BACKGROUND

Demands imposed by the U.S. participation in World War II turned out to be the most effective measure to battle the long-lasting consequences of the Great Depression. The Roosevelt administration followed its New Deal approach and aimed to maintain significant control over the economy although many in the private industry resisted the idea. Government programs continued to recruit workers but this time the demand was fueled not by the economic crisis but by massive war demands. Production sped up dramatically, closed factories reopened and new ones were established creating millions of jobs in both private and public sectors, and many industries adjusted to the nearly insatiable needs of the military. Two-thirds of the American economy had been integrated into the war effort by the end of 1943.

Following the New Deal practice, the Roosevelt Administration established a number of new government agencies or expanded the role of those launched under the New Deal in order to convert the peacetime economy to the requirements imposed by the war effort. The Reconstruction Finance Corporation (RFC), originally established to provide loans to businesses, was now in control of eight wartime subsidiaries responsible for the management of critical natural resources and the production of synthetic alternatives at the time of constantly scarce supplies. The Office of Production Management (OPM) and the Supply Priorities and Allocations Board were both in charge of how natural resources were used for the war effort. The Office of Price Administration (OPA) was established within the Office for Emergency Management on August 28, 1941 to control prices (and thus inflation) and rents after the outbreak of World War II.

WAR PRODUCTION BOARD

The most powerful of all war-time organizations whose task was to control the economy was the War Production Board (WPB), established by Roosevelt on January 16, 1942 by executive order. Its purpose was to regulate the production of materials during World War II in the United States. The WPB converted and expanded peacetime industries to meet war needs, allocated scarce materials vital to war production, established priorities in the distribution of materials and services, and prohibited nonessential production. It rationed such commodities as gasoline, heating oil, metals, rubber, paper, and plastics.

The WPB and the nation's factories effected a great turnaround. Military aircraft production, which totaled 6,000 in 1940, jumped to 85,000 in 1943. Factories that made silk ribbons now produced parachutes, automobile factories built tanks, typewriter companies converted to machine guns, undergarment manufacturers sewed mosquito netting, and a roller coaster manufacturer converted to the production of bomber repair platforms. The WPB ensured that each factory received the materials it needed to produce the most war goods in the shortest time. In 1942-45, WPB supervised the production of $183 billion worth of weapons and supplies, about 40% of the world output of munitions. Britain, the USSR and other allies produced an addition 30%, while the Axis produced only 30%. One fourth of the US output was warplanes; one fourth was warships. Meanwhile, the civilian standard of living was about level.

The War Production Board was dissolved shortly after the defeat of Japan in 1945, and was replaced by the Civilian Production Administration in late 1945. Commercial institutions that had bought billions of dollars of bonds and other treasury paper during the war years, were estimated to be holding more than $24 billion at the war's end.

RATIONING

The greatest challenge of such massive war-related production was the permanent scarcity of resources. In response to it, the U.S. government, similarly to other states engaged in the war, introduced severe rationing measures.

Tires were the first item to be rationed by the OPA, which ordered the temporary end of sales on 11 December 1941 while it created 7,500 unpaid, volunteer three-person tire ration boards around the country. There was a shortage of rubber for tires since the Japanese quickly conquered the rubber-producing regions of Southeast Asia. Although synthetic rubber had been invented before the war, it had been unable to compete with natural rubber commercially, so the US did not have enough manufacturing capacity at the start of the war to make synthetic rubber. Throughout the war, rationing of gasoline was motivated by a desire to conserve rubber as much as by a desire to conserve gasoline. A national speed limit of 35 miles per hour was imposed to save fuel and rubber for tires.

The WPB ordered the temporary end of all civilian automobile sales on 1 January 1942, leaving dealers with one half million unsold cars. Automobile factories stopped manufacturing civilian models by early February 1942 and converted to producing tanks, aircraft, weapons, and other military products, with the United States government as the only customer. As of 1 March 1942, dog food could no longer be sold in tin cans, and manufacturers switched to dehydrated versions. As of 1 April 1942, anyone wishing to purchase a new toothpaste tube, then made from metal, had to turn in an empty one. By June 1942 companies also stopped manufacturing metal office furniture, radios, phonographs, refrigerators, vacuum cleaners, washing machines, and sewing machines for civilians.

Sugar was the first consumer commodity rationed, with all sales ended on 27 April 1942. Coffee was rationed nationally on 29 November 1942. By the end of 1942, ration coupons were used for nine other items. Typewriters, gasoline, bicycles, footwear, silk, nylon, fuel oil, stoves, meat, lard, shortening and food oils, cheese, butter, margarine, processed foods (canned, bottled, and frozen), dried fruits, canned milk, firewood and coal, jams, jellies, and fruit butter were rationed by November 1943. Scarce medicines such as penicillin were rationed by triage officers in the US military during World War II.

LABOR

The unemployment problem ended with the mobilization for war, hitting an all-time low of 700,000 in fall 1944. There was a growing labor shortage in war centers, with sound trucks going street by street begging for people to apply for war jobs. Greater wartime production created millions of new jobs, while the draft reduced the number of young men available for civilian jobs. So great was the demand for labor that millions of retired people, housewives, and students entered the labor force, lured by patriotism and wages. The shortage of grocery clerks caused retailers to convert from service at the counter to self-service. Before the war most groceries, dry cleaners, drugstores, and department stores offered home delivery service. The labor shortage and gasoline and tire rationing caused most retailers to stop delivery. They found that requiring customers to buy their products in person increased sales.

Labor shortages were felt in agriculture, even though most farmers were given an exemption and few were drafted. Large numbers volunteered or moved to cities for factory jobs. At the same time many agricultural commodities were in greater demand by the military and for the civilian populations of Allies. Production was encouraged and prices and markets were under tight federal control. Civilians were encouraged to create "victory gardens", farms that were often started in backyards and lots. Children were encouraged to help with these farms.

Because of the unprecedented labor demands, groups that were historically excluded from the labor market, particularly African Americans and women, received access to jobs. However, even the existing circumstances did not end discrimination, especially against the workers of color.

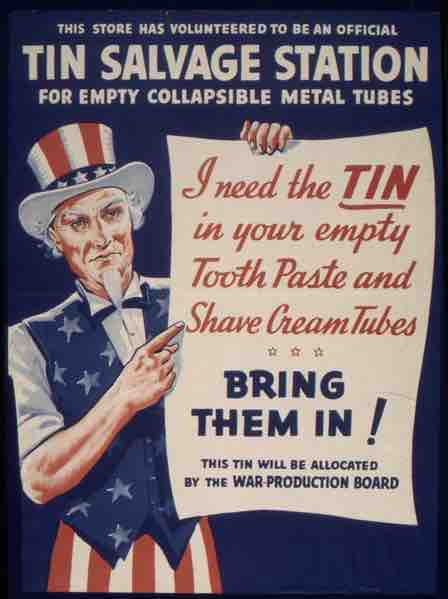

War Poster for Tin Salvage, Office for Emergency Management, 1941-1945.

Tin salvage station for empty collapsible metal tubes.