FFP standards

EN 149 is a European standard of testing and marking requirements for filtering half masks.[1] Such masks cover the nose, mouth and chin and may have inhalation and/or exhalation valves.[1] EN 149 defines three classes of such particle half masks, called FFP1, FFP2 and FFP3, (where FFP stands for filtering facepiece)[2] according to their filtering efficiency. It also classifies masks into "single shift use only" (not re-usable, marked NR) or "re-usable (more than one shift)" (marked R), and an additional marking letter D indicates that a mask has passed an optional clogging test using dolomite dust. Such mechanical filter respirators protect against the inhalation of particulates such as dust particles, droplets, and aerosols.[3]

Almost identical tests (but different markings) are used in Australia, New Zealand, Korea and Brazil. Similar standards are used in the United States, China and Japan. For example, EN 149 FFP2 masks have similar performance requirements to N95 masks in the United States and KN95 filters of China, and EN 149 FFP3 masks have similar performance requirements to N99 masks in the United States. However EN 149 test requirements differ somewhat from the U.S./Chinese/Japanese standards: EN 149 requires an additional paraffin oil (paraffinum perliquidum) aerosol test and it tests at a range of different flow rates and defines several associated and permissible pressure drop levels.[4][5]

Classification

The EN 149 standard defines performance requirements for three classes of particle-filtering half masks: FFP1, FFP2 and FFP3. The protection provided by an FFP2 (or FFP3) mask includes the protection provided by a mask of the lower-numbered classes.

A mask conforming to the standard must have its class written on it, along with the name of the standard and its year of publication, as well as any applicable option codes, e.g. “EN 149:2001 FFP1 NR D”. Some manufacturers use in addition the colour of the elastic band to identify the mask class, however, the EN 149 standard does not specify any such colour coding and different manufacturers have used different colour schemes.

| Class[6] | Filter penetration limit (at 95 L/min air flow) | Inward leakage | Typical elastic band |

|---|---|---|---|

| FFP1 | Filters at least 80% of airborne particles | <22% | Yellow |

| FFP2 | Filters at least 94% of airborne particles | <8% | Blue or White |

| FFP3 | Filters at least 99% of airborne particles | <2% | Red |

FFP1 mask

.jpg.webp)

It is the least filtering mask of the three.

- Aerosol filtration percentage: 80% minimum.

- Internal leak rate: maximum 22%.[6]

It is mainly used as a dust mask (for example for DIY jobs). Dust can cause lung diseases, such as silicosis, anthracosis, siderosis and asbestosis (in particular dust from silica, coal, iron ore, zinc, aluminium or cement are common particulate risks).

FFP2 mask

.jpg.webp)

- Aerosol filtration percentage: 94% minimum.

- Internal leak rate: maximum 8%.[6]

This mask offers protection in various areas such as the glass industry, foundry, construction, pharmaceutical industry and agriculture. It effectively stops powdered chemicals. This mask can also serve as protection against respiratory viruses such as avian influenza or severe acute respiratory syndrome associated with the coronavirus (SARS), as well as against the bacteria of pneumonic plague and tuberculosis.[7] It is similar to the US-standard N95 respirator.[4]

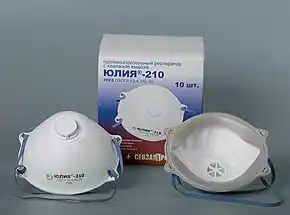

FFP3 mask

.jpg.webp)

- Aerosol filtration percentage: 99% minimum.

- Internal leak rate: maximum 2%[6]

The FFP3 mask is the most filtering of the FFP masks. It protects against very fine particles such as asbestos and ceramic. It does not protect against gases and in particular oxides of nitrogen.[8]

Requirements

EN 149 defines laboratory tests, field tests and certain requirements to ensure the conformity of the masks. The following points are analyzed:

- Packaging

- Materials: resistance to manipulation

- Practical performance test

- Leakage: total leakage inwards and penetration of the filter material

There are some European organizations that issue an examination certificate confirming conformity and specifying the characteristics of the products:

- INRS then APAVE in France

- INSPEC in Great Britain

- FACHAUSSCHUSS in Germany

- Institute for Occupational Safety and Health of the German Social Accident Insurance[9] in Germany

- CIOP-PIB in Poland [10]

2009 version

With the publication of the 2009 version of the standard, the designation of the respiratory protection mask is now "particulate filtering half mask". The abbreviation NR or R is added after FFP1, FFP2, FFP3:

- NR (not reusable): if the use of the filtering half-face mask is limited to one working day. It is not reusable.

- R (reusable): if the filtering half-face mask can be used for more than one working day, so it is reusable.

Additional suffixes include:

- Anti-clogging NR masks (D). When the half mask has passed the dolomite dust test, a letter D can be added to indicate that the service life may exceed 8 h.[11] Example: FFP3 NR D.

- Valve. The presence of a valve can be indicated by the letter V.[12]

- Particulate type. The letters S or L respectively specify the filtration of solid dust (NaCl-only) or liquid mist (paraffin oil). Example: FFP3 SLV.[13]

Masks manufactured before the new standard was taken into account may still have the old marking.

Marking

FFP respirators are a type of personal protective equipment (PPE). Here is the notice that should appear on every mask :

- Manufacturer's name

- Mask

- CE number of the certification body (only FFP3) + EN 149: 2009 + the mask class (FFP1, FFP2 or FFP3) + acronym (NR or R) (Note: in case of FFP1 the conformity assessment procedures are done by the manufacturer itself as per Annex IV (Module A)

The marking must comply with European Union Directive 89/686 / EEC[6] on PPE. If any of these entries are missing, the mask will be considered non-compliant.

Medical use

EN 149 tests the ability of masks to protect the wearers against inhaling liquid and dry aerosols. It makes no statement about, and does not specifically test the suitability of such masks for, infection control against airborne transmission of pathogens through respiratory droplets. Nevertheless, FFP2 and FFP3 masks are commonly used for this purpose in medical practice. An NHS study published in 2021 claimed switching to FFP3 "may have cut ward-based infection to zero".[14]

Similar standards

Several regions use standards based on nearly identical tests and thresholds as those in EN 149, but with different markings:[4]

- Russia (GOST R 12.4.191-2011): identical.

- South Korea (KMOEL - 2017–64): considered identical to pre-2009 version. FFP1 is called "2nd grade" or KF80, FFP2 "1st grade" or KF94, and FFP3 "special grade" or KF99.[15]

- Australia and New Zealand (AS/NZ 1716:2012): similar grades with a different test agent. Grades are written simply "P".

- Brazil (ABNT/NBR 13698:2011): identical to pre-2009 version. Grades are written as "PFF".[16]

Other regions use similar tests that (in parts) resemble more closely the 42 CFR 84 requirements in the United States:

- Japan (JMHLW-Notification 214, 2018): similar grades with a different coding scheme for NR/R and S/L types. Written with a two-letter prefix D/R and S/L that maps to NR/R and S/L respectively. Leakage requirement not present.[17]

- Taiwan (CNS 14755): D1/D2/D3 grades for 80/95/99 efficiency. No requirements for inward leakage.

See also

Notes and references

- 1 2 Respiratory protective devices – Filtering half masks to protect against particles – Requirements, testing, marking, European Committee for Standardization (CEN), May 2009, EN 149:2001+A1:2009 (E)

- ↑

- ↑ "WIP-Richtlijn Persoonlijke beschermingsmiddelen [ZKH]" (PDF). rivm.nl. Werkgroep Infectie Preventie, RIVM. September 2015. Retrieved 2020-04-30.

- 1 2 3 "Comparison of FFP2, KN95, and N95 and Other Filtering Facepiece Respirator Classes" (PDF). 3M Technical Data Bulletin. 2020-01-01. Retrieved 2020-03-28.

- ↑ "Strategies for Optimizing the Supply of N95 Respirators: Crisis/Alternate Strategies". U.S. Centers for Disease Control and Prevention. 2020-03-17. Retrieved 2020-03-28.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain. - 1 2 3 4 5 "Fiche pratique de sécurité ED 105. Appareils de protection respiratoire et métiers de la santé" (PDF). inrs.fr. INRS. Retrieved 7 April 2020.

- ↑ "Risques infectieux en milieu de soins - masques médicaux ou appareils de protection respiratoire jetables : quel matériel choisir ?". sante.gouv.fr. 27 August 2009. Retrieved 16 June 2015.

- ↑ "Vélib' et pollution, les réponses du docteur Jean-Luc Saladin". Archived from the original on 17 September 2014. Retrieved 1 June 2015.

- ↑ European Commission. "Notification". Retrieved 2021-02-19.

- ↑ CIOP-PIB. "Department of Personal Protective Equipment".

- ↑ MOLDEX-METRIC. "La série 3000 FFP" (PDF).

- ↑ "2016 Catalogue" (PDF). VENUS Safety & Health Pvt. Ltd. Archived from the original (PDF) on 2020-02-27. Retrieved 2020-04-08.

- ↑ "BLS Zer0 30 FFP3 Carbon Valved Face Mask". AES Industrial Supplies Limited. Retrieved 2021-02-19.

- ↑ Nicola Davis; Denis Campbell (June 29, 2021). "Cambridge hospital's mask upgrade appears to eliminate Covid risk to staff Hospital: infection study shows use of FFP3 respirators at Addenbrooke's 'may have cut ward-based infection to zero'". The Guardian. Retrieved June 29, 2021.

“Once FFP3 respirators were introduced, the number of cases attributed to exposure on Covid-19 wards dropped dramatically – in fact, our model suggests that FFP3 respirators may have cut ward-based infection to zero.”

- ↑ Jung, Hyejung; Kim, Jongbo; Lee, Seungju; Lee, Jinho; Kim, Jooyoun; Tsai, Perngjy; Yoon, Chungsik (2014). "Comparison of Filtration Efficiency and Pressure Drop in Anti-Yellow Sand Masks, Quarantine Masks, Medical Masks, General Masks, and Handkerchiefs". Aerosol and Air Quality Research. 14 (3): 991–1002. doi:10.4209/aaqr.2013.06.0201.

- ↑ "ABNT/NBR 13698:2011 E quip amento de proteção respiratória — Peça semifacial fi ltrante para partículas" (PDF) (in Brazilian Portuguese).

- ↑ "Standard for Dust Mask". JICOSH Home.