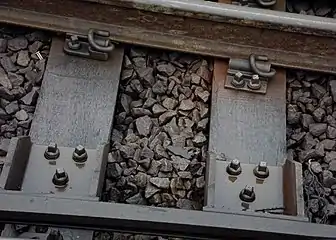

Track ballast

Track ballast is the material which forms the trackbed upon which railroad ties (also known as “sleepers") are laid. It is packed between, below, and around the ties.[1] It is used to bear the compression load of the railroad ties, rails, and rolling stock; to facilitate drainage; and keep down vegetation that can compromise the integrity of the combined track structure.[1] Ballast also physically holds the track in place as the trains roll over it. Not all types of railway tracks use ballast.[2]

A variety of materials have been used as track ballast, including crushed stone, washed gravel, bank run (unwashed) gravel, torpedo gravel (a mixture of coarse sand and small gravel), slag, chats, coal cinders, sand,[3] and burnt clay.[4] The term "ballast" comes from a nautical term for the stones used to stabilize a ship.[1]

Construction

The appropriate thickness of a layer of track ballast depends on the size and spacing of the ties, the amount of traffic on the line, and various other factors.[1] Track ballast should never be laid down less than 150 mm (6 inches) thick,[5] and high-speed railway lines may require ballast up to 0.5 metres (20 inches) thick.[6] An insufficient depth of ballast causes overloading of the underlying soil, and in unfavourable conditions, overloading the soil causes the track to sink, usually unevenly.[7] Ballast less than 300 mm (12 inches) thick can lead to vibrations that damage nearby structures. However, increasing the depth beyond 300 mm (12 inches) confers no extra benefit in reducing vibration.[8]

In turn, track ballast typically rests on a layer of sub-ballast, small crushed stones which provide a solid support for the top ballast and reduces ingress of water from the underlying ground.[1] Sometimes an elastic mat is placed between the sub-ballast and ballast, significantly reducing vibration.[8]

It is essential for ballast to both cover the ties and form a substantial "shoulder".[5] to restraint lateral movement of the track.[9] This shoulder should be at least 150 mm (6 inches) wide, and may be as wide as 450 mm (18 inches),[10]

Stones must be irregular, with sharp edges to ensure they properly interlock with each other and the ties to fully secure them against movement. Speed limits are often reduced for a period of time on sections of track where fresh ballast has been laid in order to allow it to properly settle.[11]

Ballast can only be cleaned so often before is damaged beyond re-use. Ballast that is completely fouled can not be corrected by shoulder cleaning.[12] One method of "replacing" ballast is to simply dump fresh ballast on the track, jack the whole track on top of it, and then tamp it down.[13] Alternatively, the ballast underneath the track can be removed with an undercutter, which does not require removing or lifting the track.[12]

The dump and jack method cannot be used through tunnels, under bridges, or where there are platforms. Where the track is laid over a swamp the ballast is likely to sink continuously, and needs to be "topped up" to maintain its line and level. After 150 years of topping up at Hexham, Australia, there appears to be 10 m (33 ft) of sunken ballast under the tracks.[14] Chat Moss in the United Kingdom is similar.

Regular inspection of the ballast shoulder is important.[5] The shoulder acquires some amount of stability over time, being compacted by traffic, but maintenance tasks such as replacing ties, tamping, and ballast cleaning can upset that stability. After performing those tasks, it is necessary either for trains to run at reduced speed on the repaired sections, or to employ machinery to compact the shoulder again.[15][16]

If the trackbed becomes uneven, it is necessary to pack ballast underneath sunken ties to level the track again, which is usually done by a ballast tamping machine. A more recent, and probably better,[6] technique is to lift the rails and ties, and to force stones, smaller than the track ballast particles and all of the same size, into the gap. That has the advantage of not disturbing the well-compacted ballast on the trackbed, which tamping is likely to do.[17] The technique is called pneumatic ballast injection (PBI), or, less formally, "stoneblowing".[18] However, it is not as effective as fresh ballast, because the smaller stones tend to move down between the larger pieces of ballast and degrade its bonds.[19]

Quantities

The quantity of ballast used tends to vary with gauge, with the wider gauges tending to have wider formations, although one report states that for a given load and speed, narrowing the gauge only slightly reduces the quantity of earthwork and ballast needed. The depth of ballast also tends to vary with the density of rail traffic, as faster and heavier traffic requires greater stability. The quantity of ballast also tends to increase over the years as more and more ballast is piled onto an existing roadbed. Some figures from an 1897 report listing requirements for light railways (usually narrower than standard gauge) are:

Footnotes

- Solomon (2001), p. 18.

- Tubular Modular Track

- Kellogg, H. W. (1946). "Selection and Maintenance of Ballast" (PDF). American Railway Engineering and Maintenance-of-Way Association. Retrieved 27 March 2021.

- Beyer, S. W.; Williams, I. A. (1904). The Geology of Clays. pp. 534–537.

- Bonnett (2005), p. 60.

- Bell 2004, p. 396.

- Hay 1982, p. 399.

- Bachmann 1997, p. 121.

- Hay (1982), p. 407.

- 150 mm (6 inches) is with 300 mm (12 inches) recommended for use in heavy traffic, or with continuous welded rail or concrete ties. Most railways use between 300 and 400 mm (12 and 16 inches). A 450 mm (18 in) shoulder significantly increases lateral stability and reduces required maintenance, though little or no resistance to buckling is gained above this size. See Hay (1982), pp. 407-408; Kutz (2004), Section 24.4.2

- Bibel, George (2012). Train Wreck: The Forensics of Rail Disasters. Baltimore, MD: Johns Hopkins University Press. pp. 287–88. ISBN 9781421405902.

- Solomon 2001, p. 43.

- Solomon (2001), p. 41.

- Nasir, Enamul. "Railway Materials Case Study". Retrieved 4 August 2016.

- Hay 1982, p. 408.

- Kutz 2004, Section 24.4.2.

- Anderson & Key (1999).

- Ellis (2006), p. 265, Pneumatic Ballast Injection

- IFSC #37, ch. 9.

- "LIGHT RAILWAYS". The Brisbane Courier. National Library of Australia. 29 September 1897. p. 5. Retrieved 21 May 2011.

References

- Anderson, W. F.; Key, A. J. (1999). "Two layer ballast beds as railway track foundations". Twelfth European Conference on Soil Mechanics and Geotechnical Engineering (Proceedings). AA Balkema. ISBN 90-5809-047-7.

- Bachmann, Hugo; et al. (1997). Vibration Problems in Structures: Practical Guidelines. Birkhäuser. ISBN 3-7643-5148-9.

- Bell, F.G. (2004). Engineering Geology and Construction. Spon Press. ISBN 0-415-25939-8.

- Bonnett, Clifford F. (2005). Practical Railway Engineering (2nd ed.). London, UK: Imperial College Press. ISBN 978-1-86094-515-1. OCLC 443641662.

- Ellis, Iain (2006). Ellis' British Railway Engineering Encyclopaedia. Lulu.com. ISBN 1-84728-643-7.

- Hay, William Walter (1982). Railroad Engineering. John Wiley and Sons. ISBN 0-471-36400-2.

- Indraratna, Buddhima (2011). Advanced rail geotechnology--ballasted track. Leiden, The Netherlands: CRC Press/Balkema. ISBN 978-0-203-81577-9.

- Institution of Civil Engineers (1988). Urban Railways and the Civil Engineer. Thomas Telford. ISBN 0-7277-1337-X.

- International Federation for Structural Concrete (fédération internationale du béton) bulletin #37.

- Kutz, Myer (2004). Handbook of Transportation Engineering. McGraw-Hill. ISBN 0-07-139122-3.

- Selig, Ernest Theodore; Waters, John M. (1994). Track Geotechnology and Substructure Management. Thomas Telford. ISBN 0-7277-2013-9.

- Solomon, Brian (2001). Railway Maintenance Equipment: The Men and Machines that Keep the Railroads Running. MBI Publishing Company. ISBN 0-7603-0975-2.

Further reading

- New South Wales: Ballast 1850-1987 Longworth, Jim Australian Railway History, December, 2004 pp443–462