T-slot structural framing

T-slot structural framing is a framing system consisting of lengths of square or rectangular extruded aluminium, typically 6105-T5 aluminium alloy, with a T-slot down the centerline of one or more sides.

It is also known under several generic names, such as aluminium extrusion, aluminium profile and 2020 extrusion if the cross-section is 20x20 mm, alongside brand names, such as 80/20 framing.[1]

While the precise history of the T-slot framing system is not known, advancement in extrusion press technology in the early 1950s allowed for economic production of aluminium profiles,[2] and examples of use can be found from the early 1960s.[3]

Although no published standard defines the system, it is produced in a series of conventional sizes which allows for compatibility between manufacturers.

There is a variation on T-slot profiles known as V-slot rails where V-slot wheels are slotted into the V-shaped channels of the framing for linear motion in a 3D printer or other CNC machine.

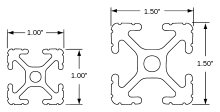

Profiles

T-slot framing is divided into metric and fractional (imperial) categories. The T-slot is always centered along the long-axis of the piece. Pieces are available in each series with a square cross-section. Rectangular cross sections are also available which measure x by 2x (where x is the defined width) - e.g. 40mm by 80mm for 40 series.

| Profile type |

Profile name |

Profile size |

|---|---|---|

| fractional | 10 series | 1" |

| 15 series | 1.5" | |

| metric | 20 series | 20 mm |

| 25 series | 25 mm | |

| 30 series | 30 mm | |

| 40 series | 40 mm | |

| 45 series | 45 mm |

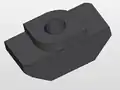

CAD model of a rotating T-slot nut used with aluminium T-slots/ T-track/ extrusions

CAD model of a rotating T-slot nut used with aluminium T-slots/ T-track/ extrusions

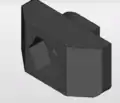

T-nut (red) installed in a T-slot

T-nut (red) installed in a T-slot

Calculating load capacity and deflection

Formulas depend on the type of fastening of the aluminium profile:[4]

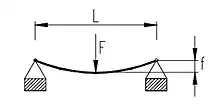

Simple supports

i.e. supported by swivel supports/joints at both sides:

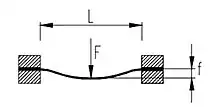

Fixed supports

i.e. supported by rigid supports/joints at both sides:

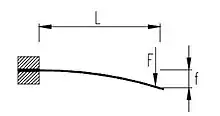

Cantilever

i.e. supported by a rigid support/joint at one side:

where:

- is the bending tension;

- is the force or load;

- is the free profile length;

- is the moment of resistance;

- is the moment of inertia;

- is the deflection;

- is the elasticity module;

- is the maximum bending tension.

| Constant load | Pulsating load | Alternating load | |

|---|---|---|---|

| 100 | 40 | 30 |

See also

References

- "Find out About Our Mission and Vision Here at 80/20". 8020.net. Archived from the original on 2022-03-06. Retrieved 2022-05-15.

- Bauser, M; Sauer, G; Siegert, K (2006). Extrusion (2 ed.). Materials Park, Ohio: ASM International. p. 6. ISBN 978-0-87170-837-3.

- US patent US3143981A, Leslie E Tassell, "Demountable partition", published 1964-08-11, issued 1964-08-11, assigned to Tassell Hardware Co

- "Aluminium profile load capacity | Blog - Tuli experience". www.tuli-shop.com. Retrieved 2023-09-26.