Sanitary sewer

A sanitary sewer is an underground pipe or tunnel system for transporting sewage from houses and commercial buildings (but not stormwater) to a sewage treatment plant or disposal. Sanitary sewers are a type of gravity sewer and are part of an overall system called a "sewage system" or sewerage. Sanitary sewers serving industrial areas may also carry industrial wastewater. In municipalities served by sanitary sewers, separate storm drains may convey surface runoff directly to surface waters. An advantage of sanitary sewer systems is that they avoid combined sewer overflows. Sanitary sewers are typically much smaller in diameter than combined sewers which also transport urban runoff. Backups of raw sewage can occur if excessive stormwater inflow or groundwater infiltration occurs due to leaking joints, defective pipes etc. in aging infrastructure.

Purpose

Sewage treatment is less effective when sanitary waste is diluted with stormwater, and combined sewer overflows occur when runoff from heavy rainfall or snowmelt exceeds the hydraulic capacity of sewage treatment plants.[1] To overcome these disadvantages, some cities built separate sanitary sewers to collect only municipal wastewater and exclude stormwater runoff, which is collected in separate storm drains. The decision to build a combined sewer system or two separate systems is mainly based on the need for sewage treatment and the cost of providing treatment during heavy rain events. Many cities with combined sewer systems built their systems prior to installing sewage treatment plants, and have not subsequently replaced those sewer systems.[2]

Types

Conventional gravity sewers

In the developed world, sewers are pipes from buildings to one or more levels of larger underground trunk mains, which transport the sewage to sewage treatment facilities. Vertical pipes, usually made of precast concrete, called manholes, connect the mains to the surface. Depending upon site application and use, these vertical pipes can be cylindrical, eccentric, or concentric. The manholes are used for access to the sewer pipes for inspection and maintenance, and as a means to vent sewer gases. They also facilitate vertical and horizontal angles in otherwise straight pipelines.[4]

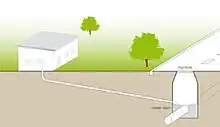

Pipes conveying sewage from an individual building to a common gravity sewer line are called laterals. Branch sewers typically run under streets receiving laterals from buildings along that street and discharge by gravity into trunk sewers at manholes. Larger cities may have sewers called interceptors, receiving flow from multiple trunk sewers.[5][6]

Design and sizing of sanitary sewers considers the population to be served over the anticipated life of the sewer, per capita wastewater production, and flow peaking from timing of daily routines. Minimum sewer diameters are often specified to prevent blockage by solid materials flushed down toilets; and gradients may be selected to maintain flow velocities generating sufficient turbulence to minimize solids deposition within the sewer. Commercial and industrial wastewater flows are also considered, but diversion of surface runoff to storm drains eliminates wet weather flow peaks of inefficient combined sewers.[7]

Force mains

A force main or rising main[8] is a pumped sewer that may be necessary where gravity sewers serve areas at lower elevations than the sewage treatment plant, or distant areas at similar elevations. A lift station is a sewer sump that lifts accumulated sewage to a higher elevation. They may also be used to prime an inverted siphon used to cross underneath rivers or other obstructions. The pump may discharge to another gravity sewer or directly to a treatment plant.[6] Force mains are typically constructed of welded steel or HDPE jointed to resist pressures within the pipe. Force mains are substantially different from pressure sewers which serve individual properties or groups of properties and provide a means of injecting sewage into a local gravity main.

Effluent sewer

Effluent sewer systems, also called septic tank effluent drainage (STED) or solids-free sewer (SFS) systems, have septic tanks that collect sewage from residences and businesses, and the effluent that comes out of the tank is sent to either a centralized sewage treatment plant or a distributed treatment system for further treatment. Most of the solids are removed by the septic tanks, so the treatment plant can be much smaller than a typical plant. In addition, because of the vast reduction in solid waste, a pumping system, rather than a gravity system, can be used to move the wastewater. The pipes have small diameters, typically 1.5 to 4 inches (4 to 10 cm). Because the waste stream is pressurized, they can be laid just below the ground surface along the land's contour.

Pressure sewer

Where it is impossible or impractical to discharge sewage from a property into a gravity sanitary sewer, a pressure sewer may provide an alternative means of connection. A macerator pump in a pumping well close to the property ejects sewage through a small diameter high pressure pipe into the nearest gravity sewer.[9]

Simplified sewer

Simplified sanitary sewers consist of small-diameter pipes, typically around 100 millimetres (4 in), often laid at fairly flat gradients (1 in 200). Although the investment cost for simplified sanitary sewers can be about half the cost of conventional sewers, the requirements for operation and maintenance are usually higher. Simplified sewers are most common in Brazil and are also used in a number of other developing countries.

Vacuum sewer

In low-lying communities, wastewater is often conveyed by vacuum sewer. Pipelines range in size from pipes of 10 centimetres (3.9 in) in diameter to concrete-lined tunnels of up to 9 metres (30 ft) in diameter. A low pressure system uses a small grinder pump located at each point of connection, typically a house or business. Vacuum sewer systems use differential atmospheric pressure to move the liquid to a central vacuum station.[10]

Maintenance

Sanitary sewer overflow can occur due to blocked or broken sewer lines, infiltration of excessive stormwater or malfunction of pumps. In these cases untreated sewage is discharged from a sanitary sewer into the environment prior to reaching sewage treatment facilities. To avoid this, maintenance is required.

The maintenance requirements vary with the type of sanitary sewer. In general, all sewers deteriorate with age, but infiltration and inflow are problems unique to sanitary sewers, since both combined sewers and storm drains are sized to carry these contributions. Holding infiltration to acceptable levels requires a higher standard of maintenance than necessary for structural integrity considerations of combined sewers.[11] A comprehensive construction inspection program is required to prevent inappropriate connection of cellar, yard, and roof drains to sanitary sewers.[12] The probability of inappropriate connections is higher where combined sewers and sanitary sewers are found in close proximity, because construction personnel may not recognize the difference. Many older cities still use combined sewers while adjacent suburbs were built with separate sanitary sewers.

For decades, when sanitary sewer pipes cracked or experienced other damage, the only option was an expensive excavation, removal and replacement of the damaged pipe, typically requiring street repavement afterwards. In the mid-1950s a unit was invented where two units at each end with a special cement mixture in between was pulled from one manhole cover to the next, coating the pipe with the cement under high pressure, which then cured rapidly, sealing all cracks and breaks in the pipe.[13] Today, a similar method using epoxy resin is used by some municipalities to re-line aging or damaged pipes, effectively creating a "pipe in a pipe". These methods may be unsuitable for locations where the full diameter of the original pipe is required to carry expected flows, and may be an unwise investment if greater wastewater flows may be anticipated from population growth, increased water use, or new service connections within the expected service life of the repair.

Another popular method for replacing aged or damaged lines is called pipe bursting, where a new pipe, typically PVC or ABS plastic, is drawn through the old pipe behind an "expander head" that breaks apart the old pipe as the new one is drawn through behind it.

These methods are most suitable for trunk sewers, since repair of lines with lateral connections is complicated by making provisions to receive lateral flows without accepting undesirable infiltration from inadequately sealed junctions.

Ventilation

Sometimes a sewer has a tall vent pipe to release foul gases well up away from people. Common names are, stink pipe, stink pole, stench pipe and sewer ventilation pipe.[14]

History

Sanitary sewers evolved from combined sewers built where water was plentiful. Animal feces accumulated on city streets while animal-powered transport moved people and goods. Accumulations of animal feces encouraged dumping chamber pots into streets where night soil collection was impractical.[15] Combined sewers were built to use surface runoff to flush waste off streets and move it underground to places distant from populated areas. Sewage treatment became necessary as population expanded, but increased volumes and pumping capacity required for treatment of diluted waste from combined sewers is more expensive than treating undiluted sewage.[16]

Communities that have urbanized in the mid-20th century or later generally have built separate systems for sewage (sanitary sewers) and stormwater, because precipitation causes widely varying flows, reducing sewage treatment plant efficiency.[17]

In the UK, the term "foul sewer" was also in use for a sanitary sewer.

See also

- Blackwater (waste)

- Fatberg (sewer obstruction)

- Greywater

- Sewer mining

- Water pollution

References

- ↑ Report to Congress: Impacts and Control of CSOs and SSOs (Report). Washington, D.C.: U.S. Environmental Protection Agency (EPA). August 2004. p. ES-2. EPA-833-R-04-001.

- ↑ Metcalf & Eddy, Inc. (1972). Wastewater Engineering: collection, treatment, disposal. New York: McGraw–Hill. p. 119. ISBN 9780070416765.

- ↑ Tilley, E., Ulrich, L., Lüthi, C., Reymond, Ph., Zurbrügg, C. (2014) Compendium of Sanitation Systems and Technologies (2nd Revised Edition). Swiss Federal Institute of Aquatic Science and Technology (Eawag), Duebendorf, Switzerland. ISBN 978-3-906484-57-0.

- ↑ "Acu-Sewer Pressure Pipe for Sewer Mains". Acu-Tech Piping Systems. Retrieved 2018-10-03.

- ↑ Lee, C.C., ed. (2005). Environmental Engineering Dictionary (4th ed.). Lanham, MD: Government Institutes. p. 423. ISBN 9780865878488.

- 1 2 Design and Construction of Sanitary and Storm Sewers. New York: American Society of Civil Engineers and Water Pollution Control Federation. 1969. pp. 2, 288.

- ↑ Tyler, Richard G. (1959). "Section 9". Civil Engineering Handbook (4th ed.). New York: McGraw-Hill. pp. 1–24.

- ↑ "Design and Construction Guidance for foul and surface water sewers offered for adoption under the Code for adoption agreements for water and sewerage companies operating wholly or mainly in England ("the Code")" (PDF). Water UK. March 2020. p. 6. Retrieved 18 January 2022.

- ↑ Stauffer, Beat; Spuhler, Dorothee. "Pressurised Sewers". Sustainable Sanitation and Water Management Toolbox. Retrieved 18 January 2022.

- ↑ Wastewater Treatment/Disposal for Small Communities: Manual (Report). EPA. 1992. pp. 84–88. EPA 625/R-95/005.

- ↑ Hammer, Mark J. Water and Waste-Water Technology (1975) John Wiley & Sons ISBN 0-471-34726-4 p.442

- ↑ Steel, E.W.; McGhee, Terence J. (1979). Water Supply and Sewerage (5th ed.). New York: McGraw-Hill. p. 22. ISBN 0-07-060929-2.

- ↑ "Sewer Sealing Machine Patches Cracks Underground." Popular Mechanics, April 1956, p. 86.

- ↑ https://www.thenorthernecho.co.uk/history/3211527.just-tip-stink-pole/

- ↑ Bellis, Mary (2018-03-31). "The History of Plumbing". Archived from the original on 2017-10-14. Retrieved 2018-05-14. Alt URL

- ↑ Steel, E.W.; McGhee, Terence J. (1979). Water Supply and Sewerage (5th ed.). New York: McGraw-Hill. p. 318. ISBN 0-07-060929-2.

- ↑ Burrian, Steven J., et al. (1999). "The Historical Development of Wet-Weather Flow Management." US Environmental Protection Agency (EPA). National Risk Management Research Laboratory, Cincinnati, OH. Document No. EPA/600/JA-99/275.

| Wikimedia Commons has media related to Sanitary sewer. |