Mining Contract: Snake Robot for Mine Rescue

| Contract # | 200-2009-30721 |

|---|---|

| Start Date | 8/10/2009 |

| End Date | 6/30/2012 |

| Research Concept | In mine rescue operations the ability to rapidly locate trapped miners and assess their situation (vital signs, air quality, etc.) is of the essence. Locating personnel trapped in the mine and delivering initial aid requires that reconnaissance equipment be lowered to the mine via a narrow vertical borehole, up to 2,000 ft long. Currently available robots either cannot fit through such a narrow (4 to 5 in dia) access port, or cannot deliver the mobility and sensing capabilities that is required to assess the situation and determine the location and vital status of trapped miners. |

| Topic Area |

Contract Status & Impact

This contract is complete. To receive a copy of the final report, send a request to mining@cdc.gov.

After a large-scale mine fire or explosion, a borehole is often drilled into the mine and a camera is lowered into the borehole for the purpose of a limited visual inspection. Following this, a tubing string is installed down the borehole to determine the atmospheric conditions at that specific location in the mine. The ability to provide visual inspection and measurement of atmospheric conditions beyond the borehole location itself is critical to improve the quality data needed and used by rescue operations for decisionmaking.

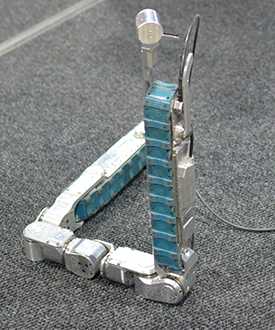

In August 2009, a contract was awarded to Raytheon Sarcos to leverage its ongoing development of the new generation tandem track snake robot, by modifying this system in a way to make it suitable for operations in underground mines. Raytheon Sarcos had successfully demonstrated the functionality and utility of the snake robot technology under a Defense Advanced Research Projects Agency (DARPA) funded contract. The company also began development of the next generation of a new class of snake-inspired robots that had unprecedented multi-dimensional mobility and maneuverability in a broad range of terrains and environments.

Under this contract, the design constraints for the snake robot included: ability to move at 1 to 2 miles per hour in the mine opening; maintain mobility through a debris field, including mud and standing water; operate tethered with cabling of sufficient strength to be lowered vertically 2,000 ft through a borehole, sized to fit inside a 4-in-diameter borehole; ability to detect oxygen, methane, carbon monoxide, and temperature; enable two-way voice communication; provide 200-ft minimum lateral illumination with color and infrared video; receive power through onboard batteries and the tether cable.

In fiscal year 2013, the construction of the snake robot was completed along with lab testing. Robot performance was also evaluated in an OMSHR test mine. The in-mine evaluations involved three robot operator scenarios. In the first evaluation, the robot operator trailed the robot in the mine to permit the operator to become familiar with the mine conditions; in the second evaluation, the robot operator was located in the mine, but out of sight of the robot; in the final evaluation, the robot operator was located on the surface and the robot was lowered into the mine via a borehole. In each case, the robot successfully navigated obstacle courses designed to simulate post-event debris.

See Also

- Effects of Far-Field Shearing Deformation on Fracturing Around an Underground Opening

- Performance Comparison of Rescue Breathing Apparatus

- Preventing Injuries Caused by Unrecognized Stone Mine Roof Beam Failures With a Pro-Active Roof Control Plan

- Refuge Alternatives in Underground Coal Mines

- SPONCOM - A Computer Program for the Prediction of the Spontaneous Combustion Potential of an Underground Coal Mine

- SponCom - Spontaneous Combustion Assessment Software - 2.0

- Technology News 545 - NIOSH Updates Spontaneous Combustion Assessment Software

- Technology Upgrade of the Sarcos Snake Robot

- Underground Mine Communications, Control and Monitoring

- Water and Slurry Bulkheads in Underground Coal Mines: Design, Monitoring, and Safety Concerns

- Page last reviewed: 1/11/2017

- Page last updated: 7/18/2014

- Content source: National Institute for Occupational Safety and Health, Mining Program

ShareCompartir

ShareCompartir