Stereolithography

Stereolithography (SLA or SL; also known as vat photopolymerisation,[1] optical fabrication, photo-solidification, or resin printing) is a form of 3D printing technology used for creating models, prototypes, patterns, and production parts in a layer by layer fashion using photochemical processes by which light causes chemical monomers and oligomers to cross-link together to form polymers.[2] Those polymers then make up the body of a three-dimensional solid. Research in the area had been conducted during the 1970s, but the term was coined by Chuck Hull in 1984 when he applied for a patent on the process, which was granted in 1986.[3] Stereolithography can be used to create prototypes for products in development, medical models, and computer hardware, as well as in many other applications. While stereolithography is fast and can produce almost any design, it can be expensive.

History

Stereolithography or "SLA" printing is an early and widely used 3D printing technology. In the early 1980s, Japanese researcher Hideo Kodama first invented the modern layered approach to stereolithography by using ultraviolet light to cure photosensitive polymers.[4][5] In 1984, just before Chuck Hull filed his own patent, Alain Le Mehaute, Olivier de Witte and Jean Claude André filed a patent for the stereolithography process.[6] The French inventors' patent application was abandoned by the French General Electric Company (now Alcatel-Alsthom) and CILAS (The Laser Consortium). Le Mehaute believes that the abandonment reflects a problem with innovation in France.[7][8]

The term “stereolithography” (Greek: stereo-solid and lithography) was coined in 1984 by Chuck Hull when he filed his patent for the process.[2][9] Hull patented stereolithography as a method of creating 3D objects by successively "printing" thin layers of an object using a medium curable by ultraviolet light, starting from the bottom layer to the top layer. Hull's patent described a concentrated beam of ultraviolet light focused onto the surface of a vat filled with a liquid photopolymer. The beam is focused onto the surface of the liquid photopolymer, creating each layer of the desired 3D object by means of crosslinking (generation of intermolecular bonds in polymers). It was invented with the intent of allowing engineers to create prototypes of their designs in a more time effective manner.[4][10] After the patent was granted in 1986,[2] Hull co-founded the world's first 3D printing company, 3D Systems, to commercialize it.[11]

Stereolithography's success in the automotive industry allowed 3D printing to achieve industry status and the technology continues to find innovative uses in many fields of study.[10][12] Attempts have been made to construct mathematical models of stereolithography processes and to design algorithms to determine whether a proposed object may be constructed using 3D printing.[13]

Technology

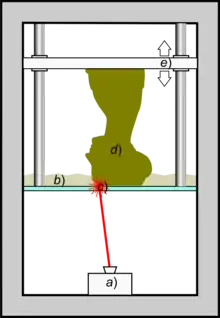

Stereolithography is an additive manufacturing process that, in its most common form, works by focusing an ultraviolet (UV) laser on to a vat of photopolymer resin.[14] With the help of computer aided manufacturing or computer-aided design (CAM/CAD) software,[15] the UV laser is used to draw a pre-programmed design or shape on to the surface of the photopolymer vat. Photopolymers are sensitive to ultraviolet light, so the resin is photochemically solidified and forms a single layer of the desired 3D object.[16] Then, the build platform lowers one layer and a blade recoats the top of the tank with resin.[5] This process is repeated for each layer of the design until the 3D object is complete. Completed parts must be washed with a solvent to clean wet resin from their surfaces.[17]

It is also possible to print objects "bottom up" by using a vat with a transparent bottom and focusing the UV or deep-blue polymerization laser upward through the bottom of the vat.[17] An inverted stereolithography machine starts a print by lowering the build platform to touch the bottom of the resin-filled vat, then moving upward the height of one layer. The UV laser then writes the bottom-most layer of the desired part through the transparent vat bottom. Then the vat is "rocked", flexing and peeling the bottom of the vat away from the hardened photopolymer; the hardened material detaches from the bottom of the vat and stays attached to the rising build platform, and new liquid photopolymer flows in from the edges of the partially built part. The UV laser then writes the second-from-bottom layer and repeats the process. An advantage of this bottom-up mode is that the build volume can be much bigger than the vat itself, and only enough photopolymer is needed to keep the bottom of the build vat continuously full of photopolymer. This approach is typical of desktop SLA printers, while the right-side-up approach is more common in industrial systems.[5]

Stereolithography requires the use of supporting structures which attach to the elevator platform to prevent deflection due to gravity, resist lateral pressure from the resin-filled blade, or retain newly created sections during the "vat rocking" of bottom up printing. Supports are typically created automatically during the preparation of CAD models and can also be made manually. In either situation, the supports must be removed manually after printing.[5]

Other forms of stereolithography build each layer by LCD masking, or using a DLP projector.[18]

Materials

The liquid materials used for SLA printing are commonly referred to as "resins" and are thermoset polymers. A wide variety of resins are commercially available and it is also possible to use homemade resins to test different compositions for example. Material properties vary according to formulation configurations: "materials can be soft or hard, heavily filled with secondary materials like glass and ceramic, or imbued with mechanical properties like high heat deflection temperature or impact resistance".[19] Recently, some studies have tested the possibility to green[20] or reusable[21] materials to produce "sustainable" resins. It is possible to classify the resins in the following categories:[22]

- Standard resins, for general prototyping

- Engineering resins, for specific mechanical and thermal properties

- Dental and medical resins, for biocompatibility certifications

- Castable resins, for zero ash-content after burnout

- Biomaterial resins, formulated as aqueous solutions of synthetic polymers like polyethylene glycol, or biological polymers such as gelatin, dextran, or hyaluronic acid.

Uses

Medical modeling

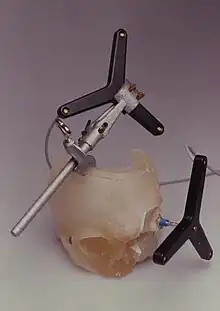

Stereolithographic models have been used in medicine since the 1990s,[23] for creating accurate 3D models of various anatomical regions of a patient, based on data from computer scans.[24] Medical modelling involves first acquiring a CT, MRI, or other scan.[25] This data consists of a series of cross sectional images of the human anatomy. In these images different tissues show up as different levels of grey. Selecting a range of grey values enables specific tissues to be isolated. A region of interest is then selected and all the pixels connected to the target point within that grey value range are selected. This enables a specific organ to be selected. This process is referred to as segmentation. The segmented data may then be translated into a format suitable for stereolithography.[26] While stereolithography is normally accurate, the accuracy of a medical model depends on many factors, especially the operator performing the segmentation correctly. There are potential errors possible when making medical models using stereolithography but these can be avoided with practice and well trained operators.[27]

Stereolithographic models are used as an aid to diagnosis, preoperative planning and implant design and manufacture. This might involve planning and rehearsing osteotomies, for example. Surgeons use models to help plan surgeries[28] but prosthetists and technologists also use models as an aid to the design and manufacture of custom-fitting implants. For instance, medical models created through stereolithography can be used to help in the construction of Cranioplasty plates.[29][30]

In 2019, scientists at Rice University published an article in the journal Science, presenting soft hydrogel materials for stereolithography used in biological research applications.[31]

Advantages and disadvantages

Advantages

One of the advantages of stereolithography is its speed; functional parts can be manufactured within a day.[10] The length of time it takes to produce a single part depends upon the complexity of the design and the size. Printing time can last anywhere from hours to more than a day.[10] SLA printed parts, unlike those obtained from FFF/FDM, do not exhibit significant anisotropy and there's no visible layering pattern. The surface quality is, in general, superior. Prototypes and designs made with stereolithography are strong enough to be machined[33][34] and can also be used to make master patterns for injection molding or various metal casting processes.[33]

Disadvantages

Although stereolithography can be used to produce virtually any synthetic design,[15] it is often costly, though the price is coming down. Since 2012,[35] however, public interest in 3D printing has inspired the design of several consumer SLA machines which can cost considerably less. Beginning in 2016, substitution of the SLA and DLP methods using a high resolution, high contrast LCD panel has brought prices down to below US$200. The layers are created in their entirety since the entire layer is displayed on the LCD screen and is exposed using UV LEDs that lie below. Resolutions of .01mm are attainable. Another disadvantage is that the photopolymers are sticky, messy, and need to be handled with care. Newly made parts need to be washed, further cured, and dried. The environmental impact of all these processes requires more study to be understood, but in general SLA technologies have not created any biodegradable or compostable forms of resin, while other 3-D printing methods offer some compostable PLA options. The choice of materials is limited compared to FFF, which can process virtually any thermoplastic.

See also

- Fused filament fabrication (FFF or FDM)

- Selective laser sintering (SLS)

- Thermoforming

- laminated object manufacturing (LOM)

References

- ISO/ASTM 52900 Standard. Additive manufacturing. General principles. Fundamentals and vocabulary.

- U.S. Patent 4,575,330 (“Apparatus for Production of Three-Dimensional Objects by Stereolithography”)

- "US Patent for Apparatus for production of three-dimensional objects by stereolithography Patent (Patent # 4,575,330 issued March 11, 1986) - Justia Patents Search". patents.justia.com. Retrieved 2019-04-24.

- Gibson, Ian, and Jorge Bártolo, Paulo. “History of Stereolithography.” Stereolithography: Materials, Processes, and Applications. (2011): 41-43. Print. 7 October 2015.

- "The Ultimate Guide to Stereolithography (SLA) 3D Printing". Formlabs. Formlabs, Inc. Retrieved 26 December 2017.

- Jean-Claude, Andre. "Disdpositif pour realiser un modele de piece industrielle". National De La Propriete Industrielle.

- Moussion, Alexandre (2014). "Interview d'Alain Le Méhauté, l'un des pères de l'impression 3D". Primante 3D.

- Mendoza, Hannah Rose (May 15, 2015). "Alain Le Méhauté, The Man Who Submitted Patent For SLA 3D Printing Before Chuck Hull". 3dprint.com. 3DR Holdings, LLC.

- "Stereolithography / 3D Printing / Additive Fabrication". Photopolymers. Savla Associates. Archived from the original on 14 February 2008. Retrieved 10 August 2017.

- Hull, Chuck (2012). "On Stereolithography". Virtual and Physical Prototyping. 7 (3): 177. doi:10.1080/17452759.2012.723409. S2CID 219623097.

- "Our Story". 3D Systems. 3D Systems, Inc. 12 January 2017. Retrieved 10 August 2017.

- Jacobs, Paul F. “Introduction to Rapid Prototyping and Manufacturing.” Rapid Prototyping and Manufacturing: Fundamentals of Stereolithography. 1st Ed. (1992): 4-6. Print. 7 October 2015.

- B. Asberg, G. Blanco, P. Bose, J. Garcia-Lopez, M. Overmars, G. Toussaint, G. Wilfong and B. Zhu, "Feasibility of design in stereolithography," Algorithmica, Special Issue on Computational Geometry in Manufacturing, Vol. 19, No. 1/2, Sept/Oct, 1997, pp. 61–83.

- Crivello, James V., and Elsa Reichmanis. "Photopolymer Materials and Processes for Advanced Technologies." Chemistry of Materials Chem. Mater. 26.1 (2014): 533. Print.

- Lipson, Hod, Francis C. Moon, Jimmy Hai, and Carlo Paventi. "3-D Printing the History of Mechanisms." Journal of Mechanical Design J. Mech. Des. (2004): 1029-033. Print.

- Fouassier, J. P. "Photopolymerization Reactions." The Wiley Database of Polymer Properties 3 (2003): 25. Print.

- Ngo, Dong. "Formlabs Form 2 3D Printer review: An excellent 3D printer for a hefty price". CNET. Retrieved 3 August 2016.

More specifically, as the print platform lowers itself into the resin glass tank, an ultraviolet laser light, from underneath the see-through tank, shines on it. (For this reason, SLA is sometimes called the laser 3D-printing technology.) Exposed to the laser light, the resin cures, solidifies and sticks to the platform. As more resin is exposed to the laser light, the pattern is created and joins the layer above. As more and more layers are being created, the build platform slowly -- very slowly -- moves upward, finally pulling the entire object out of the tank as the print process is finished.

- rsilvers. "On the difference between DLP and LCD based SLA printers | Matter Replicator". Retrieved 2019-03-17.

- "The Ultimate Guide to Stereolithography (SLA) 3D Printing (Updated for 2020)". Formlabs. Retrieved 2020-10-21.

- Wu, B.; Sufi, A.; Biswas, R.G.; Hisatsune, A.; Moxley-Paquette, V.; Ning, P.; Soong, R.; Dicks, A.P. & Simpson, A.J. (2019). "Direct Conversion of McDonald's Waste Cooking Oil into a Biodegradable High-Resolution 3D-Printing Resin". ACS Sustainable Chemistry & Engineering. doi:10.1021/acssuschemeng.9b06281.

- Shi, Q.; Yu, K.; Kuang, X.; Mu, X.; Dunn, C.K.; Dunn, M.L.; Wang, T. & Qi, H.J. (2017). "Recyclable 3D printing of vitrimer epoxy". Materials Horizons. doi:10.1039/C7MH00043J.

- "SLA 3D printing materials compared". 3D Hubs. Retrieved 2020-10-21.

- Klimek, L; Klein HM; Schneider W; Mosges R; Schmelzer B; Voy ED (1993). "Stereolithographic modelling for reconstructive head surgery". Acta Oto-Rhino-Laryngologica Belgica. 47 (3): 329–34. PMID 8213143.

- Bouyssie, JF; Bouyssie S; Sharrock P; Duran D (1997). "Stereolithographic models derived from x-ray computed tomography. Reproduction accuracy". Surgical and Radiologic Anatomy. 19 (3): 193–9.

- Winder, RJ; Bibb, R (2009). "A Review of the Issues Surrounding Three-Dimensional Computed Tomography for Medical Modelling using Rapid Prototyping Techniques". Radiography. 16: 78–83. doi:10.1016/j.radi.2009.10.005.

- Bibb, Richard (2006). Medical Modelling: the application of advanced design and development technologies in medicine. Cambridge: Woodhead Publishing Ltd. ISBN 978-1-84569-138-7.

- Winder, RJ; Bibb, R (2005). "Medical Rapid Prototyping Technologies: State of the Art and Current Limitations for Application in Oral and Maxillofacial Surgery". Journal of Oral and Maxillofacial Surgery. 63 (7): 1006–15. doi:10.1016/j.joms.2005.03.016. PMID 16003630.

- "Applications of SLA". Stereolithography. Retrieved 7 October 2016.

- D'Urso, Paul; Effeney, David; Earwaker, W. John; Barker, Timothy; Redmond, Michael; Thompson, Robert; Tomlinson, Francis (April 2000). "Custom cranioplasty using stereolithography and acrylic". British Journal of Plastic Surgery. 53 (3): 200–204. doi:10.1054/bjps.1999.3268. PMID 10738323.

- Klein, H. M.; Schneider, W.; Alzen, G.; Voy, E.D.; Günther, R. W. (October 1992). "Pediatric craniofacial surgery: Comparison of milling and stereolithography for 3D model manufacturing". Pediatric Radiology. 22 (6): 458–460. doi:10.1007/BF02013512. PMID 1437375. S2CID 12820200.

- "AAAS".

- Palermo, Elizabeth (16 July 2013). "What is Stereolithography?". Live Science. Purch Group. Retrieved 7 October 2016.

- "Sterolithography". Proto3000. Proto3000 Inc. Retrieved 22 June 2018.

- "3D Print technologies". Luma 3D Print. LUMA-iD Ltd. Retrieved 22 June 2018.

- Prindle, Drew (6 June 2017). "With lasers and hot nylon, Formlabs just took 3D printing to a whole new level". Digital Trends. Designtechnica Corporation. Retrieved 24 September 2018.

Sources

- Kalpakjian, Serope, and Steven R. Schmid (2006). Manufacturing Engineering and Technology, 5th edition. Ch. 20. Upper Saddle River, NJ: Pearson Prentice Hall. pp. 586–587.

External links

- Rapid Prototyping and Stereolithography animation – Animation demonstrates stereolithography and the actions of an SL machine