Polyvinyl chloride

| |

| |

| |

| Names | |

|---|---|

| IUPAC name

poly(1-chloroethene)[1] | |

| Other names

Polychloroethene | |

| Identifiers | |

| Abbreviations | PVC |

| ChEBI | |

| ChemSpider |

|

| ECHA InfoCard | 100.120.191 |

| KEGG | |

| MeSH | Polyvinyl+Chloride |

CompTox Dashboard (EPA) |

|

| Properties | |

| (C2H3Cl)n[2] | |

| Appearance | white, brittle solid |

| Odor | odorless |

| Density | 1.4 g/cm3 |

| insoluble | |

| Solubility in ethanol | insoluble |

| Solubility in tetrahydrofuran | slightly soluble |

| −10.71×10−6 (SI, 22 °C)[3] | |

| Hazards | |

| NFPA 704 (fire diamond) | |

Threshold limit value (TLV) |

10 mg/m3 (inhalable), 3 mg/m3 (respirable) (TWA) |

| NIOSH (US health exposure limits):[4] | |

PEL (Permissible) |

15 mg/m3 (inhalable), 5 mg/m3 (respirable) (TWA) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

Infobox references | |

| Elongation at break | 20–40% |

|---|---|

| Notch test | 2–5 kJ/m2 |

| Glass Transition Temperature | 82 °C (180 °F)[5] |

| Melting point | 100 °C (212 °F) to 260 °C (500 °F)[5] |

| Effective heat of combustion | 17.95 MJ/kg |

| Specific heat (c) | 0.9 kJ/(kg·K) |

| Water absorption (ASTM) | 0.04–0.4 |

| Dielectric Breakdown Voltage | 40 MV/m |

Polyvinyl chloride (alternatively: poly(vinyl chloride),[6][7] colloquial: polyvinyl, or simply vinyl;[8] abbreviated: PVC) is the world's third-most widely produced synthetic polymer of plastic (after polyethylene and polypropylene).[9] About 40 million tons of PVC are produced each year.

PVC comes in rigid (sometimes abbreviated as RPVC) and flexible forms. Rigid PVC is used in construction for pipe, doors and windows. It is also used in making plastic bottles, packaging, and bank or membership cards. Adding plasticizers makes PVC softer and more flexible. It is used in plumbing, electrical cable insulation, flooring, signage, phonograph records, inflatable products, and in rubber substitutes.[1][10] With cotton or linen, it is used in the production of canvas.

Polyvinyl chloride is a white, brittle solid. It is insoluble in all solvents but swells in the monomer and some chlorinated hydrocarbon solvents.

Discovery

PVC was synthesized in 1872 by German chemist Eugen Baumann after extended investigation and experimentation.[11] The polymer appeared as a white solid inside a flask of vinyl chloride that had been left on a shelf sheltered from sunlight for four weeks. In the early 20th century, the Russian chemist Ivan Ostromislensky and Fritz Klatte of the German chemical company Griesheim-Elektron both attempted to use PVC in commercial products, but difficulties in processing the rigid, sometimes brittle polymer thwarted their efforts. Waldo Semon and the B.F. Goodrich Company developed a method in 1926 to plasticize PVC by blending it with various additives,[12] including the use of dibutyl phthalate by 1933.[13]

Production

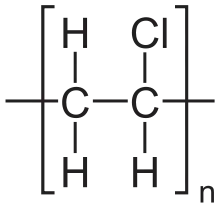

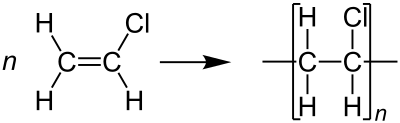

Polyvinyl chloride is produced by polymerization of the vinyl chloride monomer (VCM), as shown.[14]

|

About 80% of production involves suspension polymerization. Emulsion polymerization accounts for about 12%, and bulk polymerization accounts for 8%. Suspension polymerization affords particles with average diameters of 100–180 μm, whereas emulsion polymerization gives much smaller particles of average size around 0.2 μm. VCM and water are introduced into the reactor along with a polymerization initiator and other additives. The contents of the reaction vessel are pressurized and continually mixed to maintain the suspension and ensure a uniform particle size of the PVC resin. The reaction is exothermic and thus requires cooling. As the volume is reduced during the reaction (PVC is denser than VCM), water is continually added to the mixture to maintain the suspension.[9]

PVC may be manufactured from either naphtha or ethylene feedstock.[15]

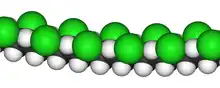

Microstructure

The polymers are linear and are strong. The monomers are mainly arranged head-to-tail, meaning that chloride is located on alternating carbon centres. PVC has mainly an atactic stereochemistry, which means that the relative stereochemistry of the chloride centres are random. Some degree of syndiotacticity of the chain gives a few percent crystallinity that is influential on the properties of the material. About 57% of the mass of PVC is chlorine. The presence of chloride groups gives the polymer very different properties from the structurally related material polyethylene.[16] At 1.4 g/cm3, PVC's density is also higher than for these structurally related plastics such as polyethylene (0.88–0.96 g/cm3) and polymethylmethacrylate (1.18 g/cm3).

Producers

About half of the world's PVC production capacity is in China, despite the closure of many Chinese PVC plants due to issues complying with environmental regulations and poor capacities of scale. The largest single producer of PVC as of 2018 is Shin-Etsu Chemical of Japan, with a global share of around 30%.[15]

Additives

The product of the polymerization process is unmodified PVC. Before PVC can be made into finished products, it always requires conversion into a compound by the incorporation of additives (but not necessarily all of the following) such as heat stabilizers, UV stabilizers, plasticizers, processing aids, impact modifiers, thermal modifiers, fillers, flame retardants, biocides, blowing agents and smoke suppressors, and, optionally, pigments.[17] The choice of additives used for the PVC finished product is controlled by the cost performance requirements of the end use specification (underground pipe, window frames, intravenous tubing and flooring all have very different ingredients to suit their performance requirements). Previously, polychlorinated biphenyls (PCBs) were added to certain PVC products as flame retardants and stabilizers.[18]

Plasticizers

Among the common plastics, PVC is unique in its acceptance of large amounts of plasticizer with gradual changes in physical properties from a rigid solid to a soft gel,[19] and almost 90% of all plasticizer production is used in making flexible PVC.[20][21] The majority is used in films and cable sheathing.[22] Flexible PVC can consist of over 85% plasticizer by mass, however unplasticized PVC (UPVC) should not contain any.[23]

A wide variety of substances can be used as plasticizers including phthalates, organophosphates, adipates, trimellitates, polymeric plasticizers and epoxidized vegetable oils.[24]

| Plasticizer content (% DINP by weight) | Specific gravity (20 °C) | Shore hardness (type A, 15 s) | Flexural stiffness (Mpa) | Tensile strength (Mpa) | Elongation at break (%) | Example applications | |

|---|---|---|---|---|---|---|---|

| Rigid | 0 | 1.4 | 900 | 41 | <15 | Unplasticized PVC (UPVC): window frames and sills, doors, rigid pipe | |

| Semi-rigid | 25 | 1.26 | 94 | 69 | 31 | 225 | Vinyl flooring, flexible pipe, thin films (stretch wrap), advertising banners |

| Flexible | 33 | 1.22 | 84 | 12 | 21 | 295 | Wire and cable insulation, flexible pipe |

| Very Flexible | 44 | 1.17 | 66 | 3.4 | 14 | 400 | Boots and clothing, inflatables, |

| Extremely Flexible | 86 | 1.02 | < 10 | Fishing lures (soft plastic bait), polymer clay, plastisol inks |

Phthalates

The most common class of plasticizers used in PVC is phthalates, which are diesters of phthalic acid. Phthalates can be categorized as high and low, depending on their molecular weight. Low phthalates such as Bis(2-ethylhexyl) phthalate (DEHP) and Dibutyl phthalate (DBP) have increased health risks and are generally being phased out. High-molecular-weight phthalates such as Diisononyl phthalate (DINP), Diisodecyl phthalate (DIDP) are generally considered safer[21]

While DEHP has been medically approved for many years for use in medical devices, it was permanently banned for use in children's products in the US in 2008 by US Congress;[25] the PVC-DEHP combination had proved to be very suitable for making blood bags because DEHP stabilizes red blood cells, minimizing hemolysis (red blood cell rupture). However, DEHP is coming under increasing pressure in Europe. The assessment of potential risks related to phthalates, and in particular the use of DEHP in PVC medical devices, was subject to scientific and policy review by the European Union authorities, and on 21 March 2010, a specific labeling requirement was introduced across the EU for all devices containing phthalates that are classified as CMR (carcinogenic, mutagenic or toxic to reproduction).[26] The label aims to enable healthcare professionals to use this equipment safely, and, where needed, take appropriate precautionary measures for patients at risk of over-exposure[27]

phthalate.svg.png.webp)

Metal stabilizers

BaZn stabilisers have successfully replaced cadmium-based stabilisers in Europe in many PVC semi-rigid and flexible applications.[28]

In Europe, particularly Belgium, there has been a commitment to eliminate the use of cadmium (previously used as a part component of heat stabilizers in window profiles) and phase out lead-based heat stabilizers (as used in pipe and profile areas) such as liquid autodiachromate and calcium polyhydrocummate by 2015. According to the final report of Vinyl 2010,[29] cadmium was eliminated across Europe by 2007. The progressive substitution of lead-based stabilizers is also confirmed in the same document showing a reduction of 75% since 2000 and ongoing. This is confirmed by the corresponding growth in calcium-based stabilizers, used as an alternative to lead-based stabilizers, more and more, also outside Europe.

Heat stabilizers

Some of the most crucial additives are heat stabilizers. These agents minimize loss of HCl, a degradation process that starts above 70 °C (158 °F). starts, it is autocatalytic. Many diverse agents have been used including, traditionally, derivatives of heavy metals (lead, cadmium). Metallic soaps (metal "salts" of fatty acids) are common in flexible PVC applications, species such as calcium stearate.[9]

Properties

PVC is a thermoplastic polymer.[30] Its properties are usually categorized based on rigid and flexible PVCs.[31]

| Property | Unit of measurement | Rigid PVC | Flexible PVC |

|---|---|---|---|

| Density[32] | g/cm3 | 1.3–1.45 | 1.1–1.35 |

| Thermal conductivity[33] | W/(m·K) | 0.14–0.28 | 0.14–0.17 |

| Yield strength[32] | psi | 4,500–8,700 | 1,450–3,600 |

| MPa | 31–60 | 10.0–24.8 | |

| Young's modulus[34] | psi | 490,000 | — |

| GPa | 3.4 | — | |

| Flexural strength (yield)[34] | psi | 10,500 | — |

| MPa | 72 | — | |

| Compression strength[34] | psi | 9,500 | — |

| MPa | 66 | — | |

| Coefficient of thermal expansion (linear)[34] | mm/(mm °C) | 5×10−5 | — |

| Vicat B[33] | °C | 65–100 | Not recommended |

| Resistivity[lower-alpha 1][35] | Ω m | 1016 | 1012–1015 |

| Surface resistivity[lower-alpha 1][35] | Ω | 1013–1014 | 1011–1012 |

- Notes

- At 60% relative humidity and room temperature.

Thermal and fire

The heat stability of raw PVC is very poor, so the addition of a heat stabilizer during the process is necessary in order to ensure the product's properties. Traditional product PVC has a maximum operating temperature around 60 °C (140 °F) when heat distortion begins to occur.[36]

As a thermoplastic, PVC has an inherent insulation that aids in reducing condensation formation and resisting internal temperature changes for hot and cold liquids.[36]

Applications

.jpg.webp)

Pipes

Roughly half of the world's PVC resin manufactured annually is used for producing pipes for municipal and industrial applications.[37] In the private homeowner market, it accounts for 66% of the household market in the US, and in household sanitary sewer pipe applications, it accounts for 75%.[38][39] Buried PVC pipes in both water and sanitary sewer applications that are 100 mm (4 in) in diameter and larger are typically joined by means of a gasket-sealed joint. The most common type of gasket utilized in North America is a metal-reinforced elastomer, commonly referred to as a Rieber sealing system.[40]

Electric cables

In a fire, PVC-coated wires can form hydrogen chloride fumes; the chlorine serves to scavenge free radicals and is the source of the material's fire retardancy. While hydrogen chloride fumes can also pose a health hazard in their own right, it dissolves in moisture and breaks down onto surfaces, particularly in areas where the air is cool enough to breathe, and is not available for inhalation.[41]

Construction

PVC is used in construction because it is more effective than traditional materials, such as copper, iron or wood in pipe manufacturing.[1] It is extensively used in the building industry as a low-maintenance material, particularly in Ireland, the United Kingdom, the United States, and Canada. In the US and Canada, it is known as vinyl or vinyl siding.[42] The material comes in a range of colors and finishes, including a photo-effect wood finish, and is used as a substitute for painted wood, mostly for window frames and sills when installing insulated glazing in new buildings; or to replace older single-glazed windows, as it does not decompose and is weather-resistant. Other uses include fascia, and siding or weatherboarding. This material has almost entirely replaced the use of cast iron for plumbing and drainage, being used for waste pipes, drainpipes, gutters and downspouts. PVC is known as having strong resistance against chemicals, sunlight, and oxidation from water.[43]

Signs

Polyvinyl chloride is formed in flat sheets in a variety of thicknesses and colors. As flat sheets, PVC is often expanded to create voids in the interior of the material, providing additional thickness without additional weight and minimal extra cost (see closed-cell PVC foamboard). Sheets are cut using saws and rotary cutting equipment. Plasticized PVC is also used to produce thin, colored, or clear, adhesive-backed films referred to simply as vinyl. These films are typically cut on a computer-controlled plotter (see vinyl cutter) or printed in a wide-format printer. These sheets and films are used to produce a wide variety of commercial signage products, including car body stripes and stickers.[44]

Clothing

PVC fabric is water-resistant, used for its weather-resistant qualities in coats, skiing equipment, shoes, jackets, and aprons.

Healthcare

The two main application areas for single-use medically approved PVC compounds are flexible containers and tubing: containers used for blood and blood components, for urine collection or for ostomy products and tubing used for blood taking and blood giving sets, catheters, heart-lung bypass sets, hemodialysis sets etc. In Europe the consumption of PVC for medical devices is approximately 85,000 tons each year. Almost one third of plastic-based medical devices are made from PVC.[45]

Wire rope

PVC may be extruded under pressure to encase wire rope and aircraft cable used for general purpose applications. PVC coated wire rope is easier to handle, resists corrosion and abrasion, and may be color-coded for increased visibility. It is found in a variety of industries and environments both indoor and out.[46]

Other uses

PVC piping is cheaper than metals used in musical instrument making; it is therefore a common alternative when making instruments, often for leisure or for rarer instruments such as the contrabass flute. An instrument that is almost exclusively built from PVC tube is the thongophone, a percussion instrument that is played by slapping the open tubes with a flip-flop or similar.[47] PVC is used as a raw material in automotive underbody coating.[48]

Chlorinated PVC

PVC can be usefully modified by chlorination, which increases its chlorine content to or above 67%. Chlorinated polyvinyl chloride, (CPVC), as it is called, is produced by chlorination of aqueous solution of suspension PVC particles followed by exposure to UV light which initiates the free-radical chlorination.[9]

Health and safety

Degradation

The fungus Aspergillus fumigatus degrades plasticized PVC.[49] Phanerochaete chrysosporium was grown on PVC in a mineral salt agar.[50] Phanerochaete chrysosporium, Lentinus tigrinus, Aspergillus niger, and Aspergillus sydowii can effectively degrade PVC.[51]

Plasticizers

Phthalates, which are incorporated into plastics as plasticizers, comprise approximately 70% of the US plasticizer market; phthalates are by design not covalently bound to the polymer matrix, which makes them highly susceptible to leaching. Phthalates are contained in plastics at high percentages. For example, they can contribute up to 40% by weight to intravenous medical bags and up to 80% by weight in medical tubing.[52] Vinyl products are pervasive—including toys,[53] car interiors, shower curtains, and flooring—and initially release chemical gases into the air. Some studies indicate that this outgassing of additives may contribute to health complications, and have resulted in a call for banning the use of DEHP on shower curtains, among other uses.[54]

In 2004 a joint Swedish-Danish research team found a statistical association between allergies in children and indoor air levels of DEHP and BBzP (butyl benzyl phthalate), which is used in vinyl flooring.[55] In December 2006, the European Chemicals Bureau of the European Commission released a final draft risk assessment of BBzP which found "no concern" for consumer exposure including exposure to children.[56]

Lead

Lead had previously been frequently added to PVC to improve workability and stability. Lead has been shown to leach into drinking water from PVC pipes.[57]

In Europe the use of lead-based stabilizers was gradually replaced. The VinylPlus voluntary commitment which began in 2000, saw European Stabiliser Producers Association (ESPA) members complete the replacement of Pb-based stabilisers in 2015.[58][59]

Vinyl chloride monomer

In the early 1970s, the carcinogenicity of vinyl chloride (usually called vinyl chloride monomer or VCM) was linked to cancers in workers in the polyvinyl chloride industry. Specifically workers in polymerization section of a B.F. Goodrich plant near Louisville, Kentucky, were diagnosed with liver angiosarcoma also known as hemangiosarcoma, a rare disease.[60] Since that time, studies of PVC workers in Australia, Italy, Germany, and the UK have all associated certain types of occupational cancers with exposure to vinyl chloride, and it has become accepted that VCM is a carcinogen.[9]

Dioxins

PVC produces HCl upon combustion almost quantitatively related to its chlorine content. Extensive studies in Europe indicate that the chlorine found in emitted dioxins is not derived from HCl in the flue gases. Instead, most dioxins arise in the condensed solid phase by the reaction of inorganic chlorides with graphitic structures in char-containing ash particles. Copper acts as a catalyst for these reactions.[61]

Studies of household waste burning indicate consistent increases in dioxin generation with increasing PVC concentrations.[62] According to the EPA dioxin inventory, landfill fires are likely to represent an even larger source of dioxin to the environment. A survey of international studies consistently identifies high dioxin concentrations in areas affected by open waste burning and a study that looked at the homologue pattern found the sample with the highest dioxin concentration was "typical for the pyrolysis of PVC". Other EU studies indicate that PVC likely "accounts for the overwhelming majority of chlorine that is available for dioxin formation during landfill fires."[62]

The next largest sources of dioxin in the EPA inventory are medical and municipal waste incinerators.[63] Various studies have been conducted that reach contradictory results. For instance a study of commercial-scale incinerators showed no relationship between the PVC content of the waste and dioxin emissions.[64][65] Other studies have shown a clear correlation between dioxin formation and chloride content and indicate that PVC is a significant contributor to the formation of both dioxin and PCB in incinerators.[66][67][68]

In February 2007, the Technical and Scientific Advisory Committee of the US Green Building Council (USGBC) released its report on a PVC avoidance related materials credit for the LEED Green Building Rating system. The report concludes that "no single material shows up as the best across all the human health and environmental impact categories, nor as the worst" but that the "risk of dioxin emissions puts PVC consistently among the worst materials for human health impacts."[69]

In Europe the overwhelming importance of combustion conditions on dioxin formation has been established by numerous researchers. The single most important factor in forming dioxin-like compounds is the temperature of the combustion gases. Oxygen concentration also plays a major role on dioxin formation, but not the chlorine content.[70]

Several studies have also shown that removing PVC from waste would not significantly reduce the quantity of dioxins emitted. The EU Commission published in July 2000 a Green Paper on the Environmental Issues of PVC"[71]

A study commissioned by the European Commission on "Life Cycle Assessment of PVC and of principal competing materials" states that "Recent studies show that the presence of PVC has no significant effect on the amount of dioxins released through incineration of plastic waste."[72]

End-of-life

The European waste hierarchy refers to the five steps included in the article 4 of the Waste Framework Directive:[73]

- Prevention: preventing and reducing waste generation.

- Reuse and preparation for reuse: giving the products a second life before they become waste.

- Recycle: any recovery operation by which waste materials are reprocessed into products, materials or substances whether for the original or other purposes. It includes composting and it does not include incineration.

- Recovery: some waste incineration based on a political non-scientific formula.

- Refuse: throwing it into a landfill. [74]

Industry initiatives

In Europe, developments in PVC waste management have been monitored by Vinyl 2010,[75] established in 2000. Vinyl 2010's objective was to recycle 200,000 tonnes of post-consumer PVC waste per year in Europe by the end of 2010, excluding waste streams already subject to other or more specific legislation (such as the European Directives on End-of-Life Vehicles, Packaging and Waste Electric and Electronic Equipment).

Since June 2011, it is followed by VinylPlus, a new set of targets for sustainable development.[76] Its main target is to recycle 800,000 tonnes per year of PVC by 2020 including 100,000 tonnes of "difficult to recycle" waste. One facilitator for collection and recycling of PVC waste is Recovinyl.[77] The reported and audited mechanically recycled PVC tonnage in 2016 was 568,695 tonnes which in 2018 had increased to 739,525 tonnes.[78]

One approach to address the problem of waste PVC is also through the process called Vinyloop. It is a mechanical recycling process using a solvent to separate PVC from other materials. This solvent turns in a closed loop process in which the solvent is recycled. Recycled PVC is used in place of virgin PVC in various applications: coatings for swimming pools, shoe soles, hoses, diaphragms tunnel, coated fabrics, PVC sheets.[79] This recycled PVC's primary energy demand is 46 percent lower than conventional produced PVC. So the use of recycled material leads to a significant better ecological footprint. The global warming potential is 39 percent lower.[80]

Restrictions

In November 2005, one of the largest hospital networks in the US, Catholic Healthcare West, signed a contract with B. Braun Melsungen for vinyl-free intravenous bags and tubing.[81]

In January 2012, a major US West Coast healthcare provider, Kaiser Permanente, announced that it will no longer buy intravenous (IV) medical equipment made with PVC and DEHP-type plasticizers.[82]

In 1998, the U.S. Consumer Product Safety Commission (CPSC) arrived at a voluntary agreement with manufacturers to remove phthalates from PVC rattles, teethers, baby bottle nipples and pacifiers.[83]

Vinyl gloves in medicine

Plasticized PVC is a common material for medical gloves. Due to vinyl gloves having less flexibility and elasticity, several guidelines recommend either latex or nitrile gloves for clinical care and procedures that require manual dexterity and/or that involve patient contact for more than a brief period. Vinyl gloves show poor resistance to many chemicals, including glutaraldehyde-based products and alcohols used in formulation of disinfectants for swabbing down work surfaces or in hand rubs. The additives in PVC are also known to cause skin reactions such as allergic contact dermatitis. These are for example the antioxidant bisphenol A, the biocide benzisothiazolinone, propylene glycol/adipate polyester and ethylhexylmaleate.[84]

Sustainability

PVC is made from fossil fuels, including natural gas. The production process also uses sodium chloride which results in a polymer containing 57% chloride content. Recycled PVC is broken down into small chips, impurities removed, and the product refined to make pure PVC.[44]

In Europe, a 2021 VinylPlus Progress Report indicated that 731,461 tonnes PVC were recycled in 2020, a 5% reduction compared to 2019 due to the COVID-19 pandemic. The report also covers all five sustainability challenges that the sector has set for itself covering controlled loop management, organochlorine emissions, sustainable use of additives, sustainable use of energy and raw materials and sustainability awareness.[85]

There is also a continuing focus on the role that the polymer plays in meeting the Circular Economy model and contribution to Sustainable Development Goals. The Olympic Delivery Authority (ODA), for example, after initially rejecting PVC as material for different temporary venues of the London Olympics 2012, has reviewed its decision and developed a policy for its use.[86] This policy highlighted that the functional properties of PVC make it the most appropriate material in certain circumstances while taking into consideration the environmental and social impacts across the whole life cycle, e.g. the rate for recycling or reuse and the percentage of recycled content. Temporary parts, like roofing covers of the Olympic Stadium, the Water Polo Arena, and the Royal Artillery Barracks, would be deconstructed and a part recycled in the VinyLoop process.[87][88]

See also

References

General references

- Titow, W. (1984). PVC Technology. London: Elsevier Applied Science Publishers. ISBN 978-0-85334-249-6.

Inline citations

- "poly(vinyl chloride) (CHEBI:53243)". CHEBI. Archived from the original on 13 December 2013. Retrieved 12 July 2012.

- "Substance Details CAS Registry Number: 9002-86-2". Commonchemistry. CAS. Archived from the original on 21 May 2018. Retrieved 12 July 2012.

- Wapler, M. C.; Leupold, J.; Dragonu, I.; von Elverfeldt, D.; Zaitsev, M.; Wallrabe, U. (2014). "Magnetic properties of materials for MR engineering, micro-MR and beyond". JMR. 242: 233–242. arXiv:1403.4760. Bibcode:2014JMagR.242..233W. doi:10.1016/j.jmr.2014.02.005. PMID 24705364. S2CID 11545416.

- "Material Safety Data Sheet: PVC Compounds Pellet and Powder" (PDF). Georgia Gulf Chemical and Vinyls LLC. Archived (PDF) from the original on 17 August 2021. Retrieved 23 July 2021.

- Wilkes, Charles E.; Summers, James W.; Daniels, Charles Anthony; Berard, Mark T. (2005). PVC Handbook. Hanser Verlag. p. 414. ISBN 978-1-56990-379-7. Archived from the original on 17 November 2016. Retrieved 24 September 2016.

- "Poly(vinyl chloride)". MilliporeSigma. 2022. Archived from the original on 11 October 2022. Retrieved 11 October 2022.

- "Poly(Vinyl Chloride)".

- "What is PVC" Archived 18 July 2017 at the Wayback Machine- Retrieved 11 July 2017

- Allsopp, M. W.; Vianello, G. (2012). "Poly(Vinyl Chloride)". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a21_717.

- W. V. Titow (31 December 1984). PVC technology. Springer. pp. 6–. ISBN 978-0-85334-249-6. Archived from the original on 26 May 2013. Retrieved 6 October 2011.

- Baumann, E. (1872) "Ueber einige Vinylverbindungen" Archived 17 November 2016 at the Wayback Machine (On some vinyl compounds), Annalen der Chemie und Pharmacie, 163 : 308–322.

- Semon, Waldo L.; Stahl, G. Allan (April 1981). "History of Vinyl Chloride Polymers". Journal of Macromolecular Science: Part A - Chemistry. 15 (6): 1263–1278. doi:10.1080/00222338108066464.

- US 1929453, Waldo Semon, "Synthetic rubber-like composition and method of making same", published 1933-10-10, assigned to B.F. Goodrich

- Chanda, Manas; Roy, Salil K. (2006). Plastics technology handbook. CRC Press. pp. 1–6. ISBN 978-0-8493-7039-7.

- "Shin-Etsu Chemical to build $1.4bn polyvinyl chloride plant in US". Nikkei Asian Review. Archived from the original on 24 July 2018. Retrieved 24 July 2018.

- Handbook of Plastics, Elastomers, and Composites, Fourth Edition, 2002 by The McGraw-Hill, Charles A. Harper Editor-in-Chief. ISBN 0-07-138476-6

- David F. Cadogan and Christopher J. Howick "Plasticizers" in Ullmann's Encyclopedia of Industrial Chemistry 2000, Wiley-VCH, Weinheim. doi:10.1002/14356007.a20_439

- Karlen, Kaley. "Health Concerns and Environmental Issues with PVC-Containing Building Materials in Green Buildings" (PDF). Integrated Waste Management Board. California Environmental Protection Agency, US. Archived (PDF) from the original on 5 February 2016. Retrieved 26 August 2015.

- Krauskopf, Leonard G. (2009). "3.13 Plasticizers". Plastics additives handbook (6. ed.). Munich: Carl Hanser Verlag. pp. 485–511. ISBN 978-3-446-40801-2.

- David F. Cadogan and Christopher J. Howick "Plasticizers" in Ullmann's Encyclopedia of Industrial Chemistry 2000, Wiley-VCH, Weinheim. doi:10.1002/14356007.a20_439

- "factsheets - Plasticisers - Information Center". Plasticisers. Archived from the original on 9 February 2022. Retrieved 19 February 2022.

- "Plasticizers Market Report". Ceresana. Retrieved 7 January 2023.

- Krauskopf, L. G. (2009). Plastics additives handbook (6. ed.). Munich: Carl Hanser Verlag. p. 495. ISBN 978-3-446-40801-2.

- "Home - Plasticisers - Information Center". Plasticisers. Archived from the original on 8 February 2022. Retrieved 19 February 2022.

- "Phthalates and DEHP". Health Care Without Harm. 29 April 2013. Retrieved 23 July 2021.

- Opinion on The safety of medical devices containing DEHP plasticized PVC or other plasticizers on neonates and other groups possibly at risk (2015 update) Archived 3 February 2016 at the Wayback Machine. Scientific Committee on Emerging and Newly-Identified Health Risks (25 June 2015).

- "You searched for DEHP - Plasticisers - Information Center". Plasticisers. Archived from the original on 9 February 2022. Retrieved 19 February 2022.

- Liquid stabilisers. Seuropean Stabiliser Producers Association

- Vinyl 2010. The European PVC Industry's Sustainable Development Programme

- "Polyvinyl Chloride". ScienceDirect. Archived from the original on 15 January 2021. Retrieved 30 July 2022.

- "DIFFERENCES BETWEEN FLEXIBLE AND RIGID PVC COMPOUNDS". Green PVC. 12 August 2021. Archived from the original on 16 December 2021.

- Titow 1984, p. 1186.

- Titow 1984, p. 1191.

- Titow 1984, p. 857.

- Titow 1984, p. 1194.

- Michael A. Joyce, Michael D. Joyce (2004). Residential Construction Academy: Plumbing. Cengage Learning. pp. 63–64.

- Rahman, Shah (19–20 June 2007). PVC Pipe & Fittings: Underground Solutions for Water and Sewer Systems in North America (PDF). 2nd Brazilian PVC Congress, Sao Paulo, Brazil. Archived from the original (PDF) on 9 July 2015. Retrieved 28 February 2009.

- Uses for vinyl: pipe. vinylbydesign.com

- Rahman, Shah (October 2004). "Thermoplastics at Work: A Comprehensive Review of Municipal PVC Piping Products" (PDF). Underground Construction: 56–61. Archived from the original on 7 August 2020. Retrieved 5 February 2019.

- Shah Rahman (April 2007). "Sealing Our Buried Lifelines" (PDF). American Water Works Association (AWWA) OPFLOW Magazine: 12–17. Archived (PDF) from the original on 8 October 2011. Retrieved 30 March 2010.

- Galloway FM, Hirschler MM, Smith GF (1992). "Surface parameters from small-scale experiments used for measuring HCl transport and decay in fire atmospheres". Fire Mater. 15 (4): 181–189. doi:10.1002/fam.810150405.

- PolyVinyl (Poly Vinyl Chloride) in Construction Archived 31 August 2006 at the Wayback Machine. Azom.com (26 October 2001). Retrieved on 6 October 2011.

- Strong, A. Brent (2005) Plastics: Materials and Processing. Prentice Hall. pp. 36–37, 68–72. ISBN 0131145584.

- Ellis, R. "Vinyl: an Honest Conversation". Archived from the original on 28 January 2021. Retrieved 3 June 2020.

- PVC Healthcare Applications. pvcmed.org

- "Coated Aircraft Cable & Wire Rope". Lexco Cable. Archived from the original on 26 August 2017. Retrieved 25 August 2017.

- Building a PVC Instrument. natetrue.com

- Takata, Ayumi; Ohashi, Yutaka (2002). "Post PVC Sound Insulating Underbody coating". SAE Technical Paper Series. Vol. 1. doi:10.4271/2002-01-0293.

- Ishtiaq Ali, Muhammad (2011). Microbial degradation of polyvinyl chloride plastics (PDF) (PhD). Quaid-i-Azam University. pp. 45–46. Archived from the original (PDF) on 24 December 2013. Retrieved 13 May 2016.

- Ishtiaq Ali, Muhammad (2011). Microbial degradation of polyvinyl chloride plastics (PDF) (PhD). Quaid-i-Azam University. p. 76. Archived from the original (PDF) on 24 December 2013. Retrieved 23 December 2013.

- Ishtiaq Ali, Muhammad (2011). Microbial degradation of polyvinyl chloride plastics (PDF) (PhD). Quaid-i-Azam University. p. 122. Archived from the original (PDF) on 30 January 2016.

- Halden, Rolf U. (2010). "Plastics and Health Risks". Annual Review of Public Health. 31: 179–194. doi:10.1146/annurev.publhealth.012809.103714. PMID 20070188.

- Directive 2005/84/EC of the European Parliament and of the Council 14 December 2005 Archived 4 May 2013 at the Wayback Machine. Official Journal of the European Union. 27 December 2005

- Vinyl shower curtains a 'volatile' hazard, study says Archived 4 September 2010 at the Wayback Machine. Canada.com (12 June 2008). Retrieved on 6 October 2011.

- Bornehag, Carl-Gustaf; Sundell, Jan; Weschler, Charles J.; Sigsgaard, Torben; Lundgren, Björn; Hasselgren, Mikael; Hägerhed-Engman, Linda; et al. (2004). "The Association between Asthma and Allergic Symptoms in Children and Phthalates in House Dust: A Nested Case–Control Study". Environmental Health Perspectives. 112 (14): 1393–1397. doi:10.1289/ehp.7187. PMC 1247566. PMID 15471731.

- Phthalate Information Center Blog: More good news from Europe. phthalates.org (3 January 2007)

- "China's PVC pipe makers under pressure to give up lead stabilizers". 6 September 2013.

- "Lead replacement". European Stabiliser Producers Association. Archived from the original on 5 December 2018. Retrieved 5 December 2018.

- "VinylPlus Progress Report 2016" (PDF). VinylPlus. 30 April 2016. Archived (PDF) from the original on 20 December 2016.

- Creech, J. L. Jr.; Johnson, M. N. (March 1974). "Angiosarcoma of liver in the manufacture of polyvinyl chloride". Journal of Occupational Medicine. 16 (3): 150–1. PMID 4856325.

- Steiglitz, L., and Vogg, H. (February 1988) "Formation Decomposition of Polychlorodibenzodioxins and Furans in Municipal Waste" Report KFK4379, Laboratorium fur Isotopentechnik, Institut for Heize Chemi, Kerforschungszentrum Karlsruhe.

- Costner, Pat (2005) "Estimating Releases and Prioritizing Sources in the Context of the Stockholm Convention" Archived 27 September 2007 at the Wayback Machine, International POPs Elimination Network, Mexico.

- Beychok, M.R. (1987). "A data base of dioxin and furan emissions from municipal refuse incinerators". Atmospheric Environment. 21 (1): 29–36. Bibcode:1987AtmEn..21...29B. doi:10.1016/0004-6981(87)90267-8.

- National Renewable Energy Laboratory, Polyvinyl Chloride Plastics in Municipal Solid Waste Combustion Archived 15 February 2013 at the Wayback Machine NREL/TP-430- 5518, Golden CO, April 1993

- Rigo, H. G.; Chandler, A. J.; Lanier, W.S. (1995). The Relationship between Chlorine in Waste Streams and Dioxin Emissions from Waste Combustor Stacks (PDF). ISBN 978-0-7918-1222-8. Archived from the original (PDF) on 7 April 2016. Retrieved 31 October 2009.

{{cite book}}:|journal=ignored (help) - Katami, Takeo; Yasuhara, Akio; Okuda, Toshikazu; Shibamoto, Takayuki; et al. (2002). "Formation of PCDDs, PCDFs, and Coplanar PCBs from Polyvinyl Chloride during Combustion in an Incinerator". Environ. Sci. Technol. 36 (6): 1320–1324. Bibcode:2002EnST...36.1320K. doi:10.1021/es0109904. PMID 11944687.

- Wagner, J.; Green, A. (1993). "Correlation of chlorinated organic compound emissions from incineration with chlorinated organic input". Chemosphere. 26 (11): 2039–2054. Bibcode:1993Chmsp..26.2039W. doi:10.1016/0045-6535(93)90030-9.

- Thornton, Joe (2002). Environmental Impacts of polyvinyl Chloride Building Materials (PDF). Washington, DC: Healthy Building Network. ISBN 978-0-9724632-0-1. Archived from the original (PDF) on 20 September 2013. Retrieved 6 October 2011.

- The USGBC document Archived 13 July 2007 at the Wayback Machine; An analysis by the Healthy Building NEtwork Archived 2 June 2008 at the Wayback Machine

- Wikstrom, Evalena; G. Lofvenius; C. Rappe; S. Marklund (1996). "Influence of Level and Form of Chlorine on the Formation of Chlorinated Dioxins, Dibenzofurans, and Benzenes during Combustion of an Artificial Fuel in a Laboratory Reactor". Environmental Science & Technology. 30 (5): 1637–1644. Bibcode:1996EnST...30.1637W. doi:10.1021/es9506364.

- Environmental issues of PVC Archived 12 May 2012 at the Wayback Machine. European Commission. Brussels, 26 July 2000

- Life Cycle Assessment of PVC and of principal competing materials Commissioned by the European Commission. European Commission (July 2004), p. 96

- Waste Hierarchy Archived 25 October 2017 at the Wayback Machine. Wtert.eu. Retrieved on 28 January 2016.

- "EUR-Lex – 32008L0098 – EN – EUR-Lex". eur-lex.europa.eu. 22 November 2008. Archived from the original on 20 September 2017. Retrieved 25 August 2017.

- Home – Vinyl 2010 The European PVC industry commitment to Sustainability Archived 25 July 2013 at the Wayback Machine. Vinyl2010.org (22 June 2011). Retrieved on 6 October 2011.

- Our Voluntary Commitment. vinylplus.eu

- Incentives to collect and recycle Archived 19 January 2022 at the Wayback Machine. Recovinyl.com. Retrieved on 28 January 2016.

- "VinylPlus Progress Report 2019" (PDF). Archived (PDF) from the original on 14 February 2020. Retrieved 22 September 2019.

- Solvay, asking more from chemistry Archived 1 January 2012 at the Wayback Machine. Solvayplastics.com (15 July 2013). Retrieved on 28 January 2016.

- Solvay, asking more from chemistry Archived 16 May 2016 at the Portuguese Web Archive. Solvayplastics.com (15 July 2013). Retrieved on 28 January 2016.

- "CHW Switches to PVC/DEHP-Free Products to Improve Patient Safety and Protect the Environment". Business Wire. 21 November 2005. Archived from the original on 9 April 2016. Retrieved 28 January 2016.

- Smock, Doug (19 January 2012) Kaiser Permanente bans PVC tubing and bags. plasticstoday.com

- "PVC Policies Across the World". chej.org. Archived from the original on 10 August 2017. Retrieved 25 August 2017.

- "Vinyl Gloves: Causes For Concern" (PDF). Ansell (glove manufacturer). Archived from the original (PDF) on 22 September 2015. Retrieved 17 November 2015.

- "VinylPlus at a Glance 2021 - VinylPlus". Vinylplus.eu. 17 May 2021. Archived from the original on 7 February 2022. Retrieved 19 February 2022.

- London 2012 Use of PVC Policy Archived 1 February 2016 at the Wayback Machine. independent.gov.uk.

- London 2012 Archived 1 February 2016 at the Wayback Machine. independent.gov.uk.

- Clark, Anthony (31 July 2012) PVC at Olympics destined for reuse or recycling Archived 3 February 2016 at the Wayback Machine. plasticsnews.com