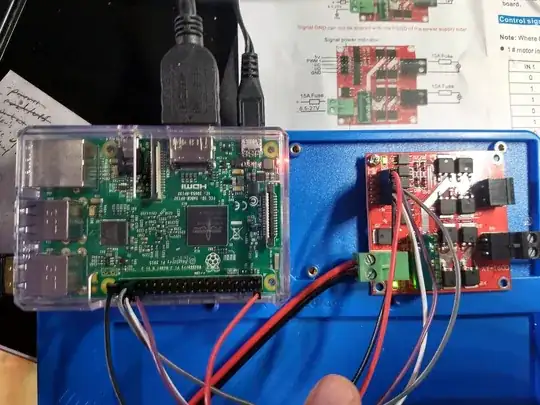

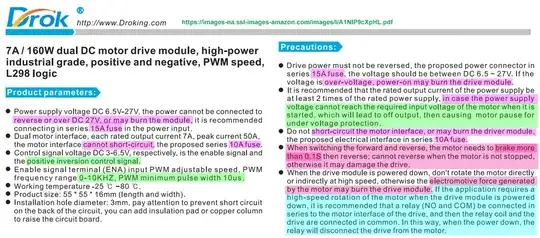

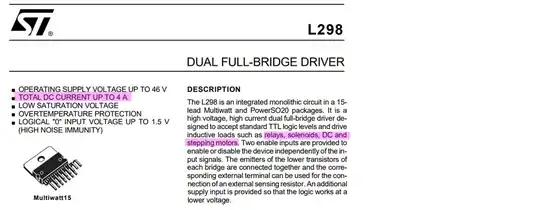

I bought two DROK L298 H-Bridges to control my DC motor (one for backup). I've connected it up to my Raspberry Pi 3 with BCM 12 as my PWM and 16 and 19 as my IN1 and IN2. Below is my code to test if the motor works - but it doesn't turn.

I tested the code on an L293D chip which turns the motor and tested both L298 H-bridges with no success. Looking for thoughts on how to get the motor working on the L298 H-bridge.

import RPi.GPIO as GPIO

import time

MotorPin1 = 16 # pin36

MotorPin2 = 19 # pin35

MotorEnable = 12 # pin32

GPIO.setmode(GPIO.BCM) # Numbers GPIOs by BCM

GPIO.setup(MotorPin1, GPIO.OUT) # mode --- output

GPIO.setup(MotorPin2, GPIO.OUT)

GPIO.setup(MotorEnable, GPIO.OUT)

GPIO.output(MotorEnable, GPIO.LOW) # motor stop

pwm = GPIO.PWM(MotorEnable, 1) # configuring Enable pin (MotorEnable) for PWM)

pwm.start(50) #starting pwm with 50% duty cycle

print 'Press Ctrl+C to end the program...'

print 'Raising...'

GPIO.output(MotorPin1, GPIO.HIGH) # clockwise

GPIO.output(MotorPin2, GPIO.LOW)

GPIO.output(MotorEnable, GPIO.HIGH) # motor driver enable

time.sleep(2.5)

GPIO.output(MotorEnable, GPIO.LOW) # motor stop

time.sleep(0.5)

print 'Dropping...'

pwm.ChangeDutyCycle(20) #decreasing dutycycle to 20

GPIO.output(MotorPin1, GPIO.LOW) # counter-clockwise

GPIO.output(MotorPin2, GPIO.HIGH)

GPIO.output(MotorEnable, GPIO.HIGH) # motor driver enable

time.sleep(1.5)

GPIO.output(MotorEnable, GPIO.LOW) # motor stop

time.sleep(0.5)

pwm.stop()

GPIO.cleanup() # Release resource

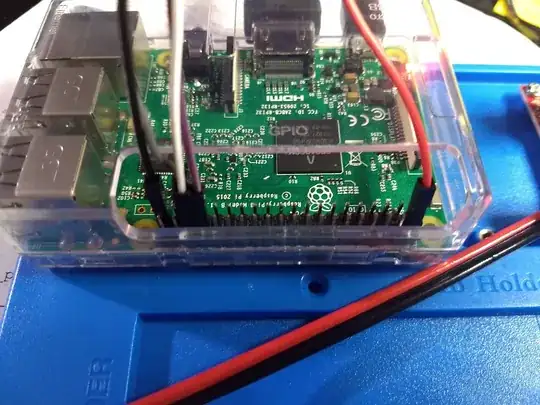

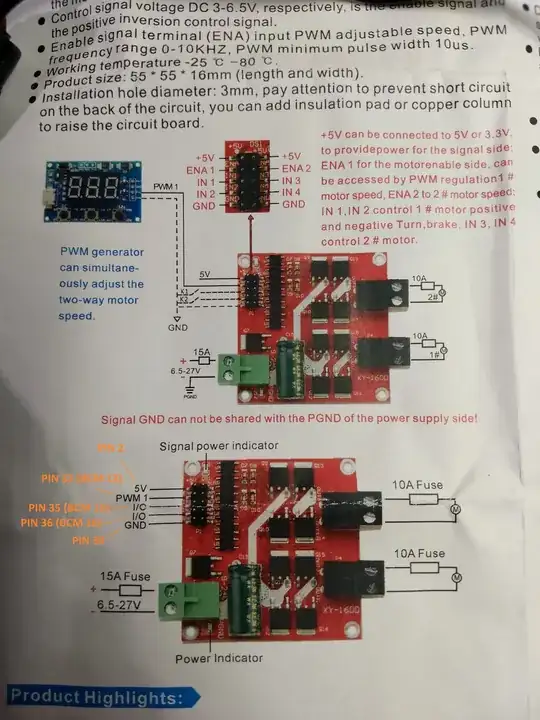

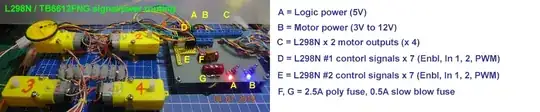

- Update * Pictures of the spec sheet & connections

- Update 2 - Realized GPIO 12 was in the wrong pin. Changed it to the correct one (5th up) but still no motor turning.