Pit latrine

A pit latrine, also known as pit toilet, is a type of toilet that collects human feces in a hole in the ground.[2] Urine and feces enter the pit through a drop hole in the floor, which might be connected to a toilet seat or squatting pan for user comfort.[2] Pit latrines can be built to function without water (dry toilet) or they can have a water seal (pour-flush pit latrine).[7] When properly built and maintained, pit latrines can decrease the spread of disease by reducing the amount of human feces in the environment from open defecation.[4][8] This decreases the transfer of pathogens between feces and food by flies.[4] These pathogens are major causes of infectious diarrhea and intestinal worm infections.[8] Infectious diarrhea resulted in about 700,000 deaths in children under five years old in 2011 and 250 million lost school days.[8][9] Pit latrines are a low-cost method of separating feces from people.[4]

| Pit latrine | |

|---|---|

| Synonym | Pit toilet, household latrine, long drop |

.jpg.webp) | |

| A simple pit latrine with a squatting pan and shelter[1] | |

| Position in sanitation chain | User interface, collection and storage (on-site) |

| Application level | Household level |

| Management level | Household, public, shared |

| Inputs | Feces, urine[2] |

| Outputs | Fecal sludge[3] |

| Types | With or without water seal, single or twin pit |

| Construction cost | Cheapest form of basic sanitation[4] |

| Maintenance cost | US$2–12/person/year as of 2011 (not including emptying)[5] |

| Environmental concerns | Groundwater pollution[3] |

| Number of users | 1.8 billion people (2013)[6] |

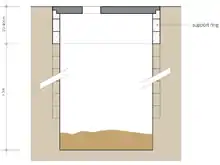

A pit latrine generally consists of three major parts: a hole in the ground, a concrete slab or floor with a small hole, and a shelter.[7] The shelter is also called an outhouse.[10] The pit is typically at least three meters (10 ft) deep and one meter (3 ft) across.[7] The hole in the slab should not be larger than 25 cm (10 in) to prevent children falling in.[4] Light should be prevented from entering the pit to reduce access by flies.[4] This may require the use of a lid to cover the hole in the floor when not in use.[4] The World Health Organization recommends the pits are built a reasonable distance from the house, balancing issues of easy access versus that of smell.[4] The distance from water wells and surface water should be at least 10 m (30 ft) to decrease the risk of groundwater pollution.[11] When the pit fills to within 0.5 m (1+1⁄2 ft) of the top, it should be either emptied or a new pit constructed and the shelter moved or re-built at the new location.[12] Fecal sludge management involves emptying pits as well as transporting, treating and using the collected fecal sludge.[3] If this is not carried out properly, water pollution and public health risks can occur.[3]

A basic pit latrine can be improved in a number of ways.[2] One includes adding a ventilation pipe from the pit to above the structure.[12] This improves airflow and decreases the smell of the toilet.[12] It also can reduce flies when the top of the pipe is covered with mesh (usually made out of fiberglass).[12] In these types of toilets a lid need not be used to cover the hole in the floor.[12] Other possible improvements include a floor constructed so fluid drains into the hole and a reinforcement of the upper part of the pit with bricks, blocks, or cement rings to improve stability.[7][12] In developing countries the cost of a simple pit toilet is typically between US$25 and $60.[13] Recurring expenditure costs are between US$1.5 and $4 per person per year for a traditional pit latrine, and up to three times higher for a pour flush pit latrine (without the costs of emptying).[5]

As of 2013 pit latrines are used by an estimated 1.77 billion people, mostly in developing countries.[6] About 892 million people (12 percent of the global population) practiced open defecation in 2016, mostly because they have no toilets.[14] Southern Asia and Sub-Saharan Africa have the lowest access to toilets.[14] The Indian government has been running a campaign called "Swachh Bharat Abhiyan" (Clean India Mission in English) since 2014 in order to eliminate open defecation by convincing people in rural areas to purchase, construct and use toilets, mainly pit latrines.[15][16] As a result, sanitation coverage in India has increased from just 39% in October 2014 to almost 98% in 2019.[17] It is estimated that 85 million pit latrines have been built due to that campaign as of 2018.[18][19] Another example from India is the "No Toilet, No Bride" campaign which promotes toilet uptake by encouraging women to refuse to marry men who do not own a toilet.[20][21]

Definitions

Depending on the region, the term "pit latrine" may be used to denote a toilet that has a squatting pan with a water seal or siphon (more accurately termed a pour-flush pit latrine – very common in South East Asia for example) or simply a hole in the ground without a water seal (also called a simple pit latrine) – the common type in most countries in sub-Saharan Africa. Whilst a dry toilet can be with or without urine diversion, a pit latrine is almost always without urine diversion. The key characteristic of a pit latrine is the use of a pit, which infiltrates liquids into the ground and acts as a device for storage and very limited treatment.[7]

Pit latrines are sometimes also referred to as "dry toilets". However, some pit latrines do use water for flushing and are therefore not a "dry toilet". Dry toilets is an overarching term used for several types of toilets, and only refers to the type of user interface, not the storage or treatment part.[7]

Improved or unimproved sanitation

A pit latrine may or may not count towards the Millennium Development Goals (MDG) target of increasing access to sanitation for the world's population, depending on the type of pit latrine: A pit latrine without a slab is regarded as unimproved sanitation and does not count towards the target. A pit latrine with a slab, a ventilated improved pit latrine and a pour flush pit latrine connected to a pit or septic tank are counted as being "improved sanitation" facilities as they are more likely to hygienically separate human excreta from human contact.[22]

Design considerations

Size of the drop hole

The user positions themself over the small drop hole during use. The size of the feces drop hole in the floor or slab should not be larger than 25 cm (10 in) to prevent children falling in. Light should be prevented from entering the pit to reduce access by flies.

Lids on the drop hole or toilet seat

A lid on the drop hole keeps light out of the pit and helps to stop flies and odors entering the toilet's superstructure. The lid can be made from plastic or wood and is used to cover the hole in the floor when the pit latrine is not in use.[4] In practice, such a lid is not commonly used for squatting type pit latrines but only for sitting type pit latrines with a toilet seat.

Squatting pan or toilet seat

On top of the drop hole there can either be nothing (this is the simplest form of a pit latrine) or there can be a squatting pan, seat (pedestal) or bench which can be made of concrete, ceramic, plastic or wood.

Shelter

A shelter, shed, small building or "super-structure" houses the squatting pan or toilet seat and provides privacy and protection from the weather for the user. Ideally, the shelter or small building should have handwashing facilities available inside or on the outside (e.g. supplied with water from a rainwater harvesting tank on the roof of the shelter) although this is unfortunately rarely the case in practice. In the shelter, anal cleansing materials (e.g. toilet paper) and a solid waste bin should also be available. A more substantial structure may also be built, commonly known as an outhouse.

Locating the pit

Liquids leach from the pit and pass the unsaturated soil zone (which is not completely filled with water). Subsequently, these liquids from the pit enter the groundwater where they may lead to groundwater pollution. This is a problem if a nearby water well is used to supply groundwater for drinking water purposes. During the passage in the soil, pathogens can die off or be absorbed significantly, mostly depending on the travel time between the pit and the well.[23] Most, but not all pathogens die within 50 days of travel through the subsurface.[24]

The degree of pathogen removal strongly varies with soil type, aquifer type, distance and other environmental factors.[6] For this reason, it is difficult to estimate the safe distance between a pit and a water source – a problem that also applies to septic tanks. Detailed guidelines have been developed to estimate safe distances to protect groundwater sources from pollution from on-site sanitation.[25][26] However, these are mostly ignored by those building pit latrines. In addition to that, household plots are of a limited size and therefore pit latrines are often built much closer to groundwater wells than what can be regarded as safe. This results in groundwater pollution and household members falling sick when using this groundwater as a source of drinking water.

As a very general guideline it is recommended that the bottom of the pit should be at least 2 metres (6') above groundwater level, and a minimum horizontal distance of 30 metres (yards) between a pit and a water source is normally recommended to limit exposure to microbial contamination.[1]However, no general statement should be made regarding the minimum lateral separation distances required to prevent contamination of a well from a pit latrine.[27] For example, even 50 metres (yards) lateral separation distance might not be sufficient in a strongly karstified system with a downgradient supply well or spring, while 10 metres (yards) lateral separation distance is completely sufficient if there is a well developed clay cover layer and the annular space of the groundwater well is well sealed.

If the local hydrogeological conditions (which can vary within a space of a few square kilometres; a square mile or two) are ignored, pit latrines can cause significant public health risks via contaminated groundwater. In addition to the issue of pathogens, there is also the issue of nitrate pollution in groundwater from pit latrines. Elevated nitrate levels in drinking water from private wells is thought to have caused cases of blue baby syndrome in children in rural areas of Romania and Bulgaria in Eastern Europe.[28]

Partial

A "partially lined" pit latrine is one where the upper part of the hole in the ground is lined. Pit lining materials can include brick, rot-resistant timber, concrete, stones, or mortar plastered onto the soil.[7] This partial lining is recommended for those pit latrine used by a great number of people — such as a public restroom in rural areas, or in a woodland park or busy lay-by, rest stop or other similarly busy location — or where the soils are unstable in order to increase permanence and allow emptying of the pit without it collapsing easily. The bottom of the pit should remain unlined to allow for the infiltration of liquids out of the pit.

Fully

A fully lined pit latrine has concrete lining also at the base so that no liquids infiltrate into the ground. One could argue that this is no longer a "pit" latrine in the stricter sense. The advantage is that no groundwater contamination can occur. The major disadvantage is that a fully lined pit latrine fills up very fast (as the urine cannot escape the pit) which results in high costs to empty and maintain the latrine. Increased odour can also be an issue as the pit content is much wetter and emits more odour. This type of pit latrine is used only in special circumstances, e.g. in denser settlements where groundwater protection is paramount.

Appropriateness

Pit latrines are often built in developing countries even in situations where they are not recommended. These include (adapted from[29]):

- Frequent flooding, resulting in inoperable toilet systems and the contamination of water resources;

- Unfavourable soil conditions, such as unstable or rocky soil and high water table, making pit-based sanitation difficult and expensive;

- When groundwater is the primary source of drinking water and is likely to be contaminated by pit-based sanitation (for example in denser settlements or with unfavourable hydrogeological conditions);

- Limited land space restricts the excavation of new pits if full pit latrines are usually not emptied;

- Indoor installations are preferred as they provide greater comfort and security at night thus making them more accessible for all

In conditions where pit latrines are not suitable for the above-mentioned reasons, the installations of other types of toilets should be considered, e.g. the urine-diverting dry toilet (UDDT).[29]

Types

Pit latrines collect human feces in a hole in the ground. The principle of a pit latrine is that all liquids that enter the pit—in particular urine and water used for anal cleansing—seep into the ground (the only exception are fully lined pit latrines, see below).

.jpg.webp) Well maintained pit latrine at a rural household near Maseru, Lesotho.

Well maintained pit latrine at a rural household near Maseru, Lesotho._(2937872226).jpg.webp) Pit latrine from the inside at a household near Maseru, Lesotho (same toilet as shown left from the outside).

Pit latrine from the inside at a household near Maseru, Lesotho (same toilet as shown left from the outside)..jpg.webp) School children in Zimbabwe digging a shallow pit for an Arborloo toilet (a variation of a pit latrine), Epworth in Harare, Zimbabwe.

School children in Zimbabwe digging a shallow pit for an Arborloo toilet (a variation of a pit latrine), Epworth in Harare, Zimbabwe. Traditional pit latrine in North Kamenya, Kenya.

Traditional pit latrine in North Kamenya, Kenya. This display shows children what toilets in rural areas in Germany used to look like in the recent past.

This display shows children what toilets in rural areas in Germany used to look like in the recent past..jpg.webp) Abandoned pit latrine in the peri-urban area of Durban, South Africa.

Abandoned pit latrine in the peri-urban area of Durban, South Africa. Interior of an outhouse the structure usually built over the pit to provide privacy.

Interior of an outhouse the structure usually built over the pit to provide privacy.

Ventilated improved pit

The ventilated improved pit latrine (VIP) is a pit latrine with a black pipe (vent pipe) fitted to the pit and a screen (flyscreen) at the top outlet of the pipe. VIP latrines are an improvement to overcome the disadvantages of simple pit latrines, e.g. fly and mosquito nuisance and unpleasant odors. The smell is carried upwards by the chimney effect and flies are prevented from leaving the pit and spreading disease.[7] Despite their simplicity, well-designed single VIPs can be completely smell free, and more pleasant to use than some other water-based technologies. Flies that hatch in the pit are attracted to the light at the top of the ventilation pipe. When they fly towards the light and try to escape, they are trapped by the flyscreen and die. The ventilation also allows odours to escape and minimizes the attraction for flies.[30]

The principal mechanism of ventilation in VIP latrines is the action of wind blowing across the top of the vent pipe. The wind creates a strong circulation of air through the superstructure, down through the squat hole, across the pit and up and out of the vent pipe. Unpleasant fecal odors from the pit contents are thus sucked up and exhausted out of vent pipe, leaving the superstructure odor-free. In some cases solar-powered fans are added giving a constant outwards flow from the vent pipe.

Flies searching for an egg-laying site are attracted by fecal odors coming from the vent pipe, but they are prevented from entering by the flyscreen at the outlet of the vent pipe. Some flies may enter into the pit via the squat hole and lay their eggs there. When new adult flies emerge, they instinctively fly towards light. However, if the latrine is dark inside, the only light they can see is at the top of the vent pipe. Since the vent pipe is covered by a fly screen at the top, flies will not be able to escape and eventually will die and fall back into the pit.

To ensure that there is a flow of air through the latrine, there must be adequate ventilation of the superstructure. This is usually achieved by leaving openings above and below the door, or by constructing a spiral wall without a door.[31]

Covering the feces with an absorbent decreases smell and discourages flies. These may include soil, sawdust, ash, or lime, among others.[12] In developing countries, the use of absorbents in pit toilets is not commonly practiced.

The vent pipe should have an internal diameter of at least 110 mm (4¼") and reach more than 300 mm (12") above the highest point of the toilet superstructure. Wind passing over the top creates a suction pressure within the vent pipe and induces an air circulation. Air is drawn through the User Interface into the pit, moves up inside the vent pipe and escapes into the atmosphere. Care should be taken that objects, such as trees or houses, do not interfere with the air stream. The vent works best in windy areas, but where there is little wind, its effectiveness can be improved by painting the pipe black. The heat difference between the pit (cool) and the vent (warm) creates an updraft that pulls the air and odours up and out of the pit. To test the efficacy of the ventilation, a lit cigarette can be held over the User Interface; the smoke should be pulled down into the pit and up into the vent and not remain in the superstructure. The mesh size of the fly screen must be large enough to prevent clogging with dust and allow air to circulate freely. Aluminium screens, with a hole-size of 1.2 to 1.5 mm (approx. 1/20"), have proven to be the most effective. Typically, the pit is at least 3 metres (10') deep and 1 to 1.5 metres (3' to 5') in diameter, depending on the number of users. Deep pits can last up to 20 or more years.[30]

As liquid leaches from the pit and migrates through the unsaturated soil matrix, pathogenic germs are sorbed to the soil surface. In this way, pathogens can be removed prior to contact with groundwater. The degree of removal varies with soil type, distance travelled, moisture and other environmental factors and, thus, it is difficult to estimate the distance necessary between a pit and a water source. A minimum horizontal distance of 30 metres (100') between a pit and a water source and 2 metres (6') between the bottom of the pit and the groundwater table is normally recommended to limit exposure to microbial contamination.[30]

Twin pit designs

A further improvement is the use of a second pit which is used in alternation with the first pit. It means that the first pit can rest for the duration of time it takes to fill up the second pit. When the second pit is also full, then the first pit is emptied. The fecal sludge collected in that first pit has in the meantime undergone some degree of pathogen reduction although this is unlikely to be complete. This is a common design for so-called twin-pit pour flush toilets and increases the safety for those having to enter the pit.[7] Also VIP latrines are sometimes built with two pits, although for VIP toilets one problem can be that the users may not stick to this alternation method and fill up both pits at the same time.

The pits are of an adequate size to accommodate a volume of waste generated over one or two years. This allows the contents of the full pit enough time to transform into a partially sanitized, soil-like material that can be manually excavated. Twin pits are constructed 1 metre (3') apart from each other to minimize cross-contamination between the maturing pit and the one in use. Also pits are constructed over 1 metre (3') from any structural foundation as leachate can negatively impact structural supports. Water within the pit can impact its stability. Therefore, the full depth of the pit walls are lined to prevent collapse and the top 30 cm (12") are fully mortared to prevent direct infiltration and to support the superstructure.[30]

There is a risk of groundwater pollution when pits are located in areas with a high or variable water table, and/or fissures or cracks in the bedrock. As soil and groundwater properties are often unknown, it is difficult to estimate the distance necessary between a pit and a water source. It is normally recommended to have a minimum horizontal distance of 30 metres (yards) between them to limit exposing the water source to microbial contamination. To ensure that only one of the two pits is used at any time, the idle pipe of the junction connecting to the out -of- use pit is closed (e.g. with cement or bricks).[30]

Twin Pit Toilets are commonly used in rural India.[32] the Government's Swachh bharat Mission primarily used Twin pit toilets since they were easier and safer to remove and clean. Once removed the waste is used as manure to grow crops

Pour-flush pit latrine

.jpg.webp)

In a pour-flush pit latrine, a squatting or pedestal toilet with a water seal (U-trap or siphon) is used over one or two offset pits. Therefore, these types of toilets do require water for flushing but otherwise have many of the same characteristics as simple pit latrines. About one to three liters (quarts) of water is used per flush in that case, and they often have two pits that are used one after the other ("twin pit pour flush pit latrine"). For this reason they are subsumed under the term "pit latrine". The fecal sludge that is removed from the full pits of twin-pit pour-flush pit latrines is somewhat safer to handle and reuse than the fecal sludge from single pit pour-flush latrines. However, significant health risks for the workers who are emptying the pits remain in either case.

An alternative to U-trap or siphon designs is to incorporate a counter-weighted trap door mechanism that provides an air-tight water seal in the closed position.[33] Addition of a small amount of water (generally less than 500 ml; 1 pint) overcomes the counterweight and allows the fecal matter to enter the pit.[34] The devices are sold under the name of "SaTo pan" for as little as US$1.85, and more than 800,000 of them have been installed worldwide since introduction in 2013.[35]

Cat hole

A cat hole is a one-time-use pit toilet often utilized by campers, hikers and other outdoor recreationalists. Also referred to as the "cat method," it is formed by simply digging a hole in the ground just large enough to hold the feces from one defecation event. After use, the hole is refilled with the soil that was dug out.

Maintenance

.jpg.webp)

The requirements for safe pit emptying and fecal sludge management are often forgotten by those building pit latrines, as the pit will only fill up in a few years time. However, in many developing countries safe fecal sludge management practices are lacking and causing public health risks as well as environmental pollution.[36]

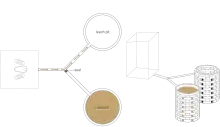

Pit emptying

When the pit is full, the toilet is no longer usable. The time it takes to fill the pit depends on its volume, the number of users, the soil permeability and groundwater level. It can typically take between one and ten years or even longer in some exceptional cases. At that point, the pit can be covered and abandoned, and a new pit latrine built if space on the property permits this. The new pit latrine may reuse the shelter (superstructure) if the shelter can be moved without collapsing.

In peri-urban or urban areas, full pits are not abandoned but rather emptied by sanitation workers or the household members themselves so that the toilets can continue to be used at the same location after the emptying has taken place. The emptying can be done manually with shovels and buckets, with manually powered pumps or with motorized pumps mounted on a vacuum truck which carries a tank for storage.[36] For the fecal sludge to be pumpable, water usually needs to be added to the pit and the content stirred up, which is messy and smelly.

Procedures for safe emptying of fecal sludge from pit latrines is a priority for many developing countries where many new pit latrines have been built in rural areas in recent years, such as in Bangladesh.[37][38]

Fecal sludge that has been removed from pits manually or with vacuum tankers is often dumped into the environment indiscriminately, leading to what has been called "institutionalized open defecation".

Sludge management

The fecal sludge may be transported by road to a sewage treatment facility, or to be composted elsewhere. There are numerous licensed waste hauling companies providing such service in areas where it is needed in developed countries, although in developing countries such services are not well regulated and are often carried out by untrained, unskilled and unprotected informal workers.

When managed and treated correctly to achieve a high degree of pathogen kill, fecal sludge from pit latrines could be used as a fertilizer due to its high nitrogen, phosphorus and organic matter content. However, it is hard to ensure that this is done in a safe manner. The number of viable helminth eggs is commonly used as an indicator organism to make a statement about the pathogen load in a fecal sludge sample. Helminth eggs are very persistent to most treatment methods and are therefore a good indicator.

Pit additives

A range of commercial products are available which claim to help reduce the volume of feces in the pit and reduce odor and fly problems. They are collectively described as a pit additive and many of them are based on the concept of effective microorganisms. The intention is to add specific strains of microbes to aid the decomposition process – but their effectiveness is disputed and recent research found no effect in scientific test conditions.[39][40]

Wood ash, leaves, soil, compost, or sawdust can be sprinkled on top of the feces to decrease the smell in the case of pit latrines without a water seal.[12] This is however not common practice for users in developing countries. Users often do not expect a pit latrine to be odour free, and endure the smell.

Advantages

Advantages of pit latrines may include:[7]

- Can be built and repaired with locally available materials

- Low (but variable) capital costs depending on materials and pit depth

- Small land area required

Measures to improve access to safe water, sanitation and better hygiene, which includes the use of pit latrines instead of open defecation, is believed to be able to prevent nearly 90% of deaths due to infectious diarrhea.[41]

Disadvantages

Disadvantages of pit latrines may include:[7]

- Flies and odours are normally noticeable to the users

- The toilet has to be outdoors with the associated security risks if the person is living in an insecure situation

- Low reduction in organic matter content and pathogens

- Possible contamination of groundwater with pathogens and nitrate

- Costs to empty the pits may be significant compared to capital costs

- Pit emptying is often done in a very unsafe manner

- Sludge (called fecal sludge) requires further treatment and/or appropriate discharge

- Pit latrines are often relocated or re-built after some years (when the pit is full and if the pit is not emptied) and thus need more space than urine-diverting dry toilets for example and people are less willing to invest in a high-quality super-structure as it will have to be dismantled at some point.

Costs

Construction

In developing countries the construction cost for a simple pit toilet is between about US$25 and 60.[13] This cost figure has a wide range because the costs vary a lot depending on the type of soil, the depth and reinforcement of the pit, the superstructure that the user is willing to pay for, the type of toilet squatting pan or toilet seat chosen, the cost of labour, construction materials (in particular the cost of cement can differ a lot from one country to the next), the ventilation system and so forth.

Rather than looking only at the construction cost, the whole of life cost (or life-cycle cost) should be considered, as the regular emptying or re-building of pit latrines may add a significant expense to the households in the longer term.[42]

In India, Japan's LIXIL Group has supplied tens of thousands of twin pit toilet systems that costs $10 or less apiece (in 2018).[15]

Recurrent expenditure

Recurring expenditure costs are between US$1.5 and $4 per person per year for a traditional pit latrine.[5] This includes operational and minor expenditure, capital maintenance expenditure and expenditure on direct support but does not include pit emptying costs. The total recurrent expenditure for more "upmarket" pit latrines has been estimated to be $2.5–8.5 for a VIP-type pit latrine and $3.5–11.5 for a pour-flush pit latrine.[5]

Society and culture

.jpg.webp)

Names

There are numerous colloquial names for pit latrines, such as "long drop", "dunny", "privy".

User experiences

.jpg.webp)

Pit latrines may or may not be an enjoyable experience to use. Problems may occur when the pit latrine is shared by too many people, is not cleaned daily and not emptied when the pit is full. In such cases, flies and odour can be a major nuisance. Also, pit latrines are usually dark places which are difficult to keep clean. Often, handwashing facilities are missing. For these reasons, shared pit latrines can be very uncomfortable to use in developing countries.

Alternative to open defecation

About 892 million people, or 12 percent of the global population, practiced open defecation in 2016, mostly because they have no toilets.[14] Southern Asia and Sub-Saharan Africa have the lowest access to toilets.[14] Pit latrines are a low-cost toilet option that do not require expensive infrastructure. As such, many government agencies and NGOs promote the construction of pit latrines in rural areas (groundwater pollution can be an issue).

The community-led total sanitation approach results in the spontaneous construction and sustained use of pit latrines rather than open defecation.

India example

The Indian government has been running the Swachh Bharat Abhiyan (Clean India Mission) since 2014 in order to eliminate open defecation and to convince people in rural areas to purchase, construct and use toilets, mainly pit latrines.[15] This campaign is a combination of building new toilets and encouraging behavior change. It is estimated that 50 million additional pit latrines have been built due to that campaign between 2014 and 2017.[18]

Another example is the campaign that took place in Haryana with slogans such as "No Toilet, No Bride" or "No loo, no "I do"". This campaign promotes the construction of toilets (usually pour flush pit latrine toilets).[20][21] In rural India, there are sometimes cultural preferences for open defecation and these may be difficult to overcome with unattractive toilet designs, such as pit latrines.[43]

See also

- Bucket toilet

- Cesspit

References

- WEDC (15 January 2011). Latrine slabs: an engineer's guide, WEDC Guide 005 (PDF). Water, Engineering and Development Centre The John Pickford Building School of Civil and Building Engineering Loughborough University. p. 22. ISBN 978-1-84380-143-6. Archived (PDF) from the original on 4 March 2016. Retrieved 22 May 2016.

- "Fact sheets on environmental sanitation". World Health Organization. Archived from the original on 7 September 2016. Retrieved 20 September 2018.

- Strande, Linda; Brdjanovic, Damir (2014). Faecal Sludge Management: Systems Approach for Implementation and Operation. IWA Publishing. pp. 1, 6, 46. ISBN 9781780404721.

- "Simple pit latrine (fact sheet 3.4)". who.int. 1996. Archived from the original on 3 March 2016. Retrieved 15 August 2014.

- Sanitation and Hygiene in Africa Where Do We Stand?. Intl Water Assn. 2013. p. 161. ISBN 978-1-78040-541-4. Archived from the original on 8 March 2017.

- Graham, JP; Polizzotto, ML (May 2013). "Pit latrines and their impacts on groundwater quality: a systematic review". Environmental Health Perspectives. 121 (5): 521–30. doi:10.1289/ehp.1206028. PMC 3673197. PMID 23518813.

- Tilley, E.; Ulrich, L.; Lüthi, C.; Reymond, Ph.; Zurbrügg, C. (2014). Compendium of Sanitation Systems and Technologies (2 ed.). Dübendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (Eawag). ISBN 978-3-906484-57-0.

- "Call to action on sanitation" (PDF). United Nations. Archived from the original (PDF) on 19 August 2014. Retrieved 15 August 2014.

- Walker, CL; Rudan, I; Liu, L; Nair, H; Theodoratou, E; Bhutta, ZA; O'Brien, KL; Campbell, H; Black, RE (20 April 2013). "Global burden of childhood pneumonia and diarrhoea". Lancet. 381 (9875): 1405–16. doi:10.1016/s0140-6736(13)60222-6. PMC 7159282. PMID 23582727.

- Understanding Viruses. Jones & Bartlett Publishers. 2016. p. 456. ISBN 9781284025927.

- Communicable Disease Epidemiology and Control: A Global Perspective. CABI. 2005. p. 52. ISBN 9780851990743.

- François Brikké (2003). Linking technology choice with operation and maintenance in the context of community water supply and sanitation (PDF). World Health Organization. p. 108. ISBN 9241562153. Archived (PDF) from the original on 5 November 2005.

- Selendy, Janine M. H. (2011). Water and sanitation-related diseases and the environment challenges, interventions, and preventive measures. Hoboken, N.J.: Wiley-Blackwell. p. 25. ISBN 978-1-118-14860-0. Archived from the original on 8 March 2017.

- "Progress on Drinking Water, Sanitation and Hygiene: 2017 Update and SDG Baselines". UNICEF. United Nations Children's Fund (UNICEF), World Health Organization (WHO). 2017. Retrieved 20 September 2018.

- Sanjai, P (30 July 2018). "World's Biggest Toilet-Building Spree Is Under Way in India". www.bloomberg.com. Retrieved 20 September 2018.

- "Restructuring of the Nirmal Bharat Abhiyan into Swachh Bharat Mission". pib.nic.in. Retrieved 20 September 2018.

- "A Clean (Sampoorna Swachh) India". www.unicef.org. Retrieved 8 May 2022.

- "3 Years Of Swachh Bharat: 50 Million More Toilets; Unclear How Many Are Used". Fact Checker. 2 October 2017. Retrieved 20 September 2018.

- "Swachh Bharat Mission - Gramin, Ministry of Drinking Water and Sanitation". swachhbharatmission.gov.in. Retrieved 20 September 2018.

- Global Problems, Smart Solutions: Costs and Benefits. Cambridge University Press. 2013. p. 623. ISBN 978-1-107-43524-7.

- Stopnitzky, Yaniv (12 December 2011). "Haryana's scarce women tell potential suitors: "No loo, no I do"". Development Impact. Blog of World Bank. Archived from the original on 1 March 2015. Retrieved 17 November 2014.

- WHO and UNICEF definitions of improved drinking-water source on the JMP website, WHO, Geneva and UNICEF, New York, accessed on 16 December 2015

- DVGW (2006) Guidelines on drinking water protection areas – Part 1: Groundwater protection areas Archived 29 October 2014 at the Wayback Machine. Bonn, Deutsche Vereinigung des Gas- und Wasserfaches e.V. Technical rule number W101:2006-06

- Nick, A., Foppen, J. W., Kulabako, R., Lo, D., Samwel, M., Wagner, F., Wolf, L. (2012). Sustainable sanitation and groundwater protection – Factsheet of Working Group 11 Archived 27 October 2014 at the Wayback Machine. Sustainable Sanitation Alliance (SuSanA)

- ARGOSS (2001). Guidelines for assessing the risk to groundwater from on-site sanitation Archived 23 October 2014 at the Wayback Machine. NERC, British Geological Survey Commissioned Report, CR/01/142, UK

- Moore, C., Nokes, C., Loe, B., Close, M., Pang, L., Smith, V., Osbaldiston, S. (2010) Guidelines for separation distances based on virus transport between on-site domestic wastewater systems and wells, Porirua, New Zealand Archived 13 January 2015 at the Wayback Machine, p. 296

- Wolf, L., Nick, A., Cronin, A. (2015). How to keep your groundwater drinkable: Safer siting of sanitation systems Archived 2 April 2015 at the Wayback Machine – Working Group 11 Publication. Sustainable Sanitation Alliance

- Buitenkamp, M., Richert Stintzing, A. (2008). Europe's sanitation problem – 20 million Europeans need access to safe and affordable sanitation Archived 23 October 2014 at the Wayback Machine. Women in Europe for a Common Future (WECF), The Netherlands

- Rieck, C., von Münch, E., Hoffmann, H. (2012). Technology review of urine-diverting dry toilets (UDDTs) – Overview on design, management, maintenance and costs Archived 16 March 2016 at the Wayback Machine. Deutsche Gesellschaft fuer Internationale Zusammenarbeit (GIZ) GmbH, Eschborn, Germany

- "Single Ventilated Improved Pit - Akvopedia". akvopedia.org. Retrieved 21 May 2020.

This article incorporates text available under the CC BY 3.0 license.

This article incorporates text available under the CC BY 3.0 license. - Ahmed, M.F. & Rahman, M.M. (2003). Water Supply & Sanitation: Rural and Low Income Urban Communities, 2nd Edition, ITN-Bangladesh. ISBN 984-31-0936-8.

- sbmgramin (5 February 2018). "Why twin pit toilets?". Swachh Bharat (Grameen). Retrieved 8 May 2022.

- "The Toilet Papers". thewalrus.ca. 14 May 2014. Archived from the original on 11 March 2016. Retrieved 10 March 2016.

- American Standard (7 March 2013), Flush for Good: American Standard's Sanitary Toilet Pan Tested in Bangladesh, archived from the original on 16 May 2015, retrieved 10 March 2016

- "This $1.85 toilet could save millions of lives". Quartz. 26 September 2014. Archived from the original on 20 December 2015. Retrieved 10 March 2016.

- Still, David; Foxon, Kitty (2012). Tackling the challenges of full pit latrines : report to the Water Research Commission. Gezina [South Africa]: Water Research Commission. ISBN 978-1-4312-0293-5. Archived from the original on 24 September 2015.

- Balasubramanya, Soumya; Evans, Barbara; Ahmed, Rizwan; Habib, Ahasan; Asad, N. S. M.; Vuong, Luan; Rahman, Mominur; Hasan, Mahmudul; Dey, Digbijoy (1 September 2016). "Pump it up: making single-pit emptying safer in rural Bangladesh". Journal of Water Sanitation and Hygiene for Development. 6 (3): 456–464. doi:10.2166/washdev.2016.049. ISSN 2043-9083. Archived from the original on 18 August 2017.

- Balasubramanya, Soumya; Evans, Barbara; Ahmed, Rizwan; Habib, Ahasan; Asad, N. S. M.; Rahman, Mominur; Hasan, Mahmudul; Dey, Digbijoy; Camargo-Valero, Miller (1 March 2017). "Take it away: the need for designing fecal sludge disposal services for single-pit latrines". Journal of Water Sanitation and Hygiene for Development. 7 (1): 121–128. doi:10.2166/washdev.2017.073. ISSN 2043-9083. Archived from the original on 18 August 2017.

- Bakare, BF; Brouckaert, CJ; Foxon, KM; Buckley, CA (2015). "An investigation of the effect of pit latrine additives on VIP latrine sludge content under laboratory and field trials". Water SA. 41 (4): 509. doi:10.4314/wsa.v41i4.10. ISSN 0378-4738.

- Foxon, K., Still, D. (2012). Do pit additives work? Archived 13 February 2015 at the Wayback Machine Water Research Commission (WRC), University of KwaZulu-Natal, Partners in Development (PiD), South Africa

- WHO, UNICEF (2009). Diarrhoea : why children are still dying and what can be done (PDF). New York: United Nations Children's Fund. p. 2. ISBN 978-92-806-4462-3. Archived (PDF) from the original on 19 October 2013.

- McIntyre, P.; Casella D.; Fonseca, C.; Burr, P. Priceless! Uncovering the real costs of water and sanitation (PDF). The Hague: IRC. ISBN 978-90-6687-082-6. Archived (PDF) from the original on 13 March 2016. Retrieved 22 May 2016.

- Clasen, Thomas; Boisson, Sophie; Routray, Parimita; Torondel, Belen; Bell, Melissa; Cumming, Oliver; Ensink, Jeroen; Freeman, Matthew; Jenkins, Marion; Odagiri, Mitsunori; Ray, Subhajyoti; Sinha, Antara; Suar, Mrutyunjay; Schmidt, Wolf-Peter (2014). "Effectiveness of a rural sanitation programme on diarrhoea, soil-transmitted helminth infection, and child malnutrition in Odisha, India: a cluster-randomised trial" (PDF). The Lancet Global Health. 2 (11): e645-53. doi:10.1016/S2214-109X(14)70307-9. PMID 25442689.

External links

- Single pit latrine on eCompendium website, the online version of the Eawag-Sandec Compendium

- WEDC knowledge database filtered for WEDC guide and latrine (WEDC, Loughborough University, UK)

- Photos of pit latrines: Search for "pit latrine" in the Sustainable Sanitation Alliance photo database on flickr

- Storage and Treatments On-site storage and treatment technologies in Sustainable Sanitation and Water Management (SSWM) toolbox