Production schedule inputs:

- A good purchased as a "raw material" goes into the manufacture of a product.

- A good only partially completed during the manufacturing process is called "work in process. "

- When the good is completed as to manufacturing but not yet sold or distributed to the end user, it is called a "finished good. "

Raw materials - materials and components scheduled for use in making a product.

A raw material is the basic material from which a product is manufactured or made, frequently used with an extended meaning. For example, the term is used to denote material that came from nature and is in an unprocessed or minimally processed state. Latex, iron ore, logs, and crude oil, and salt water are examples. The use of raw material by non-human species includes twigs and found objects as used by birds to make nests.

Work in process, WIP - materials and components that have begun their transformation to finished goods.

Work in process (WIP) or in-process inventory includes the set at large of unfinished items for products in a production process. These items are not yet completed but either just being fabricated or waiting in a queue for further processing or in a buffer storage. The term is used in production and supply chain management.

Optimal production management aims to minimize work in process. Work in process requires storage space, represents bound capital not available for investment, and carries an inherent risk of earlier expiration of shelf life of the products. A queue leading to a production step shows that the step is well buffered for shortage in supplies from preceding steps, but may also indicate insufficient capacity to process the output from these preceding steps.

Finished goods - goods ready for sale to customers.

Finished goods are goods that have completed the manufacturing process but have not yet been sold or distributed to the end user. Finished goods is a relative term. In a Supply chain management flow, the finished goods of a supplier can constitute the raw material of a buyer.

Goods for resale - returned goods that are salable.

Inventory management

Inventory management is primarily about specifying the shape and percentage of stocked goods. It is required at different locations within a facility or within many locations of a supply network to precede the regular and planned course of production and stock of materials.

The scope of inventory management concerns the fine lines between replenishment lead time, carrying costs of inventory, asset management, inventory forecasting, inventory valuation, inventory visibility, future inventory price forecasting, physical inventory, available physical space for inventory, quality management, replenishment, returns and defective goods, and demand forecasting. Balancing these competing requirements leads to optimal inventory levels, which is an on-going process as the business needs shift and react to the wider environment.

Inventory management involves a retailer seeking to acquire and maintain a proper merchandise assortment while ordering, shipping, handling, and related costs are kept in check. It also involves systems and processes that identify inventory requirements, set targets, provide replenishment techniques, report actual and projected inventory status, and handle all functions related to the tracking and management of material. This would include the monitoring of material moved into and out of stockroom locations and the reconciling of the inventory balances. It also may include ABC analysis, lot tracking, cycle counting support, etc. Management of the inventories, with the primary objective of determining/controlling stock levels within the physical distribution system, functions to balance the need for product availability against the need for minimizing stock holding and handling costs.

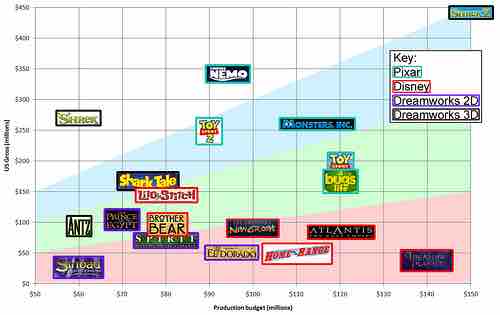

Production budget

Production budget is important for inventory and sales revenue

There are three basic reasons for keeping an inventory:

- Time: The time lags present in the supply chain, from supplier to user at every stage, requires that you maintain certain amounts of inventory to use in this lead time. However, in practice, inventory is to be maintained for consumption during variations in lead time. Lead time itself can be addressed by ordering that many days in advance.

- Uncertainty: Inventories are maintained as buffers to meet uncertainties in demand, supply and movements of goods.

- Economies of scale: Ideal condition of "one unit at a time at a place where a user needs it, when he needs it" principle tends to incur lots of costs in terms of logistics. So bulk buying, movement, and storing brings in economies of scale, thus inventory.

A Sample Production Plan

An example of a production plan covering one week.