Reptation

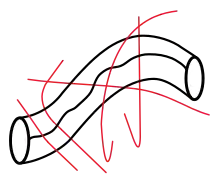

A peculiarity of thermal motion of very long linear macromolecules in entangled polymer melts or concentrated polymer solutions is reptation.[1] Derived from the word reptile, reptation suggests the movement of entangled polymer chains as being analogous to snakes slithering through one another.[2] Pierre-Gilles de Gennes introduced (and named) the concept of reptation into polymer physics in 1971 to explain the dependence of the mobility of a macromolecule on its length. Reptation is used as a mechanism to explain viscous flow in an amorphous polymer.[3][4] Sir Sam Edwards and Masao Doi later refined reptation theory.[5][6] Similar phenomena also occur in proteins.[7]

Two closely related concepts are reptons and entanglement. A repton is a mobile point residing in the cells of a lattice, connected by bonds.[8][9] Entanglement means the topological restriction of molecular motion by other chains.[10]

Theory and mechanism

Reptation theory describes the effect of polymer chain entanglements on the relationship between molecular mass and chain relaxation time. The theory predicts that, in entangled systems, the relaxation time τ is proportional to the cube of molecular mass, M: τ ~ M 3. The prediction of the theory can be arrived at by a relatively simple argument. First, each polymer chain is envisioned as occupying a tube of length L, through which it may move with snake-like motion (creating new sections of tube as it moves). Furthermore, if we consider a time scale comparable to τ, we may focus on the overall, global motion of the chain. Thus, we define the tube mobility as

- μtube= v/f,

where v is the velocity of the chain when it is pulled by a force, f. μ tube will be inversely proportional to the degree of polymerization (and thus also inversely proportional to chain weight).

The diffusivity of the chain through the tube may then be written as

- Dtube=kBT μtube.

By then recalling that in 1-dimension the mean squared displacement due to Brownian motion is given by

- s(t)2 = 2Dtube t,

we obtain

- s(t)2=2kBT μtube t.

The time necessary for a polymer chain to displace the length of its original tube is then

- t =L2/(2kBT μtube).

By noting that this time is comparable to the relaxation time, we establish that τ~L2/μtube. Since the length of the tube is proportional to the degree of polymerization, and μtube is inversely proportional to the degree of polymerization, we observe that τ~(DPn)3 (and so τ~M 3).

From the preceding analysis, we see that molecular mass has a very strong effect on relaxation time in entangled polymer systems. Indeed, this is significantly different from the untangled case, where relaxation time is observed to be proportional to molecular mass. This strong effect can be understood by recognizing that, as chain length increases, the number of tangles present will dramatically increase. These tangles serve to reduce chain mobility. The corresponding increase in relaxation time can result in viscoelastic behavior, which is often observed in polymer melts. Note that the polymer’s zero-shear viscosity gives an approximation of the actual observed dependency, τ ~ M 3.4;[11] this relaxation time has nothing to do with the reptation relaxation time.

Models

Entangled polymers are characterized with effective internal scale, commonly known as the length of macromolecule between adjacent entanglements .

Entanglements with other polymer chains restrict polymer chain motion to a thin virtual tube passing through the restrictions.[12] Without breaking polymer chains to allow the restricted chain to pass through it, the chain must be pulled or flow through the restrictions. The mechanism for movement of the chain through these restrictions is called reptation.

In the blob model,[13] the polymer chain is made up of Kuhn lengths of individual length . The chain is assumed to form blobs between each entanglement, containing Kuhn length segments in each. The mathematics of random walks can show that the average end-to-end distance of a section of a polymer chain, made up of Kuhn lengths is . Therefore if there are total Kuhn lengths, and blobs on a particular chain:

The total end-to-end length of the restricted chain is then:

This is the average length a polymer molecule must diffuse to escape from its particular tube, and so the characteristic time for this to happen can be calculated using diffusive equations. A classical derivation gives the reptation time :

where is the coefficient of friction on a particular polymer chain, is Boltzmann's constant, and is the absolute temperature.

The linear macromolecules reptate if the length of macromolecule is bigger than the critical entanglement molecular weight . is 1.4 to 3.5 times .[14] There is no reptation motion for polymers with , so that the point is a point of dynamic phase transition.

Due to the reptation motion the coefficient of self-diffusion and conformational relaxation times of macromolecules depend on the length of macromolecule as and , correspondingly.[15][16] The conditions of existence of reptation in the thermal motion of macromolecules of complex architecture (macromolecules in the form of branch, star, comb and others) have not been established yet.

The dynamics of shorter chains or of long chains at short times is usually described by the Rouse model.

See also

References

- Pokrovskii, V. N. (2010). The Mesoscopic Theory of Polymer Dynamics. Springer Series in Chemical Physics. Vol. 95. Bibcode:2010mtpd.book.....P. doi:10.1007/978-90-481-2231-8. ISBN 978-90-481-2230-1.

- Rubinstein, Michael (March 2008). Dynamics of Entangled Polymers. Pierre-Gilles de Gennes Symposium. New Orleans, LA: American Physical Society. Retrieved 6 April 2015.

- De Gennes, P. G. (1983). "Entangled polymers". Physics Today. 36 (6): 33. Bibcode:1983PhT....36f..33D. doi:10.1063/1.2915700.

A theory based on the snake-like motion by which chains of monomers move in the melt is enhancing our understanding of rheology, diffusion, polymer-polymer welding, chemical kinetics and biotechnology

- De Gennes, P. G. (1971). "Reptation of a Polymer Chain in the Presence of Fixed Obstacles". The Journal of Chemical Physics. 55 (2): 572. Bibcode:1971JChPh..55..572D. doi:10.1063/1.1675789.

- Samuel Edwards: Boltzmann Medallist 1995, IUPAP Commission on Statistical Physics, archived from the original on 2013-10-17, retrieved 2013-02-20

- Doi, M.; Edwards, S. F. (1978). "Dynamics of concentrated polymer systems. Part 1.?Brownian motion in the equilibrium state". Journal of the Chemical Society, Faraday Transactions 2. 74: 1789–1801. doi:10.1039/f29787401789.

- Bu, Z; Cook, J; Callaway, D. J. (2001). "Dynamic regimes and correlated structural dynamics in native and denatured alpha-lactalbumin". Journal of Molecular Biology. 312 (4): 865–73. doi:10.1006/jmbi.2001.5006. PMID 11575938.

- Barkema, G. T.; Panja, D.; Van Leeuwen, J. M. J. (2011). "Structural modes of a polymer in the repton model". The Journal of Chemical Physics. 134 (15): 154901. arXiv:1102.1394. Bibcode:2011JChPh.134o4901B. doi:10.1063/1.3580287. PMID 21513412. S2CID 1979411.

- Rubinstein, M. (1987). "Discretized model of entangled-polymer dynamics". Physical Review Letters. 59 (17): 1946–1949. Bibcode:1987PhRvL..59.1946R. doi:10.1103/PhysRevLett.59.1946. PMID 10035375.

- McLeish, T. C. B. (2002). "Tube theory of entangled polymer dynamics". Advances in Physics. 51 (6): 1379–1527. Bibcode:2002AdPhy..51.1379M. CiteSeerX 10.1.1.629.3682. doi:10.1080/00018730210153216. S2CID 122657744.

- Berry, G. C.; Fox, T. G. (1968). "The viscosity of polymers and their concentrated solutions". Fortschritte der Hochpolymeren-Forschung. Advances in Polymer Science. Vol. 5/3. Springer Berlin Heidelberg. p. 261. doi:10.1007/BFb0050985. ISBN 978-3-540-04032-3.

- Edwards, S. F. (1967). "The statistical mechanics of polymerized material". Proceedings of the Physical Society. 92 (1): 9–16. Bibcode:1967PPS....92....9E. doi:10.1088/0370-1328/92/1/303.

- Duhamel, J.; Yekta, A.; Winnik, M. A.; Jao, T. C.; Mishra, M. K.; Rubin, I. D. (1993). "A blob model to study polymer chain dynamics in solution". The Journal of Physical Chemistry. 97 (51): 13708. doi:10.1021/j100153a046.

- Fetters, LJ; Lohse, DJ; Colby, RH (2007). "25.3". In Mark, James E (ed.). Chain Dimensions and Entanglement Spacings in "Physical properties of polymers handbook" (2nd ed.). New York: Springer New York. p. 448. ISBN 978-0-387-69002-5.

- Pokrovskii, V. N. (2006). "A justification of the reptation-tube dynamics of a linear macromolecule in the mesoscopic approach". Physica A: Statistical Mechanics and Its Applications. 366: 88–106. Bibcode:2006PhyA..366...88P. doi:10.1016/j.physa.2005.10.028.

- Pokrovskii, V. N. (2008). "Reptation and diffusive modes of motion of linear macromolecules". Journal of Experimental and Theoretical Physics. 106 (3): 604–607. Bibcode:2008JETP..106..604P. doi:10.1134/S1063776108030205. S2CID 121054836.