Scouring (textiles)

Scouring is a preparatory treatment of certain textile materials. Scouring removes soluble and insoluble impurities found in textiles as natural, added and adventitious impurities, for example, oils, waxes, fats, vegetable matter, as well as dirt. Removing these contaminants through scouring prepares the textiles for subsequent processes such as bleaching and dyeing.[1]: 74–75 Though a general term, "scouring" is most often used for wool. In cotton, it is synonymously called "boiling out," and in silk, and "boiling off."[2]: 1 [3][4][5]: 78

Purpose of scouring

Scouring is an essential pre-treatment for the subsequent finishing stages that include bleaching, dyeing, and printing.[6]: 399 Raw and unfinished textiles contain a significant amount of impurities, both natural and foreign. It is necessary to eliminate these impurities to make the products ready for later steps in textile manufacturing.[2]: 1 For instance, fatty substances and waxy matters are the major barriers in the hydrophilicity of the natural fibers. Absorbency helps the penetration of chemicals in the stages such as dyeing and printing or finishing of the textiles.[7] These fats and waxy substances are converted into soluble salts with the help of alkali.[8] This treatment is called Saponification.[9]

Impurities

Foreign matter in addition to fiber is known as impurities. Textile fibers contain many types of impurities. e.g.:

- Natural impurities: Impurities gathered from the natural environment by the fibres. Natural impurities also include non-fibrous parts that are incorporated into the fiber during its growth. Notably, these are not present in synthetic fibres, which are manufactured artificially.

- Added: Oils and waxes during spinning or knitting or weaving.

- Accidental: dirt or mishandling, foreign contaminants.[10][11][12]

| Fiber type | Impurities in %age | Source |

|---|---|---|

| Wool | 40-50 | [5]: 78 |

| Cotton | 10 | [13] |

| Silk | 22-30 | [14] |

Etymology, and history

Etymology

The term "scouring" refers to the "act of cleaning with a rubbing action.''[15]

History

Textile manufacturing was once an everyday household activity.[16] In Europe, women were often involved in manufacturing manufacturing. They used to spin, weave, process, and finish the products they needed at home.[17][18][19] In the pre-industrial era, scouring (wool scouring) was a part of the fulling process of cloth making, in which the cloths were cleaned, and then milled (a thickening process). Fulling used to be done by pounding the woolen cloth with a club, or by the fuller's feet or hands. This process was associated with waulking songs, which were sung by women in the Scottish Gaelic tradition to set the pace.[20][21][22][23]

Earliest scouring agents

Scouring agents are the cleaning agents that remove the impurities from the textiles during the scouring process. While these are now industraialy-produced, scouring agents were once produced locally; lant or stale urine and lixivium, a solution of alkaline salts extracted from wood ashes, were among the earliest scouring agents. Lant, which contains ammonium carbonate, was used to scour the wool.[24][2]: 9

Wool scouring

The removal of lanolin, vegetable materials and other wool contaminants before use is an example of wool scouring.[25][26] Wool scouring is the next process after the woollen fleece of a sheep is cut off.[27] Raw wool is also known as ''Greasy wool.''

“Grease” or “yolk'' is a combined form of dried sweat, oil and fatty matter.[28] Lanolin is the major component (5-25%) of raw wool which is a waxy substance secreted by the sebaceous glands of wool-bearing animals.[29] Greasy matter varies by breed.[2]: 13 Following the cleaning process, the wool fibers possess a chemical composition of keratin.[30][5]: 1

Impurities in wool

| Type of impurity | In Merino, %age | In Crossbreed, in %age |

|---|---|---|

| Dirt or soil | 19 | 8 |

| Grease | 16 | 11 |

| Suint | 6 | 8 |

Process

Three steps comprise the complete cleaning process for wool: steeping, scouring, and rinsing.[31]

Steeping

Potash and wool fat are two beneficial substances among the contaminants in wool, necessitating the development of specific cleaning techniques capable of recovering these compounds. Steeping is an alternative scouring process, In steeping system, scouring entails in parts. Wool steeping is carried out in stages such as immersing it in lukewarm water for many hours.[32][33] When the wool includes only a little amount of yolk, the steeping method for recovering the yolk can be skipped.[34]

Scouring treatment

Scouring is the process of cleaning wool that makes it free from grease, perspiration residue ( "suint"), dead skin and dirt and vegetable matter present as impurities in the wool. It may consist of a simple boiling of wool in water or an industrial process of treating wool with alkalis and detergents (or soap and Sodium carbonate.)[35][2]: 1 [36] Bath temperature is maintained (at 65 degree Celsius) to melt wool grease.[37] (Lanolin melts at a temperature of 38-44 °C.)[38]

The next treatment is carbonization, a treatment with strong acids that convert vegetable matter into carbon.[39]

Rinsing

Rinsing is the process of thoroughly washing the cleaned wool.

Alternative method

The alternative method is solvent scouring.[2]: 61

Solvent method

Solvent scouring of wool replaces soap, detergent, and alkalies with a solvent liquid such as carbon tetrachloride, ether, petroleum naphtha, Chloroform, benzene, or carbon disulfide, etc. These liquids are capable of dissolving impurities but highly volatile and flammable. Hence, they need extra care in handling.[2]: 62

Gallery

Unscoured wool

Unscoured wool.jpg.webp) Qashqhaï women (nomadic shepperds) washing the just harvested wool. Sarab-e Bahram, Area of Noorabad, Fars, Iran, April 2007

Qashqhaï women (nomadic shepperds) washing the just harvested wool. Sarab-e Bahram, Area of Noorabad, Fars, Iran, April 2007 Wool scouring in the machine

Wool scouring in the machine Wool scouring in the machine, technician monitoring wool scouring process

Wool scouring in the machine, technician monitoring wool scouring process Scoured wool

Scoured wool

Cotton scouring

In cotton, non-cellulosic substances such as waxes, lipids, pectic substances, organic acids contribute to around ten percent of the weight.[13] Cotton, in particular, has fewer impurities than wool.[5]: 102 Cotton scouring refers to removing impurities such as natural wax, pectins, and non-fibrous matter with a wetting agent and caustic soda.[8]: 25 [4] In comparison, alkaline boiling has no effect on cellulose.[5]: 102

Impurities in cotton

Cotton Pectins, waxes, proteins, mineral compounds, and ash, etc.

| Type of impurity | %age |

|---|---|

| Pectins | 0.4-1.2 |

| Wax | 0.4-1.2 |

| Others | 1.7 |

Discontinuous scouring

In discontinuous method certain machines are used such as dyeing vessels, winches, jiggers and Kier.[3]: 19, 20 [8]: 51 [4]

Kier boiling

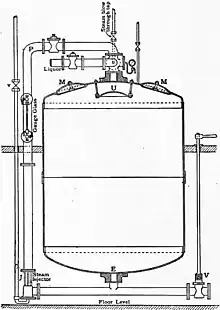

Kier is a large cylindrical vessel, upright, with egg shaped ends made of boilerplate that has a capacity of treating one to three tonnes of material at a time.[40]

Kier boiling and ''Boiling off'' is the scouring process that involves boiling the materials with the caustic solution in the Kier, which is an enclosed vessel, so that the fabric can boil under pressure.[41][42][43] Open kiers were also used with temperatures below 100 °C (at atmospheric pressure).[5]: 102

Biotechnology

Biotechnology in textiles is the advanced way of processing, textiles, it contributes to numerous treatments of cellulosic materials such as desizing, denim washing, biopolishing, and scouring, etc.[44]

Scouring with enzymes

Enzymes are helpful in bio-singeing, bio-scouring and removing impurities from cotton, which is more environmentally friendly.[45] Biopolishing is an alternative method that is an enzymetic treatment to clean the surface of cellulosic fabrics or yarns. It is also named ''Biosingeing.''[46][47] Pectinase enzymes, breaks down pectin, a polysaccharide found in cellulosic materials such as cotton.[48]

Gallery

.jpg.webp) cotton plant

cotton plant.jpg.webp) Cotton farm

Cotton farm Cotton boll

Cotton boll cotton ready to bale and transported to the mills

cotton ready to bale and transported to the mills

Fabric manufacturing on loom

Fabric manufacturing on loom Fabric manufacturing on knitting machine

Fabric manufacturing on knitting machine The Mather Kier, longitudinal section (Kier, an old method of scouring)

The Mather Kier, longitudinal section (Kier, an old method of scouring)

Silk scouring

Silk is an animal fiber it consists 70–80% fibroin and 20–30% sericin (the gum coating the fibres). It carries impurities like dirt, oils, fats and sericin. The purpose of silk scouring is to remove the coloring matter and the gum that is a sticky substance which envelops the silk yarn. The process is also called ''degumming''. The gum contributes nearly 30 percent of the weight of unscoured silk threads. Silk is called ''boiled off'' when the gum is removed. The process includes the boiling the silk in a soap solution and rinsing it out.[49][14]

Gallery

Silk worms forming cocoon

Silk worms forming cocoon Silk cocoon

Silk cocoon.jpg.webp) Greige silk

Greige silk Silk extraction from cocoon

Silk extraction from cocoon Silk cocoons boiling in water while fibres are extracted

Silk cocoons boiling in water while fibres are extracted Silk hanks ready to process

Silk hanks ready to process.jpg.webp) Dyed silk yarns

Dyed silk yarns

Manmade material Scouring

Oil and dirt are the impurities in Synthetic materials. Certain oils and waxes are applied as lubricants during spinning or fabric manufacturing stages such as knitting or weaving. Mild detergents can remove the impurities effectively.[5]: 116

Effluent of scouring

Effluent is waste water that is thrown away in the water bodies. Industrial wastewater contaminated with scouring residues is heavily contaminated and extremely polluted.[50][5]: 78

See also

References

- Barker, Aldred Farrer; Gardner, Walter Myers; Snow, R.; Cook, William H.; Bradbury, Fred (1910). Textiles. D. Van Nostrand Company. OL 24196864M.

- Matthews, J. Merritt (1921). Bleaching And Related Processes.

- Faculty Of Engineering. p. 18.

- Horrocks, A. Richard; Anand, Subhash C. (2015-12-01). Handbook of Technical Textiles: Technical Textile Processes. Woodhead Publishing. p. 191. ISBN 978-1-78242-481-9.

- Trotman, E. R. (Edward Russell) (1968). Textile scouring and bleaching. Internet Archive. London, Griffin. ISBN 978-0-85264-067-8.

- Collier, Billie J. (2000). Understanding textiles. Internet Archive. Upper Saddle River, NJ : Prentice Hall. ISBN 978-0-13-021951-0.

- Singh, Ram Lakhan; Singh, Rajat Pratap (2018-10-12). Advances in Biological Treatment of Industrial Waste Water and their Recycling for a Sustainable Future. Springer. p. 229. ISBN 978-981-13-1468-1.

- Steven, A. B. (1947). Textile Bleaching. Isaac Pitman and Sons, London. p. 16.

- "Saponification - an overview | ScienceDirect Topics". www.sciencedirect.com. Retrieved 2021-07-28.

- Clark, M. (2011-10-25). Handbook of Textile and Industrial Dyeing: Principles, Processes and Types of Dyes. Elsevier. pp. 65, 66. ISBN 978-0-85709-397-4.

- The Cotton Year Book and Diary. Marsden and Company, Limited. 1919. p. 470.

- "Impurity - an overview | ScienceDirect Topics". www.sciencedirect.com. Retrieved 2021-07-31.

- "Scouring of Cotton with Cellulases, Pectinases and Proteases" (PDF).

- Montazer, Majid; Harifi, Tina (2018-06-20). Nanofinishing of Textile Materials. Woodhead Publishing. p. 41. ISBN 978-0-08-101250-5.

- Smith, William W. (1873). A Complete Etymology of the English Languages: Containing the Anglo-Saxon, French, Dutch ... Roots and the English Words Derived Therefrom ... A.S. Barnes & Company. p. 159.

- Education, United States Office of (1917). Community Leaflet: Lessons in Community and National Life. U.S. Government Printing Office. p. 17.

- Mitchell, Sally (2012-08-06). Victorian Britain (Routledge Revivals): An Encyclopedia. Routledge. p. 866. ISBN 978-1-136-71617-1.

- Heller, Sarah-Grace (2018-11-01). A Cultural History of Dress and Fashion in the Medieval Age. Bloomsbury Publishing. p. 39. ISBN 978-1-350-11410-4.

- Gallant, Thomas W. (2015-01-21). Edinburgh History of the Greeks, 1768 to 1913. Edinburgh University Press. ISBN 978-0-7486-3607-5.

- Purushothama, B. (2019-01-31). Handbook of Value Addition Processes for Fabrics. Woodhead Publishing India PVT. Limited. p. 185. ISBN 978-93-85059-92-6.

- Hampshire Studies: Proceedings of the Hampshire Field Club and Archaeological Society. The Society. 1997. p. 142.

- MacCormick, Donald (1969). Hebridean Folksongs: A Collection of Waulking Songs. Clarendon Press. p. 1.

- Women of The Outer Hebrides - Waulking Song | AI Enhanced – via YouTube

- Hummel, J. J. (John James) (1898). The dyeing of textile fabrics. Harvard University. London [etc.] New York, Cassell and company, limited. p. 92.

- Schools, International Correspondence (1905). Wool, Wool Scouring, Wool Drying, Burr Picking, Carbonizing, Wool Mixing, Wool Oiling: Woolen Carding, Woolen Spinning, Woolen and Worsted Warp Preparation. International Textbook Company. p. 13.

- Company, International Textbook; Schools, International Correspondence (2014). Wool, Wool Scouring, Wool Drying, Burr Picking, Carbonizing, Wool Mixing, Wool Oiling: Woolen Carding, Woolen Spinning, Woolen and Worsted Warp Prepar. Creative Media Partners, LLC. ISBN 978-1-293-67965-4.

- The Colorado Wool Grower and Marketer: Official Organ of Colorado Wool Marketing Association, Colorado State Wool Growers Association, Fort Collins Lamb Feeders Association, Weld County Lamb Feeders Association, and Arkansas Valley Stock Feeders Association. Colorado Wool Marketing Association. 1935. p. 5.

- Garside, Alston Hill (1939). Greasy+wool Wool and the Wool Trade. Frederick A. Stokes Company. p. 24.

- "Lanolin - an overview | ScienceDirect Topics". www.sciencedirect.com. Retrieved 2021-07-28.

- Cyclopedia of textile work : a general reference library on cotton, woollen and worsted yarn manufacture, weaving, designing, chemistry and dyeing, finishing, knitting, and allied subjects. University of Massachusetts Dartmouth Claire T. Carney Library. Chicago : American school of correspondence. 1907. p. 25.

{{cite book}}: CS1 maint: others (link) - Hummel, J. J. (John James) (1898). The dyeing of textile fabrics. Harvard University. London [etc.] New York, Cassell and company, limited. pp. 94, 95.

- Chemical Technology: Wood, paper, textiles, plastics and photographic materials. Barnes & Noble. 1969. p. 353. ISBN 978-0-06-491106-1.

- Survey (U.S.), Geological (1909). Water-supply Paper. U.S. Government Printing Office. p. 7.

- Hummel, John James (1885). The dyeing of textile fabrics. p. 95.

- Bureau (U.S.), Wool (1950). Suggested Research and Development Studies for the Woolen and Worsted Industry. Wool Bureau, Incorporated. p. 5.

- Khadi Gramodyog. Khadi & Village Industries Commission. 1985. p. 44.

- "Wool Scouring | Wool | Wool Bale". Scribd. Retrieved 2021-07-28.

- WO 2013050510, Reutelingsperger, Christiaan Mathias Hubertus Gerard, "A method to wash greasy wool, a method to separate lanolin from the said greasy wool, wool and lanolin obtainable by these methods", published 2013-04-11

- Muthu, Subramanian Senthilkannan (2018-03-08). Sustainable Innovations in Textile Chemistry and Dyes. Springer. p. 45. ISBN 978-981-10-8600-7.

- Knecht, Edmund (1911). . In Chisholm, Hugh (ed.). Encyclopædia Britannica. Vol. 04 (11th ed.). Cambridge University Press. pp. 49–55, see page 50.

Bleaching of Cotton.....Cotton Yarn.—... boiling in alkali is carried out in a "kier," a large, egg-ended, upright cylindrical vessel, constructed of boiler-plate....

- Purushothama, B. (2019-01-31). Handbook of Value Addition Processes for Fabrics. Woodhead Publishing India PVT. Limited. p. 27. ISBN 978-93-85059-92-6.

- Marsh, John Thompson; Wood, Frederick Charles (1945). An Introduction to the Chemistry of Cellulose. Chapman & Hall. p. 26.

- Lacasse, K.; Baumann, Werner (2012-12-06). Textile Chemicals: Environmental Data and Facts. Springer Science & Business Media. p. 95. ISBN 978-3-642-18898-5.

- Aly, A.S; Moustafa, A.B; Hebeish, A. (2004-09-01). "Bio-technological treatment of cellulosic textiles". Journal of Cleaner Production. 12 (7): 697–705. doi:10.1016/S0959-6526(03)00074-X. ISSN 0959-6526.

- Lin, Jianhua (1999). Protease (chymotrypsin, Subtilisin) Scouring of Raw Cotton and Fabric Physical Properties: Effects of Pretreatment, After-reaction Rinse and Further Optimization of Reaction Conditions. University of California, Davis. pp. 23, 24, 28.

- Textile Trends. Eastland Publications. 1999. p. 17.

- Bhatia, S. C. (2017-10-26). Pollution Control in Textile Industry. CRC Press. ISBN 978-1-351-37305-0.

- Sakai, Takuo; Sakamoto, Tatsuji; Hallaert, Johan; Vandamme, Erick J. (1993-01-01). "⌈Pectin, Pectinase, and Protopectinase: Production,⌈ Properties, and Applications". Advances in Applied Microbiology. 39: 213–294. doi:10.1016/S0065-2164(08)70597-5. ISBN 9780120026395. ISSN 0065-2164. PMID 8213306.

- Hummel, John James (1885). The dyeing of textile fabrics. p. 115.

- US EPA, OW (2016-03-17). "Textile Mills Effluent Guidelines". www.epa.gov. Retrieved 2021-07-30.

External links

The dictionary definition of scouring (textiles) at Wiktionary

The dictionary definition of scouring (textiles) at Wiktionary Media related to Scouring (textiles) at Wikimedia Commons

Media related to Scouring (textiles) at Wikimedia Commons