mike Suffradini (7 July 2015). Elon Musk comments on Falcon 9 explosion – Huge Blow for SpaceX (video). Event occurs at 39:25–40:45. Archived from the original on 6 September 2015. Retrieved 30 December 2015.

- "The "super chill" reason SpaceX keeps aborting launches". Quartz. 29 February 2016. Retrieved 22 May 2023.

- How (and Why) SpaceX Will Colonize Mars Archived 17 August 2015 at the Wayback Machine, accessed 19 August 2015. Musk: "The critical elements of the solution are rocket reusability and low cost propellant (CH4 and O2 at an O/F ratio of ~3.8). And, of course, making the return propellant on Mars, which has a handy CO2 atmosphere and lots of H2O frozen in the soil."

- "SpaceX Casting Raptor Engine Parts from Supersteel Alloys Feb 2019". Archived from the original on 26 October 2020. Retrieved 22 October 2020.

- Characteristics of Gas-Centered Swirl-Coaxial Injector with Liquid Flow Excitation, AIAA, 25 February 2019, accessed 8 June 2019.

- "Long term SpaceX vehicle plans". HobbySpace.com. 7 July 2009. Archived from the original on 14 February 2010. Retrieved 13 July 2009.

- "Notes: Space Access'11: Thurs. – Afternoon session – Part 2: SpaceX". RLV and Space Transport News. 7 April 2011. Archived from the original on 20 March 2012. Retrieved 8 April 2011.

- "SpaceX Raptor LH2/LOX engine". RLV and Space Transport News. 8 August 2011. Archived from the original on 2 November 2011. Retrieved 9 August 2011.

- Rosenberg, Zach (16 March 2012). "SpaceX readies upgraded engines". Flightglobal. Archived from the original on 5 March 2014. Retrieved 17 March 2012.

SpaceX is in the midst of a variety of ambitious engine programmes, including the Merlin 2, a significant modification of the Merlin 1 series, and the Raptor upper stage engine. Details of both projects are tightly held.

- Rosenberg, Zach (15 October 2012). "SpaceX aims big with massive new rocket". Flightglobal. Archived from the original on 18 October 2012. Retrieved 17 October 2012.

- Todd, David (20 November 2012). "Musk goes for methane-burning reusable rockets as step to colonise Mars". FlightGlobal Hyperbola. Archived from the original on 11 June 2016. Retrieved 4 November 2015.

"We are going to do methane." Musk announced as he described his future plans for reusable launch vehicles including those designed to take astronauts to Mars within 15 years, "The energy cost of methane is the lowest and it has a slight Isp (Specific Impulse) advantage over Kerosene," said Musk adding, "And it does not have the pain in the ass factor that hydrogen has".

- GPUs to Mars: Full-Scale Simulation of SpaceX's Mars Rocket Engine. YouTube. 5 May 2015. Retrieved 4 June 2015.

- mmooney (8 November 2015). "In-Situ Resource Utilization – Mars Atmosphere/Gas Chemical Processing". NASA SBIR/STTR. NASA. Archived from the original on 18 June 2016. Retrieved 2 June 2015.

- Foust, Jeff (27 September 2016). "SpaceX's Mars plans call for massive 42-engine reusable rocket". SpaceNews. Retrieved 7 April 2018.

Musk stated it's possible that the first spaceship would be ready for tests in four years... 'We're kind of being intentionally fuzzy about the timeline,' he said. 'We're going to try and make as much progress as we can with a very constrained budget.'

- Foust, Jeff (15 October 2017). "Musk offers more technical details on BFR system". SpaceNews. Archived from the original on 7 March 2021. Retrieved 7 April 2018.

- Todd, David (20 November 2012). "Musk goes for methane-burning reusable rockets as step to colonise Mars". FlightGlobal Hyperbola. Archived from the original on 29 October 2013. Retrieved 22 November 2012.

The new Raptor upper stage engine is likely to be only the first engine in a series of lox/methane engines.

- Gwynne Shotwell (21 March 2014). Broadcast 2212: Special Edition, interview with Gwynne Shotwell (audio file). The Space Show. Event occurs at 21:25–22:10. 2212. Archived from the original (mp3) on 22 March 2014. Retrieved 22 March 2014.

our focus is the full Raptor size

- "Cochran: Space-X Decision Bodes Well for Job Growth in South Mississippi". Senator Cochran. 23 October 2013. Archived from the original on 4 March 2016. Retrieved 27 October 2013.

- "NASA Stennis Space Center to Test SpaceX Next Generation Rocket Engines Systems". Mississippi Development Authority. 23 October 2013. Archived from the original on 3 December 2013. Retrieved 27 October 2013.

- Messier, Doug (23 October 2013). "SpaceX to Conduct Raptor Engine Testing in Mississippi". Parabolic Arc. Archived from the original on 24 October 2013. Retrieved 23 October 2013.

- Guess, Natalie (21 April 2014). "NASA, SpaceX Cut Ribbon To Launch Testing Partnership". MS EIGS. Archived from the original on 8 July 2015. Retrieved 22 April 2014.

- "NASA-SpaceX testing partnership going strong" (PDF). Lagniappe, John C. Stennis Space Center. NASA. September 2015. Archived (PDF) from the original on 31 December 2015. Retrieved 10 January 2016.

this project is strictly private industry development for commercial use

- "Stennis set for busy 2016 test schedule" (PDF). Lagniappe. NASA-John C. Stennis Space Center. February 2016. p. 3. Archived (PDF) from the original on 26 July 2019. Retrieved 2 March 2016.

After completing successful test series in 2014 and 2015 on components for the new Raptor rocket engine being developed by SpaceX, there also is hope for additional test agreements with the company.

- "Contracts: Air Force". U.S. Department of Defense (Press release). 13 January 2016. Archived from the original on 15 January 2016. Retrieved 15 January 2016.

- Gruss, Mike (13 January 2016). "Orbital ATK, SpaceX Win Air Force Propulsion Contracts". SpaceNews. Retrieved 15 January 2016.

- Berger, Eric (10 August 2016). "SpaceX has shipped its Mars engine to Texas for tests". Ars Technica. Archived from the original on 18 August 2016. Retrieved 17 August 2016.

- Elon Musk on Twitter: SN40 is about to be tested & has several upgrades over 330 bar engine. For reference, 330 bar on Raptor produces ~225 tons (half a million pounds) of force.

- Elon Musk speech: Becoming a Multiplanet Species Archived 9 March 2018 at the Wayback Machine, 29 September 2017, 68th annual meeting of the International Astronautical Congress in Adelaide, Australia

- Gaynor, Phillip (9 August 2018). "The Evolution of the Big Falcon Rocket". NASASpaceFlight.com. Archived from the original on 17 August 2018. Retrieved 17 August 2018.

- "SpaceX Casting Raptor Engine Parts from Supersteel Alloys | NextBigFuture.com". 18 February 2019. Retrieved 22 May 2023.

- Mike Wall (27 September 2016). "SpaceX's Elon Musk Unveils Interplanetary Spaceship to Colonize Mars". Space.com. Retrieved 22 May 2023.

- Musk, Elon (27 September 2016). "SpaceX IAC 2016 Announcement" (PDF). Mars Presentation. SpaceX. Archived from the original (PDF) on 28 September 2016. Retrieved 27 September 2016.

- Mike Wall (29 September 2017). "Elon Musk Wants Giant SpaceX Spaceship to Fly People to Mars by 2024". Space.com. Retrieved 22 May 2023.

- Elon Musk (19 July 2017). Elon Musk, ISS R&D Conference (video). ISS R&D Conference, Washington DC, USA. Event occurs at 49:48–51:35. Retrieved 21 September 2017.

the updated version of the Mars architecture: Because it has evolved quite a bit since that last talk. ... The key thing that I figured out is how do you pay for it? If we downsize the Mars vehicle, make it capable of doing Earth-orbit activity as well as Mars activity, maybe we can pay for it by using it for Earth-orbit activity. That is one of the key elements in the new architecture. It is similar to what was shown at IAC, but a little bit smaller. Still big, but this one has a shot at being real on the economic front.

- Foust, Jeff (29 September 2017). "Musk unveils revised version of giant interplanetary launch system". SpaceNews. Archived from the original on 8 October 2017. Retrieved 1 October 2017.

- September 2020, Mike Wall 25 (25 September 2020). "SpaceX fires up in-space version of Starship's Raptor engine for 1st time (video)". Space.com. Archived from the original on 21 August 2021. Retrieved 11 September 2021.

- Bergin, Chris (31 August 2021). "Starbase Launch Tower enters Mechazilla installation phase". NASASpaceFlight.com. Archived from the original on 8 September 2021. Retrieved 9 September 2021.

- Bergin, Chris (15 November 2020). "Starship SN8 hoping for speedy return to testing as additional vehicles line up". NASASpaceFlight.com. Archived from the original on 12 December 2020. Retrieved 10 September 2021.

- Musk, Elon (2 March 2020). "We're stripping SN2 to bare minimum to test the thrust puck to dome weld under pressure, first with water, then at cryo. Hopefully, ready to test in a few days". Twitter. Archived from the original on 27 April 2021. Retrieved 9 September 2021.

- "SpaceX, Orbital ATK + Blue Origin Signed On By SMC For Propulsion Prototypes". Satnews Daily. 13 January 2016. Archived from the original on 4 February 2021. Retrieved 7 February 2016.

- Harper, Jon (11 February 2016). "Air Force Outlines Future Space Launch Plans". National Defense. Retrieved 12 February 2016.

- "Contracts: Air Force". U.S. Department of Defense Contracts press release. 19 October 2017. Archived from the original on 7 February 2018. Retrieved 6 February 2018.

Space Exploration Technologies Corp., Hawthorne, California, has been awarded a $40,766,512 modification (P00007) for the development of the Raptor rocket propulsion system prototype for the Evolved Expendable Launch Vehicle program. Work will be performed at NASA Stennis Space Center, Mississippi; Hawthorne, California; McGregor, Texas; and Los Angeles Air Force Base, California; and is expected to be complete by April 30, 2018. Fiscal 2017 research, development, test and evaluation funds in the amount of $40,766,512 are being obligated at the time of award. The Launch Systems Enterprise Directorate, Space and Missile Systems Center, Los Angeles AFB, California, is the contracting activity (FA8811-16-9-0001).

- "Elon Musk says SpaceX's next Texas venture will be a rocket engine factory near Waco". Dallas Morning News. 10 July 2021. Archived from the original on 11 July 2021. Retrieved 11 July 2021.

- "We are breaking ground soon on a second Raptor factory at SpaceX Texas test site. This will focus on volume production of Raptor 2, while California factory will make Raptor Vacuum & new, experimental designs." Archived 10 July 2021 at the Wayback Machine, Elon Musk, 10 July 2021.

- O'Callaghan, Jonathan (31 July 2019). "The wild physics of Elon Musk's methane-guzzling super-rocket". WIRED. Archived from the original on 22 February 2021. Retrieved 5 September 2019.

- Foust, Jeff (1 December 2021). "SpaceX grapples with Raptor production problems". SpaceNews. Retrieved 7 December 2021.

- "Completed a full duration test fire of the Raptor Vacuum engine at SpaceX's rocket development facility in McGregor, Texas". SpaceX. 24 September 2020. Archived from the original on 18 November 2020. Retrieved 25 September 2020.

- "Sea level Raptor's vacuum Isp is ~350 sec, but ~380 sec with larger vacuum-optimized nozzle". Archived from the original on 25 September 2019. Retrieved 11 September 2019.

- "All 6 engines mounted to first orbital Starship including 3 RVac engines on SN20". Twitter. Archived from the original on 4 August 2021. Retrieved 4 August 2021.

- "Ship 20 prepares for Static Fire - New Raptor 2 factory rises". NASASpaceFlight.com. 11 October 2021. Retrieved 12 February 2022.

- Mooney, Justin; Bergin, Chris (11 February 2022). "Musk outlines Starship progress towards self-sustaining Mars city". NASASpaceFlight. Retrieved 12 February 2022.

- "All Raptors being the same, whether fixed or gimbaling". Twitter. Archived from the original on 12 July 2021. Retrieved 12 July 2021.

- @elonmusk (18 December 2021). "Each Raptor 1 engine above produces 185 metric tons of force. Raptor 2 just started production & will do 230+ tons or over half a million pounds of force" (Tweet). Retrieved 20 November 2022 – via Twitter.

- Starship Update, retrieved 12 February 2022

- "Elon Musk on Twitter: "@Rainmaker1973 250 tons of force is achievable"". Twitter. Retrieved 11 June 2022.

- "Starship Flight Test". SpaceX. Retrieved 28 April 2023.

- Elon Musk [@elonmusk] (12 May 2023). "Raptor V3 just achieved 350 bar chamber pressure (269 tons of thrust). Congrats to @SpaceX propulsion team! Starship Super Heavy Booster has 33 Raptors, so total thrust of 8877 tons or 19.5 million pounds" (Tweet) – via Twitter.

- "Sea level Raptor's vacuum Isp is ~350 sec, but ~380 sec with larger vacuum-optimized nozzle". Retrieved 11 September 2019.

- "Merlin 1C". Astronautix.com. Archived from the original on 11 April 2011. Retrieved 2 November 2013.

- Mueller, Thomas (8 June 2015). "Is SpaceX's Merlin 1D's thrust-to-weight ratio of 150+ believable?". Retrieved 9 July 2015.

- "SpaceX Falcon 9 product page". Retrieved 30 September 2016.

- Ferster, Warren (17 September 2014). "ULA To Invest in Blue Origin Engine as RD-180 Replacement". Space News. Archived from the original on 18 September 2014. Retrieved 19 September 2014.

- "RD-171b". Retrieved 13 May 2023.

- "RD-171M". NPO Energomash. Retrieved 30 June 2015.

- "RD-180". NPO Energomash. Retrieved 30 June 2015.

- "RD-191". NPO Energomash. Retrieved 7 April 2016.

- "NK-33". Astronautix.com. Archived from the original on 25 June 2002. Retrieved 1 April 2015.

- "SSME". Astronautix.com. Archived from the original on 28 December 2016. Retrieved 25 October 2021.

- "Encyclopedia Astronautica: SSME". Archived from the original on 28 December 2016. Retrieved 25 October 2021.

- "Encyclopedia Astronautica: RS-68". Archived from the original on 28 December 2016. Retrieved 25 October 2021.

- "F-1". Astronautix.com. Archived from the original on 9 November 2013. Retrieved 2 November 2013.

External links

- SpaceX Raptor Engine Test on 25 September 2016, SciNews, video, September 2016.

- GPUs to Mars: Full-scale Simulation of SpaceX's Mars Rocket Engine, Adam Lichtl and Steven Jones, GPU Technology Conference, spring 2015.

- unofficial raptor engine log infographic