Introduction

Decision makers complete five steps when making a business buying decision:

- Recognize the problem

- Develop product specifications to solve the problem

- Search for and evaluate possible products and suppliers

- Select product and supplier and order product

- Evaluate product and supplier performance

Vendor performance measurement plays a role in Steps 3 and 5.

Step 3: Search for and Evaluate Possible Products and Suppliers

Step 3 requires searching for and evaluating possible products and suppliers. This can be done in several ways:

- Looking in company files and trade directories, contacting suppliers for information, soliciting proposals from known vendors, and examining websites, catalogs and trade publications.

- Performing a value analysis (an evaluation of each component of a potential purchase). This examines the quality, design, and materials, with the intention of finding cost savings opportunities.

- Performing a vendor analysis (a formal, systematic evaluation of current and potential vendors). This focuses on price, quality, service, availability, and overall reliability.

Step 5: Evaluate Product and Supplier Performance

Step 5 of the business buying decision process involves evaluating product and supplier performance.

Firms need to compare products with specifications. The results become feedback for other stages in future business purchasing decisions. If a firm has any negative issues with a vendor, it is likely they will look for another one.

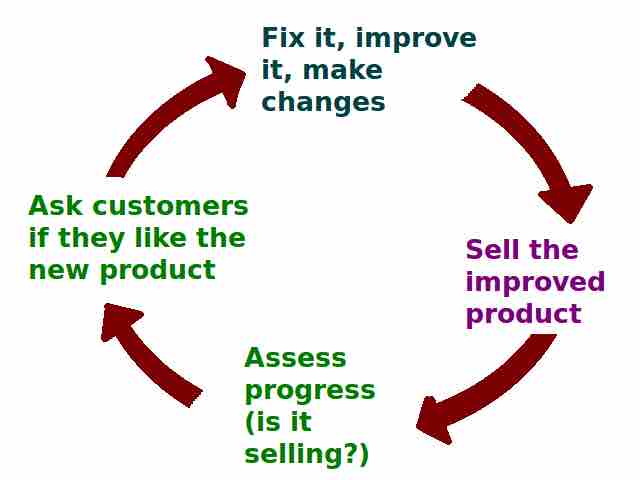

Business Feedback loop

Firms need to compare products with specifications. The results become feedback for other stages in future business purchasing decisions. If a firm has any negative issues with a vendor, it is likely they will look for another one.

Supplier performance evaluation teams are used to monitor activity and performance data, and to rate vendors. But supplier performance evaluation teams are just one of the many teams companies deploy to address tactical issues.

Supplier certification teams help selected suppliers reach desired levels of quality, reduce costs, and improve service. Specification teams select and write functional, technical, and process requirements for goods and services to be acquired.

Supply managers evaluate suppliers utilizing the tools of value assessment and the fundamental value equation. They estimate the benefits and total costs paid to each vendor. Consistent with supply management orientation, these evaluations can be complemented with the firm's customer feedback. In this way, supply managers can better focus or redirect the efforts of the entire supply network toward the delivery of superior value to end-users.