Mitre box

A mitre box or miter box (American English) is a wood working appliance used to guide a hand saw for making precise cuts, usually 45° mitre cuts.[1][2] Traditional mitre boxes are simple in construction and made of wood, while adjustable mitre boxes are made of metal and can be adjusted for cutting any angle from 45° to 90°.

A simple wooden mitre box for cutting 45° and 90° angles | |

| Other names | Miter box |

|---|---|

| Classification | Woodworking appliance |

| Used with | A backsaw |

| Related | Powered mitre saw |

In many workshops and jobsites mitre boxes have been superseded by the powered mitre saw, however advocates for mitre boxes argue that they are more accurate, safer, quieter, cheaper, and take up less space than a powered mitre saw.[3]

Description

Basic mitre box

The most common and simplest form of a mitre box is a U-shaped block made from wood, plastic or aluminium, which is open at the top and the ends. The box is made wide enough to accommodate the width of the workpieces to be cut. Slots are cut in the walls of the box at the precise angle at which the cut is to be made. These slots provide the guide for the saw to follow. Most commonly, the slots in the mitre box are cut at 45° and 90° angles.

While wooden mitre boxes are mass produced, being simple in construction they are often made by woodworkers themselves from three pieces of wood screwed or glued together. The slots are then cut using the same saw that will be used with the box.[4]

Wooden mitre boxes have a limited lifespan, as over time the saw wears away the sides and bottoms of the slots, reducing the accuracy of cuts. Some mitre boxes are fitted with guides across the top of the box to reduce wear on the slots and to provide rigidity to the box.[5]

Mitre boxes can also be purpose-made by the woodworker for cutting angles other than 45° or for cutting compound (sloped) angles, or they can be designed for securing a particular size of workpiece.[6]

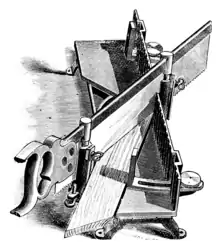

Adjustable mitre box

An adjustable mitre box is designed for cutting any angle from 45° to 90° degrees. Made of metal, they consist of a base, a fence, and a mechanism for supporting a backsaw at the set angle. The workpiece is held against the fence while the saw is used. Historically a mitre saw is a type of backsaw with a wide blade designed for use with an adjustable mitre box, however the term is now more commonly used to refer to a powered mitre saw, which is a successor of the adjustable mitre box.[1]: 425

Use

As well as pieces of wood for use in joinery, the mitre box also sees common use in workshops and on jobsites for cutting various types of moulding. For precise work, a workpiece cut in a mitre box might then be further refined using a hand plane and shooting board.

Basic mitre box

The workpiece is placed in the box and the point at which the board is to be cut is lined up with the appropriate slot in the sides of the mitre box. The workpiece is then held or clamped in place. Backsaws are the most common hand saw used with mitre boxes, but other types of hand saw are also used. The saw is placed between the slots before sawing.

Adjustable mitre box

The workpiece is aligned with the saw and held or clamped against the fence. Depending on the mitre box design, the cut is then made with either a dedicated mitre saw, or another suitable saw that can fit between the guides.

See also

References

- Salaman, R. A. (1975). Dictionary of tools used in the woodworking and allied trades, c. 1700-1970. Internet Archive. New York: Scribner. pp. 278–279, 425. ISBN 978-0-684-14535-8.

- "mitre | miter, n.2". Oxford English Dictionary. Retrieved 2020-11-10.

- Schwarz, Christopher (2010). The Anarchist's Tool Chest. Fort Mitchell, Kentucky, USA: Lost Art Press LLC. pp. 41, 286–287. ISBN 978-0-578-08413-8. OCLC 875304703.

- Hayward, Charles H. How to Make Woodworking Tools (PDF). London: Evans Brothers Limited. pp. 41–42.

- Wearing, Robert (1985). Making woodwork aids & devices (Revised ed.). New York: Sterling Publishing Co., Inc. p. 79. ISBN 0-8069-6264-X. OCLC 12160958.

- Blackburn, Graham (2014). Jigs & fixtures for the hand tool woodworker. Cincinnati, Ohio: Popular Woodworking Books. p. 79. ISBN 978-1-4403-3340-8. OCLC 866616892.