Turboprop

A turboprop is a turbine engine that drives an aircraft propeller.[1]

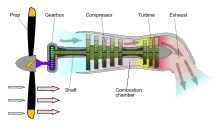

A turboprop consists of an intake, reduction gearbox, compressor, combustor, turbine, and a propelling nozzle.[2] Air enters the intake and is compressed by the compressor. Fuel is then added to the compressed air in the combustor, where the fuel-air mixture then combusts. The hot combustion gases expand through the turbine stages, generating power at the point of exhaust. Some of the power generated by the turbine is used to drive the compressor and electric generator. The gases are then exhausted from the turbine. In contrast to a turbojet or turbofan, the engine's exhaust gases do not provide enough power to create significant thrust, since almost all of the engine's power is used to drive the propeller.[3]

Technological aspects

Exhaust thrust in a turboprop is sacrificed in favor of shaft power, which is obtained by extracting additional power (beyond that necessary to drive the compressor) from turbine expansion. Owing to the additional expansion in the turbine system, the residual energy in the exhaust jet is low.[4][5][6] Consequently, the exhaust jet produces about 10% of the total thrust.[7] A higher proportion of the thrust comes from the propeller at low speeds and less at higher speeds.[8]

Turboprops have bypass ratios of 50–100,[9][10] although the propulsion airflow is less clearly defined for propellers than for fans.[11][12]

The propeller is coupled to the turbine through a reduction gear that converts the high RPM/low torque output to low RPM/high torque. This can be of two primary designs, free-turbine and fixed. A free-turbine turboshaft found on the Pratt & Whitney Canada PT6, where the gas generator is not connected to the propeller. This allows for propeller strike or similar damage to occur without damaging the gas generator and allowing for only the power section (turbine and gearbox) to be removed and replaced in such an event, and also allows for less stress on the start during engine ground starts. Whereas a fixed shaft has the gearbox and gas generator connected, such as on the Honeywell TPE331.

The propeller itself is normally a constant-speed (variable pitch) propeller type similar to that used with larger aircraft reciprocating engines, except that the propeller-control requirements are very different.[13] Due to the turbine engines slow response to power inputs, particularly at low speeds, the propeller has a greater range of selected travel in order to make rapid thrust changes, notably for taxi, reverse, and other ground operations.[14] The propeller has 2 modes, Alpha and Beta. Alpha is the mode for all flight operations including takeoff. Beta, a mode typically consisting of zero to negative thrust, is used for all ground operations aside from takeoff.[14] The Beta mode is further broken down into 2 additional modes, Beta for taxi and Beta plus power. Beta for taxi as the name implies is used for taxi operations and consists of all pitch ranges from the lowest alpha range pitch, all the way down to zero pitch, producing very little to zero-thrust and is typically accessed by moving the power lever to a beta for taxi range. Beta plus power is a reverse range and produces negative thrust, often used for landing on short runways where the aircraft would need to rapidly slow down, as well as backing operations and is accessed by moving the power lever below the beta for taxi range.[14] Due to the pilot not being able to see out of the rear of the aircraft for backing and the amount of debris reverse stirs up, manufacturers will often limit the speeds beta plus power may be used and restrict its use on unimproved runways.[14] Feathering of these propellers is performed by the propeller control lever.[14]

The constant-speed propeller is distinguished from the reciprocating engine constant-speed propeller by the control system. The turboprop system consists of 3 propeller governors, a governor, and overspeed governor, and a fuel-topping governor.[14] The governor works in much the same way a reciprocating engine propeller governor works, though a turboprop governor may incorporate beta control valve or beta lift rod for beta operation and is typically located in the 12 o'clock position.[14] There are also other governors that are included in addition depending on the model, such as an overspeed and fuel topping governor on a Pratt & Whitney Canada PT6, and an under-speed governor on a Honeywell TPE331.[14] The turboprop is also distinguished from other kinds of turbine engine in that the fuel control unit is connected to the governor to help dictate power.

To make the engine more compact, reverse airflow can be used. On a reverse-flow turboprop engine, the compressor intake is at the aft of the engine, and the exhaust is situated forward, reducing the distance between the turbine and the propeller.[15]

Unlike the small-diameter fans used in turbofan engines, the propeller has a large diameter that lets it accelerate a large volume of air. This permits a lower airstream velocity for a given amount of thrust. Since it is more efficient at low speeds to accelerate a large amount of air by a small degree than a small amount of air by a large degree,[16][17] a low disc loading (thrust per unit disc area) increases the aircraft's energy efficiency, and this reduces the fuel use.[18][19]

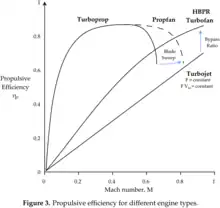

Propellers work well until the flight speed of the aircraft is high enough that the airflow past the blade tips reaches the speed of sound. Beyond that speed, the proportion of the power that drives the propeller that is converted to propeller thrust falls dramatically. For this reason turboprop engines are not commonly used on aircraft[4][5][6] that fly faster than 0.6–0.7 Mach,[7] with some exceptions such as the Tupolev Tu-95. However, propfan engines, which are very similar to turboprop engines, can cruise at flight speeds approaching 0.75 Mach. To maintain propeller efficiency across a wide range of airspeeds, turboprops use constant-speed (variable-pitch) propellers. The blades of a constant-speed propeller increase their pitch as aircraft speed increases. Another benefit of this type of propeller is that it can also be used to generate reverse thrust to reduce stopping distance on the runway. Additionally, in the event of an engine failure, the propeller can be feathered, thus minimizing the drag of the non-functioning propeller.[20]

While the power turbine may be integral with the gas generator section, many turboprops today feature a free power turbine on a separate coaxial shaft. This enables the propeller to rotate freely, independent of compressor speed.[21]

History

.svg.png.webp)

Alan Arnold Griffith had published a paper on compressor design in 1926. Subsequent work at the Royal Aircraft Establishment investigated axial compressor-based designs that would drive a propeller. From 1929, Frank Whittle began work on centrifugal compressor-based designs that would use all the gas power produced by the engine for jet thrust.[22]

The world's first turboprop was designed by the Hungarian mechanical engineer György Jendrassik.[23] Jendrassik published a turboprop idea in 1928, and on 12 March 1929 he patented his invention. In 1938, he built a small-scale (100 Hp; 74.6 kW) experimental gas turbine.[24] The larger Jendrassik Cs-1, with a predicted output of 1,000 bhp, was produced and tested at the Ganz Works in Budapest between 1937 and 1941. It was of axial-flow design with 15 compressor and 7 turbine stages, annular combustion chamber. First run in 1940, combustion problems limited its output to 400 bhp. Two Jendrassik Cs-1s were the engines for the world's first turboprop aircraft – the Varga RMI-1 X/H. This was a Hungarian fighter-bomber of WWII which had one model completed, but before its first flight it was destroyed in a bombing raid.[25][26] In 1941, the engine was abandoned due to war, and the factory converted to conventional engine production.

The first mention of turboprop engines in the general public press was in the February 1944 issue of the British aviation publication Flight, which included a detailed cutaway drawing of what a possible future turboprop engine could look like. The drawing was very close to what the future Rolls-Royce Trent would look like.[27] The first British turboprop engine was the Rolls-Royce RB.50 Trent, a converted Derwent II fitted with reduction gear and a Rotol 7 ft 11 in (2.41 m) five-bladed propeller. Two Trents were fitted to Gloster Meteor EE227 — the sole "Trent-Meteor" — which thus became the world's first turboprop-powered aircraft, albeit a test-bed not intended for production.[28][29] It first flew on 20 September 1945. From their experience with the Trent, Rolls-Royce developed the Rolls-Royce Clyde, the first turboprop engine to receive a type certificate for military and civil use,[30] and the Dart, which became one of the most reliable turboprop engines ever built. Dart production continued for more than fifty years. The Dart-powered Vickers Viscount was the first turboprop aircraft of any kind to go into production and sold in large numbers.[31] It was also the first four-engined turboprop. Its first flight was on 16 July 1948. The world's first single engined turboprop aircraft was the Armstrong Siddeley Mamba-powered Boulton Paul Balliol, which first flew on 24 March 1948.[32]

The Soviet Union built on German World War II turboprop preliminary design work by Junkers Motorenwerke, while BMW, Heinkel-Hirth and Daimler-Benz also worked on projected designs.[33] While the Soviet Union had the technology to create the airframe for a jet-powered strategic bomber comparable to Boeing's B-52 Stratofortress, they instead produced the Tupolev Tu-95 Bear, powered with four Kuznetsov NK-12 turboprops, mated to eight contra-rotating propellers (two per nacelle) with supersonic tip speeds to achieve maximum cruise speeds in excess of 575 mph, faster than many of the first jet aircraft and comparable to jet cruising speeds for most missions. The Bear would serve as their most successful long-range combat and surveillance aircraft and symbol of Soviet power projection throughout the end of the 20th century. The USA used turboprop engines with contra-rotating propellers, such as the Allison T40, on some experimental aircraft during the 1950s. The T40-powered Convair R3Y Tradewind flying-boat was operated by the U.S. Navy for a short time.

The first American turboprop engine was the General Electric XT31, first used in the experimental Consolidated Vultee XP-81.[34] The XP-81 first flew in December 1945, the first aircraft to use a combination of turboprop and turbojet power. The technology of Allison's earlier T38 design evolved into the Allison T56, used to power the Lockheed Electra airliner, its military maritime patrol derivative the P-3 Orion, and the C-130 Hercules military transport aircraft.

The first turbine-powered, shaft-driven helicopter was the Kaman K-225, a development of Charles Kaman's K-125 synchropter, which used a Boeing T50 turboshaft engine to power it on 11 December 1951.[35]

December 1963 saw the first delivery of Pratt & Whitney Canada's Pt6 turboprop engine for the then Beechcraft 87, soon to become Beechcraft King Air.[36]

1964 saw the first deliveries of the Garrett AiResearch TPE331, (now owned by Honeywell Aerospace) on the Mitsubishi MU-2, making it the fastest turboprop aircraft for that year.[37]

Usage

In contrast to turbofans, turboprops are most efficient at flight speeds below 725 km/h (450 mph; 390 knots) because the jet velocity of the propeller (and exhaust) is relatively low. Modern turboprop airliners operate at nearly the same speed as small regional jet airliners but burn two-thirds of the fuel per passenger.[38]

Compared to piston engines, their greater power-to-weight ratio (which allows for shorter takeoffs) and reliability can offset their higher initial cost, maintenance and fuel consumption. As jet fuel can be easier to obtain than avgas in remote areas, turboprop-powered aircraft like the Cessna Caravan and Quest Kodiak are used as bush airplanes.

Turboprop engines are generally used on small subsonic aircraft, but the Tupolev Tu-114 can reach 470 kn (870 km/h; 540 mph). Large military aircraft, like the Tupolev Tu-95, and civil aircraft, such as the Lockheed L-188 Electra, were also turboprop powered. The Airbus A400M is powered by four Europrop TP400 engines, which are the second most powerful turboprop engines ever produced, after the 11 MW (15,000 hp) Kuznetsov NK-12.

In 2017, the most widespread turboprop airliners in service were the ATR 42/72 (950 aircraft), Bombardier Q400 (506), De Havilland Canada Dash 8-100/200/300 (374), Beechcraft 1900 (328), de Havilland Canada DHC-6 Twin Otter (270), Saab 340 (225).[40] Less widespread and older airliners include the BAe Jetstream 31, Embraer EMB 120 Brasilia, Fairchild Swearingen Metroliner, Dornier 328, Saab 2000, Xian MA60, MA600 and MA700, Fokker 27 and 50.

Turboprop business aircraft include the Piper Meridian, Socata TBM, Pilatus PC-12, Piaggio P.180 Avanti, Beechcraft King Air and Super King Air. In April 2017, there were 14,311 business turboprops in the worldwide fleet.[41]

Reliability

Between 2012 and 2016, the ATSB observed 417 events with turboprop aircraft, 83 per year, over 1.4 million flight hours: 2.2 per 10,000 hours. Three were "high risk" involving engine malfunction and unplanned landing in single‑engine Cessna 208 Caravans, four "medium risk" and 96% "low risk". Two occurrences resulted in minor injuries due to engine malfunction and terrain collision in agricultural aircraft and five accidents involved aerial work: four in agriculture and one in an air ambulance.[42]

Current engines

Jane's All the World's Aircraft. 2005–2006.

References

- Administration, Federal Aviation (3 November 2009). Pilot's Handbook of Aeronautical Knowledge. Skyhorse Publishing Inc. ISBN 978-1-60239-780-4.

- "Aviation Glossary – Turboprop". dictionary.dauntless-soft.com. Retrieved 7 July 2019.

- Rathore, Mahesh. Thermal Engineering. Tata McGraw-Hill Education. p. 968.

- Hall, Nancy (2021). "Turboprop Engine". Glenn Research Center. NASA. Retrieved 14 March 2023.

- Hall, Nancy (2021). "Turboprop Thrust". Glenn Research Center. NASA. Retrieved 14 March 2023.

- "Variations of Jet Engines". smu.edu. Retrieved 31 August 2016.

- ""The turbofan engine Archived 18 April 2015 at the Wayback Machine", page 7. SRM Institute of Science and Technology, Department of aerospace engineering.

- J. Russell (2 August 1996). Performance and Stability of Aircraft. Butterworth-Heinemann. p. 16. ISBN 0080538649.

- Ilan Kroo and Juan Alonso. "Aircraft Design: Synthesis and Analysis, Propulsion Systems: Basic Concepts Archived 18 April 2015 at the Wayback Machine" Stanford University School of Engineering, Department of Aeronautics and Astronautics Main page Archived 23 February 2001 at the Wayback Machine

- Prof. Z. S. Spakovszky. "11.5 Trends in thermal and propulsive efficiency" MIT turbines, 2002. Thermodynamics and Propulsion

- Hall, Nancy (2021). "Propeller Thrust". Glenn Research Center. NASA. Retrieved 14 March 2023.

- Walsh, Philip; Fletcher, Paul (2008). Gas Turbine Performance. John Wiley and Sons. p. 36. ISBN 9781405151030.

- Airscrews For Turbines,Fairhurst, Flight magazine, 10 November 1949, p.609

- A&P Powerplant Textbook (3rd ed.). Jeppeson Company. 2011. ISBN 0884873382.

- Martin, Swayne (16 May 2019). "How A Turboprop Engine Works". Boldmethod. Archived from the original on 6 November 2021. Retrieved 6 November 2021.

- Paul Bevilaqua. The shaft driven Lift Fan propulsion system for the Joint Strike Fighter Archived 5 June 2011 at the Wayback Machine page 3. Presented 1 May 1997. DTIC.MIL Word document, 5.5 MB. Retrieved 25 February 2012.

- Bensen, Igor B. "How They Fly". Archived from the original on 20 April 2001. Retrieved 31 May 2023.

{{cite web}}: CS1 maint: unfit URL (link) - Johnson, Wayne (1 January 1994). Helicopter Theory. Courier Corporation. ISBN 978-0-486-68230-3.

- Stepniewski, Wieslaw Zenon; Keys, C. N. (1 January 1984). Rotary-wing Aerodynamics. Courier Corporation. ISBN 978-0-486-64647-3.

- "Operating Propellers during Landing & Emergencies". experimentalaircraft.info. Retrieved 8 July 2019.

- "An Engine Ahead of Its Time". PT6 Nation. Pratt & Whitney Canada.

- Gunston Jet, p. 120

- Gunston World, p.111

- "Magyar feltalálók és találmányok – JENDRASSIK GYÖRGY (1898–1954)". SZTNH. Retrieved 31 May 2012.

- "The Jendrassik CS-1: The World's First Turboprop Engine". www.tailsthroughtime.com. Retrieved 4 September 2023.

- "RMI / Repülő Muszaki Intézet Varga RMI-1/ X / H". Retrieved 4 September 2023.

- "Our Contribution – How Flight Introduced and Made Familiar With Gas Turbines and Jet Propulsion" Flight, 11 May 1951, p. 569.

- James p. 251-2

- Green p.18-9

- "rolls-royce trent – armstrong siddeley – 1950–2035 – Flight Archive". Flightglobal. Retrieved 31 August 2016.

- Green p.82

- Green p.81

- Turbojet History And Development 1930-1960 Volume 1 Great Britain And Germany, Antony L. Kay 2007, ISBN 978 1 86126 912 6, various pages

- Green p.57

- "Smithsonian National Air and Space Museum – Collections – Kaman K-225 (Long Description)". National Air and Space Museum. Archived from the original on 4 March 2016. Retrieved 4 April 2013.

- "PT6 60 YEARS - Pratt & Whitney". www.pwc.ca. Retrieved 27 June 2023.

- "Evolution of the Honeywell TPE331". aerospace.honeywell.com. Retrieved 27 June 2023.

- "More turboprops coming to the market – maybe". CAPA – Centre for Aviation. 9 July 2010.

- "Beechcraft King Air 350i rolls out improved situational awareness, navigation" (Press release). Textron Aviation. 30 May 2018.

- "787 stars in annual airliner census". Flightglobal. 14 August 2017.

- "Business Aviation Market Update Report" (PDF). AMSTAT, Inc. April 2017.

- Gordon Gilbert (25 June 2018). "ATSB Study Finds Turboprop Engines Safe, Reliable".

- "The H-Series Engine | Engines | B&GA | GE Aviation". www.geaviation.com. Retrieved 1 June 2016.

- , PragueBest s.r.o. "History | GE Aviation". www.geaviation.cz. Archived from the original on 29 October 2017. Retrieved 1 June 2016.

{{cite web}}: External link in|last=

Bibliography

- Green, W. and Cross, R.The Jet Aircraft of the World (1955). London: MacDonald

- Gunston, Bill (2006). The Development of Jet and Turbine Aero Engines, 4th Edition. Sparkford, Somerset, England, UK: Patrick Stephens, Haynes Publishing. ISBN 0-7509-4477-3.

- Gunston, Bill (2006). World Encyclopedia of Aero Engines, 5th Edition. Phoenix Mill, Gloucestershire, England, UK: Sutton Publishing Limited. ISBN 0-7509-4479-X.

- James, D.N. Gloster Aircraft since 1917 (1971). London: Putnam & Co. ISBN 0-370-00084-6

Further reading

- Van Sickle, Neil D.; et al. (1999). "Turboprop Engines". Van Sickle's modern airmanship. McGraw-Hill Professional. p. 205. ISBN 978-0-07-069633-4.

External links

- Jet Turbine Planes by LtCol Silsbee USAAF, Popular Science, December 1945, first article on turboprops printed

- Wikibooks: Jet propulsion

- "Development of the Turboprop" – a 1950 Flight article on UK and US turboprop engines