This article was co-authored by wikiHow Staff. Our trained team of editors and researchers validate articles for accuracy and comprehensiveness. wikiHow's Content Management Team carefully monitors the work from our editorial staff to ensure that each article is backed by trusted research and meets our high quality standards.

There are 11 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 112,266 times.

Learn more...

Knowing the level of torque you’re applying to a nut is essential for the stability of a piece of machinery or structure. If you use too little torque, the nut may not be secure, and if you apply too much, you could strip the threads along the bolt. Luckily, several types of wrenches will help you determine how much torque you’re applying. The most common types of these tools are micrometer, beam, dial, and digital torque wrenches. If you use your torque wrench correctly, it should be simple to read it.

Steps

Reading a Micrometer Torque Wrench

-

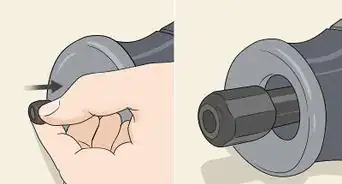

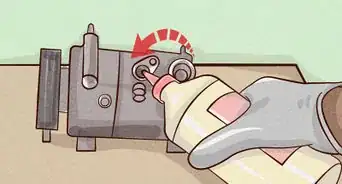

1Rotate the knob on the end of the handle counter-clockwise. Turning the knob on the end of the handle will loosen the torque wrench and allow you to rotate it. Loosen the knob before you try to adjust the torque settings.[1]

-

2Find the vertically listed numbers above the wrench handle. You should see 2 sets of vertical numbers on both sides of your torque wrench. One side of the wrench will be in foot-pounds or ft.-lbs., and the other set of numbers will be in Newton meters or Nm. These are both different units used to measure torque. The vertically listed numbers are usually called the main scale and represent the amount of torque your wrench is set to, to the nearest ten.[2]

- The numbers will have horizontal lines running next to them.

Advertisement -

3Find the numbers wrapped around the wrench’s handle. The numbers that wrap around the wrench’s handle are usually referred to as the micrometer. These numbers measure the second number in your torque measurement and allow you to set a more precise torque level.[3]

-

4Turn the handle on the wrench to adjust the torque setting. Turning the handle clockwise will increase the torque while turning it counterclockwise will reduce it. You’ll notice that as you rotate the handle on the wrench, the handle will move up and down while the numbers on the micrometer will rotate. Turning the handle will affect both the main scale and the micrometer scale at the same time.[4]

-

5Set the wrench for the precise torque you're seeking. Line up the vertical line on the handle of your wrench with the vertical line above each number on the micrometer to reach your desired setting.[5]

- For example, if your main scale is slightly above the 90-ft.-lbs. (122 Nm) horizontal line and the 3 on the micrometer lines up with the vertical line, it means that your wrench is set to 93 feet (28.3 m).-lbs. (126 Nm).

-

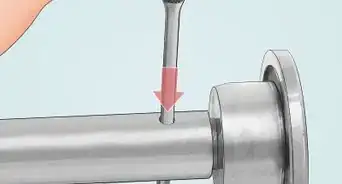

6Tighten the knob at the end of the torque wrench. Turn the knob at the end of the wrench handle clockwise. This will tighten the wrench and set the level of torque on the wrench. If you need to adjust the torque again, loosen the knob and turn the handles to the torque that you need.[6]

- Be careful when tightening the bolt because you could lose the measurement if you drop the wrench.

-

7Listen for the click while you work. As you use the wrench, you'll hear a click when you reach the set level of torque. So stop tightening when you hear that click![7]

- Store the wrench on the lowest torque setting so there isn’t tension on the mechanism.

Understanding the Numbers on a Beam or Dial Torque Wrench

-

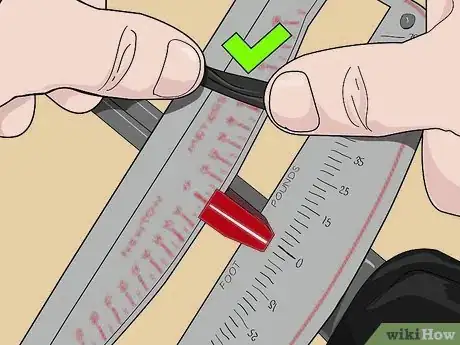

1Look at the meter at the bottom of the torque wrench. There should be a meter at the bottom of the wrench with numbers and an arrow. The numbers represent the amount of torque in either foot-pounds (ft.-lbs.) or Newton meters (Nm). Wherever the arrow is pointed designates the amount of torque that you’re applying to a lug or nut. In the stationary position, the wrench should read 0.[8]

-

2Turn the wrench around a nut or bolt and look at the arrow. As you turn the wrench around a nut or bolt, the arrow will move and represent the amount of torque you’re applying. For example, if you turn the wrench around the nut and it reads 30 lbs.-ft (40.7 Nm), that means you’re applying that level of torque to the nut. Apply force slowly to avoid damaging the bolt.[9]

- Read the arrow from directly above so you get an accurate reading.

- Some dial torque wrenches will have a memory arrow that follows the main arrow and stays at the highest level of torque. This makes it so that even if you disengage the wrench, you’ll know the max torque you were applying to the nut.

-

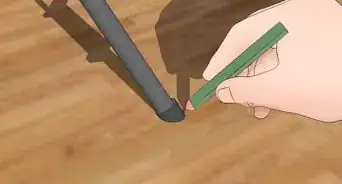

3Put a piece of tape on your desired torque line to read it more easily. There are a lot of lines and numbers on a beam or dial torque wrench, so it may be hard to see it without the tape. If your wrench doesn’t have a memory arrow, you can put a piece of tape next to the line of the desired amount of torque. Putting tape near the line will make the wrench easier to read.[10]

Using a Digital-Read Torque Wrench

-

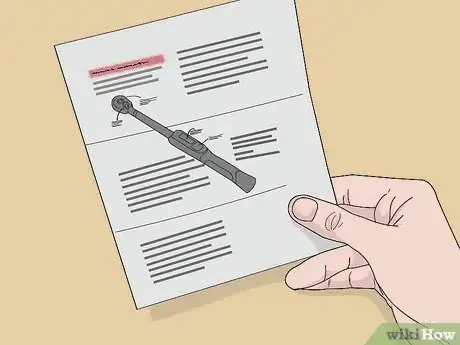

1Read the instruction manual that came with the wrench. The instruction manual will tell you how to adjust the torque settings on your wrench and will explain how to change the units of measure to read in either foot-pounds (ft.-lbs.) or Newton Meters (Nm).

- Clean the threads of the bolt you want to torque without any lubricant or tape.

- Some digital torque wrenches will also have other settings that affect the sounds and vibration levels.[11]

-

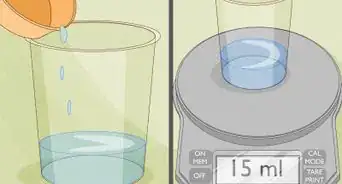

2Use the arrow keys to set a designated amount of torque. Press the up or down arrow to change the torque setting on the wrench. Continue to modify the numbers until you hit your desired level of torque.[12]

-

3Set the tolerance parameters with the % key. Some electronic torque wrenches will have tolerance parameters that will help you with precision. These parameters allow you to set a warning on your wrench before it reaches the desired torque. For example, if you set the tolerance parameters to 10%, the wrench will start lighting up and vibrating when you're within 10% of your desired torque. Set the tolerance parameters by hitting the % key, then using the arrow keys to change the percentage.[13]

- Use this setting if you need precise torque.

-

4Stop turning the wrench when it lights up or makes a noise. When you reach the amount of torque you need, the wrench will make a sound, light up, or vibrate. Stop turning the nut when this happens.[14]

References

- ↑ https://manuals.harborfreight.com/manuals/61000-61999/61277.pdf

- ↑ https://www.tekton.com/manuals/manual_24330.pdf

- ↑ https://manuals.harborfreight.com/manuals/61000-61999/61277.pdf

- ↑ https://www.youtube.com/watch?v=AriiR1i0DmI&t=4m41s

- ↑ https://homesteady.com/how-4814062-read-torque-wrench.html

- ↑ https://manuals.harborfreight.com/manuals/61000-61999/61277.pdf

- ↑ https://homesteady.com/how-4814062-read-torque-wrench.html

- ↑ https://www.youtube.com/watch?v=Eo2sq9BIC_8&t=1m45s

- ↑ https://www.youtube.com/watch?v=Eo2sq9BIC_8&t=2m2s