wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 11 people, some anonymous, worked to edit and improve it over time.

This article has been viewed 114,034 times.

Learn more...

When you emboss metal, you participate in an art form that has existed for centuries. Metal embossing is used to impart a design upon metal sheets. The metal is pushed with an embossing tool or stylus in order to create a raised effect on the opposite side. By placing the metal sheet on a rubber or foam pad, the positive impression has a smooth surface that will shine or can take pigment. Embossed metal sheets can be used to decorate items like tins, lanterns, windows or doors. Smaller pieces can also be used to decorate greeting cards or scrapbooks. Embossing metal does not require many tools. The steps below will present you with a tried and true method of metal embossing.

Steps

-

1Transfer your design to the metal sheet.[1]

- Print out or draw your design on a piece of paper. It can be helpful to use a piece of paper that is the same size as your metal sheet.

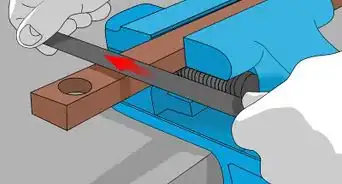

- Tape the edges of your metal sheet to the piece of paper with your template design. Place a piece of tape on all sides to ensure the page does not slip. This will ensure that your lines are true to the design.

- Using the stylus, trace over the lines of your template design. Use as little pressure as possible, so that you are not committed to a high relief. This cannot easily be undone, so follow the lines as close to exact as possible.

-

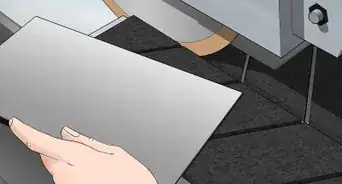

2Remove the paper and tape from the metal sheet.Advertisement

-

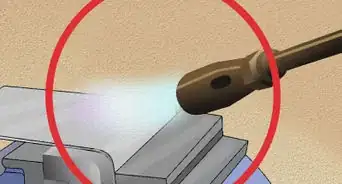

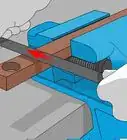

3Deepen the lines on the metal sheet using the stylus to your preference. The harder you press, the deeper the line.[2]

-

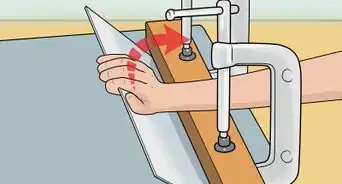

4Fill in the lines with the embossing tool. Again, more pressure yields more relief (negative from the side you're working, positive from opposite side).[3]

Community Q&A

-

QuestionWhat is the best thickness for a beginner embossing copper?

Community AnswerAt craft stores such as Hobby Lobby you can buy a roll of copper at 36 gauge (the higher the gauge, the thinner the sheet). I have used this to good effect. Pushing from the back is called "repousse" and pushing from the front is called "chasing." If you look up chasing and repousse tools on Google, you'll find places that sell all sorts of tools for this type of art. I'd recommend Mettleworks.com since they have sets as well as individual tools. Do some reading online before you decide which tools to buy.

Community AnswerAt craft stores such as Hobby Lobby you can buy a roll of copper at 36 gauge (the higher the gauge, the thinner the sheet). I have used this to good effect. Pushing from the back is called "repousse" and pushing from the front is called "chasing." If you look up chasing and repousse tools on Google, you'll find places that sell all sorts of tools for this type of art. I'd recommend Mettleworks.com since they have sets as well as individual tools. Do some reading online before you decide which tools to buy. -

QuestionWhat is the thickness of the metal used?

Community AnswerYou can use many different gauges. 20 is a good thickness to use, or you may want to go even higher to 22 or 24. Just remember that different gauge metal sheets crack at different levels of relief, so make adjustments as necessary.

Community AnswerYou can use many different gauges. 20 is a good thickness to use, or you may want to go even higher to 22 or 24. Just remember that different gauge metal sheets crack at different levels of relief, so make adjustments as necessary. -

QuestionWhat weight of aluminum should I use to make tin ceiling tiles?

GabrielCommunity AnswerYou definetly want to keep the weight of the ceiling tiles as light as possible. You would need something clos to the thickness of an aluminum can. One great candidate for making an excellent embossing, engraving and stamped edges would be a roll of aluminum sheet metal flashing used for roofing and protecting surrounding bath and kitchen sink walls, corners and edges from moisture.

GabrielCommunity AnswerYou definetly want to keep the weight of the ceiling tiles as light as possible. You would need something clos to the thickness of an aluminum can. One great candidate for making an excellent embossing, engraving and stamped edges would be a roll of aluminum sheet metal flashing used for roofing and protecting surrounding bath and kitchen sink walls, corners and edges from moisture.

Warnings

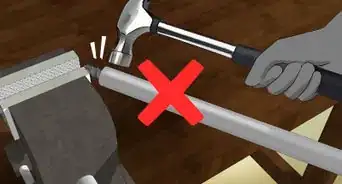

- The cut edges of a metal embossing sheet can be sharp. Take care when handling to avoid cutting your hands.⧼thumbs_response⧽

Things You'll Need

- Metal sheet

- Metal stylus

- Metal embossing tool

- Rubber mat

- Scissors

- Tape