Mining Feature: Intelligent Proximity Detection to Improve Miner Safety

Monday, November 28, 2011

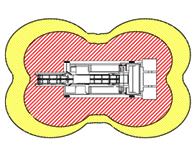

Current magnetic proximity systems create zones around the equipment defining a broad area within which the miner is located.

MSHA recently announced a proposed rule requiring that continuous mining machines be equipped with proximity detection systems. NIOSH has been working on this problem for over ten years and believes that an Intelligent Proximity Detection (IPD) system may be the answer to keeping miners safe around underground equipment. Continuous mining machines, the initial target of the rule, present one of the biggest challenges to safety because of the number of workers close to the machine and the variety of ways the machine can move, pivot and tram.

How Big is the Problem?

- Since 1984 there were 33 fatalities where a miner was struck or pinned by a continuous mining machine

- According to MSHA, a proximity detection system disabling the machine could have helped avoid 80% of those 33 fatalities

- MSHA estimates that proximity detection technology can prevent as many as 20% of all mining-related deaths

The Office of Mine Safety and Health Research (OMSHR) has developed specific research goals for preventing injuries involving powered machinery, and proximity detection is currently the primary research focus in this area. NIOSH has acted as an impartial third party to evaluate commercially available systems and is developing a prototype intelligent system that provides enhanced protection by continuously monitoring miners’ positions in relation to the machine and established safety zones.

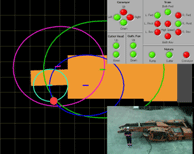

The NIOSH Intelligent Proximity Detection System uses multiple generators to determine the position of the worker relative to the equipment, only disabling those functions that would threaten worker safety.

NIOSH first developed electromagnetic proximity detection technology over ten years ago as the Hazardous Area Signaling and Ranging Device (HASARD). This system uses an electromagnetic field generator to create a magnetic field measurable by a wearable Personal Alarm Device (PAD), which gives a rough indication of the distance between the generator and the PAD. Several manufacturers adopted the concepts developed with HASARD and further refined the technology, and a number of such systems are now commercially available.

While these systems undoubtedly improve the safety of miners, they still only define a broad area around the machine within which the miner is located. A greater level of protection is possible with the implementation of a more intelligent system. The NIOSH IPD system will provide this enhanced protection by continuously tracking the positions of all miners near the machine and making situational decisions based on these positions. Instead of completely disabling the mining machine, the IPD system prevents only potentially hazardous machine motion. In addition to providing more intelligent protection, the IPD system enhances operator acceptance by limiting the frustration associated with frequent false alarms and full stops of all machine operations.

Here are some links to MSHA related to Proximity Detection:

- MSHA Proposed Rule and Notice of Public Hearings

- Proximity Detection Systems for Continuous Mining Machines in Underground Coal Mines

- MSHA Proximity Detection / Collision Warning Single Source Page

See Also

- Effect of Operator Position on the Incidence of Continuous Mining Machine/Worker Collisions

- Engineering Considerations and Selection Criteria for Proximity Warning Systems for Mining Operations

- Evaluation of an advanced proximity detection system for continuous mining machines

- Innovative Safety Interventions: Feasibility of Using Intelligent Video for Machinery Applications

- A Performance Evaluation of Two Overhead Power Line Proximity Warning Devices

- Proximity Detection

- Proximity Detection With Selective Machine Shutdown

- Proximity Detection Zones: Designs to Prevent Fatalities Around Continuous Mining Machines

- Recommendations for Evaluating & Implementing Proximity Warning Systems on Surface Mining Equipment

- Test Results of Collision Warning Systems for Surface Mining Dump Trucks

- Page last reviewed: 10/26/2016

- Page last updated: 9/28/2012

- Content source: National Institute for Occupational Safety and Health, Mining Program

ShareCompartir

ShareCompartir