Polyhydroxyalkanoates, or PHAs, are linear polyesters produced in nature by bacterial fermentation of sugar or lipids. They are produced by the bacteria to store carbon and energy. More than 150 different monomers can be combined within this family to give materials extremely diverse properties. These plastics are biodegradeable and are used in the production of bioplastics. They can be either thermoplastic or elastomeric materials, with melting points ranging from 40 to 180 °C.

The mechanical qualities and biocompatibility of PHA can also be changed by blending, modifying the surface or combining PHA with other polymers, enzymes and inorganic materials, making it possible for a wider range of applications.

PROCESS OF PHA PRODUCTION

To produce PHA, a culture of a micro-organism such as Alcaligenes eutrophus is placed in a suitable medium and fed appropriate nutrients so that it multiplies rapidly. The biosynthesis of PHA is usually caused by certain deficiency conditions (e.g. lack of macro elements such as phosphorus, nitrogen, trace elements, or lack of oxygen) and the excess supply of carbon sources. Recombinants Bacillus subtilis str. pBE2C1 and Bacillus subtilis str. pBE2C1AB were used in production of polyhydroxyalkanoates (PHA) and it was shown that they could use malt waste as carbon source for lower cost of PHA production. As raw material for the fermentation, carbohydrates such as glucose and sucrose can be used, but also vegetable oil or glycerine from biodiesel production. Researchers in the industry are working on methods with which transgenic crops will be developed that express PHA synthesis routes from bacteria and so produce PHA as energy storage in their tissues. Another group of researchers at Micromidas is working to develop methods of producing PHA from municipal waste water. Another even larger scale synthesis can be done with the help of soil organisms. For lack of nitrogen and phosphorus they produce a kilogram of PHA from three kilograms of sugar.

Polyesters are deposited in the form of highly refractive granules in the cells. Depending upon the microorganism and the cultivation conditions, homo- or copolyesters with different hydroxyalkanic acids are generated. PHAs granules are then recovered by disrupting the cells. In the industrial production of PHA, the polyester is extracted and purified from the bacteria by optimizing the conditions of microbial fermentation of sugar or glucose. Once the population has reached a substantial level, the nutrient composition is changed to force the micro-organism to synthesize PHA. The yield of PHA obtained from the intracellular inclusions can be as high as 80% of the organism's dry weight .

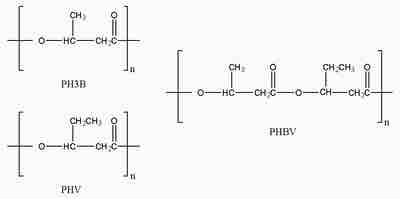

Chemical structures of P3HB, PHV and their copolymer PHBV

Chemical structures of P3HB, PHV and their copolymer PHBV

PHA SYNTHASES

PHA synthases are the key enzymes of PHA biosynthesis. They use the coenzyme A - thioester of (r)-hydroxy fatty acids as substrates. The two classes of PHA synthases differ in the specific use of hydroxyfattyacids of short or medium chain length. The resulting PHA is of the two types: Poly (HA SCL) from hydroxy fatty acids with short chain lengths including three to five carbon atoms are synthesized by numerous bacteria, including Ralstonia eutropha and Alcaligenes latus (PHB). Poly (HA MCL) from hydroxy fatty acids with middle chain lengths including six to 14 carbon atoms, can be made for example, by Pseudomonas putida. A few bacteria, including Aeromonas hydrophila and Thiococcus pfennigii, synthesize copolyester from the above two types of hydroxy fatty acids. The simplest and most commonly occurring form of PHA is the fermentative production of poly-beta-hydroxybutyrate) (poly-3-hydroxybutyrate, P3HB), which consists of 1000 to 30000 hydroxy fatty acid monomers.

PHA APPLICATIONS

PHAs are processed mainly via injection molding, extrusion and extrusion bubbles into films and hollow bodies. A PHA copolymer called PHBV (poly(3-hydroxybutyrate-co-3-hydroxyvalerate)) is less stiff and tougher, and it may be used as packaging material. There are also applications for PHA produced by micro-organisms within the medical and pharmaceutical industries, primarily due to their biodegradability. Some of the fixation and orthopaedic applications that have been devised for these polymers include:

- sutures and suture fasteners

- meniscus repair and regeneration devices

- rivets, tacks, staples, and screws

- bone plates and bone plating systems

- surgical mesh, repair patches, and cardiovascular patches

- vein valves, bone marrow scaffolds

- ligament and tendon grafts

- ocular cell implants

- skin substitutes, bone graft substitutes, and wound dressings