Ceramic Filtration

Ceramic Filtration [PDF – 2 pages]

Locally manufactured ceramic filters have traditionally been used throughout the world to treat household water. Currently, the most widely implemented ceramic filter is the Potters for Peace design. The filter is flowerpot shaped, holds about 8-10 liters of water, and sits inside a plastic or ceramic receptacle. To use the ceramic filters, families fill the top receptacle or the ceramic filter itself with water, which flows through the ceramic filter or filters into a storage receptacle. The treated water is then accessed via a spigot embedded within the water storage receptacle. The filters are produced locally at ceramics facilities, and then impregnated with colloidal silver to ensure complete removal of bacteria in treated water and to prevent growth of bacteria within the filter itself. Numerous other locally-made and commercial ceramic filters are widely available in developed and developing countries.

Lab Effectiveness, Field Effectiveness, and Health Impact

The effectiveness of ceramic filters at removing bacteria, viruses, and protozoa depends on the production quality of the ceramic filter. Most ceramic filters are effective at removing bacteria and the larger protozoans, but not at removing the viruses. Studies have shown adequate removal of bacterial pathogens in water filtered through high quality locally-produced or imported ceramic filters in developing countries. A 60-70% reduction in diarrheal disease incidence has been documented in users of these filters. Studies have also shown significant bacterial contamination when poor-quality locally produced filters are used, or when the receptacle is contaminated at the household level. Because there is no chlorine residual protection, it is important that users be trained to properly care for and maintain the ceramic filter and receptacle.

Benefits, Drawbacks, and Appropriateness

The Potters for Peace filter locally produced in Nicaragua (D. Lantagne, CDC)

The benefits of ceramic filtration are:

- Proven reduction of bacteria and protozoa in water

- Simplicity of use and acceptability

- Proven reduction of diarrheal disease incidence for users

- Long life if the filter remains unbroken

- A low one-time cost

The drawbacks of ceramic filtration are:

- Not as effective against viruses

- No chlorine residual protection – can lead to recontamination

- Variable quality control for locally produced filters

- Filters can break over time – need for spare parts

- A low flow rate of 1-3 liters per hour for non-turbid waters

- Filters and receptacles must be cleaned regularly, especially after filtering turbid water

Ceramic filtration is most appropriate in areas where there is capacity for quality ceramics filter production, a distribution network for replacement of broken parts, and user training on how to correctly maintain and use the filter.

Implementation Examples

Placing the ceramic pot in a receptacle (R. Rivera, PFP)

Ceramic filtration programs have been implemented in over 20 countries.

Potters for Peace (PFP) is a United States and Nicaragua based non-governmental organization (NGO) that promotes the flower-pot ceramic filter design by providing technical assistance to organizations interested in establishing a filter factory. PFP has assisted in establishing filter-making factories in many countries. Once the filter factory is established, the factory markets the filters to NGOs who then incorporate the filter into their own water and sanitation programming.

The first PFP filter factory, in Managua, Nicaragua, was constructed using private donations. From 1999-2005, the filter factory was a self-financed recognized micro-enterprise in Nicaragua. NGOs paid $10 per filter, and transported the filters themselves to project locations. Despite the fact that 23,000 filters were made and sold in Nicaragua from 1999-2004, the factory was not financially sustainable and was sold in 2005 to a private investor who increased the price of each filter.

One of the largest ceramic filtration programs is in Cambodia, where two NGOs both worked with PFP to establish filter factories. Resources Development International distributes the filters through unsubsidized direct sales, distribution through local vendors, and community-based subsidized programs. International Development Enterprises distributes the filters nationally through vendors. Both NGOs sell filters to government agencies and other NGOs. The project has successfully distributed over 200,000 filters and has been extensively studied.

Economics and Scalability

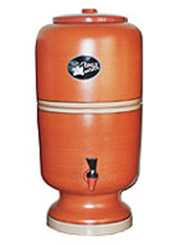

Commercially available ceramic filter system. (Stefani Australasia)

Locally manufactured ceramic PFP-design filters range in cost from $7.50-$30. Distribution, education, and community motivation can add significantly to program costs. Ceramic filter programs can achieve full cost recovery (charging the user the full cost of product, marketing, distribution, and education), partial cost recovery (charging the user only for the filter, and subsidizing program costs with donor funds), or be fully subsidized such as in emergency situations. If a family filters 20 liters of water per day (running the filter continuously) and the filter lasts 3 years then the cost per liter treated (including cost of filter only) is 0.034-0.14 US cents.

Commercially available ceramic filter systems range in cost from tens to hundreds of US dollars, depending on where they are manufactured and purchased, and the quality of the ceramic filters. The economics and the sustainability of commercial product-based projects depend on donor funding and subsidy, as well as follow-up to ensure replacement parts are accessible to the population using the filters.

Additional Resources

For more information about using ceramic filtration for household water treatment, visit:

- Page last reviewed: March 21, 2012

- Page last updated: March 21, 2012

- Content Source:

ShareCompartir

ShareCompartir