Wind-assisted propulsion

Wind assisted propulsion is the practice of decreasing the fuel consumption of a merchant vessel through the use of sails or some other wind capture device. Sails used to be the primary means of propelling ships, but with the advent of the steam engine and the diesel engine, sails came to be used for recreational sailing only. In recent years with increasing fuel costs and an increased focus on reducing emissions, there has been increased interest in harnessing the power of the wind to propel commercial ships.

A key barrier for the implementation of any decarbonisation technology and in particular of wind-assisted ones, is frequently discussed in the academia and the industry is the availability of capital. On the one hand, shipping lenders have been reducing their commitments overall[1] while on the other hand, low-carbon newbuilds as well as retrofit projects entail higher-than-usual capital expenditure (CapEx).[2][3][4] Therefore, research effort is directed towards the development of shared economy and leasing business models, where benefits from reduced consumption of fossil fuels as well as gains from carbon allowances or reduced levies are shared among users, technology providers and operators.[5][6]

Design

The mechanical means of converting the kinetic energy of the wind into thrust for a ship is the subject of much recent study. Where early ships designed primarily for sailing were designed around the sails that propelled them, commercial ships are now designed largely around the cargo that they carry, requiring a large clear deck and minimal overhead rigging in order to facilitate cargo handling. Another design consideration in designing a sail propulsion system for a commercial ship is that in order for it to be economically advantageous it cannot require a significantly larger crew to operate and it cannot compromise the stability of the ship. Taking into account these design criteria, three main concepts have emerged as the leading designs for wind-assisted propulsion: the “Wing Sail Concept,” the “Kite Sail,” and the “Flettner Rotor.”

Wingsail

As a result of rising oil prices in the 1980s, the US government commissioned a study on the economic feasibility of using wind assisted propulsion to reduce the fuel consumption of ships in the US Merchant Marine. This study considered several designs and concluded that a wingsail would be the most effective. The wingsail option studied consisted of an automated system of large rectangular solid sails supported by cylindrical masts. These would be symmetrical sails, which would allow a minimal amount of handling to maintain the sail orientation for different wind angles; however, this design was less efficient. A small freighter was outfitted with this system to evaluate its actual fuel gains, with the result that it was estimated to save between 15–25% of the vessel's fuel.[7]

Kite sail

The kite sail concept has recently received a lot of interest. This rig consists of flying a gigantic kite from the bow of a ship using the traction developed by the kite to assist in pulling the ship through the water. Other concepts that have been explored were designed to have the kite rig alternately pull out and retract on a reel, driving a generator. The kite used in this setup is similar to the kites used by recreational kiteboarders, on a much larger scale. This design also allows users to expand its scale by flying multiple kites in a stacked arrangement.

The idea of using kites was, in 2012, the most popular form of wind-assisted propulsion on commercial ships, largely due to the low cost of retrofitting the system to existing ships, with minimal interference with existing structures. This system also allows a large amount of automation, using computer controls to determine the ideal kite angle and position. Using a kite allows the capture of wind at greater altitudes, where wind speed is higher and more consistent.[8] This system has seen use on several ships, with the most notable in 2009 being MS Beluga Skysails, a merchant ship chartered by the US Military Sealift Command to evaluate the claims of efficiency and the feasibility of fitting this system to other ships.[9]

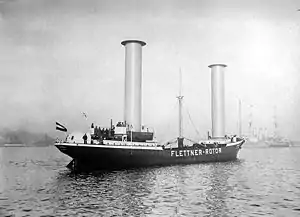

Flettner rotor

The third design considered is the Flettner rotor. This is a large cylinder mounted upright on a ship's deck and mechanically spun. The effect of this spinning area in contact with the wind flowing around it creates a thrust effect that is used to propel the ship. Flettner Rotors were invented in the 1920s and have seen limited use since then. In 2010 a 10,000 dwt cargo ship was equipped with four Flettner Rotors to evaluate their role in increasing fuel efficiency. Since then, several cargo ships and a passenger ferry have been equipped with rotors.

The only parameter of the Flettner Rotor requiring control is the rotational speed of the rotor, meaning this method of wind propulsion requires very little operator input. In comparison to kite sails, Flettner rotors often offer considerable efficiency gains when compared to the size of a sail or kite, versus the size of the rotor and prevailing wind conditions.[10]

Examples of 2018 Flettner rotor installations include :

- Cruise ferry Viking Grace became the first passenger vessel with a rotor.[11]

- The liquid bulk tanker Maersk Pelican was retrofitted with two rotors.[12][13]

- The ultramax bulk carrier Afros received four rotors, which can be moved aside during port operations.[14]

Implementation

The efficiency gains of these three propulsion assistance mechanisms are typically around 15–20% depending on the size of the system. As of 2009, shipping companies had been hesitant to install untested equipment.[15] As of 2019, several initiatives were looking into the feasibility of cost-effective wind propulsion for commercial ships, including the Swedish Oceanbird concept for using wing sails,[16] the Japanese Wind Challenger Project,[17] and several coordinating associations.[17]

See also

- Pyxis Ocean, a bulk carrier retrofitted with wind-propulsion technology

- Viking Grace, a rotor assisted cruise ship

- Wind Surf, a wind assisted cruise ship

- Turbosail – Type of ship propulsion system

- DynaRig – Modern form of sailing ship rigging

- Hydrogen-powered ship

- Nuclear marine propulsion

- Internal drive propulsion

- Integrated electric propulsion

- Combined nuclear and steam propulsion

- Astern propulsion

- Marine propulsion

- Air-independent propulsion

References

- Furber, Sophia (21 October 2019). "Global shipping finance tanks, but Greek and French banks are buoyant". Retrieved 20 November 2020.

- Halim, Ronald; Kirstein, Lucie; Merk, Olaf; Martinez, Luis (2018-06-29). "Decarbonization Pathways for International Maritime Transport: A Model-Based Policy Impact Assessment". Sustainability. 10 (7): 2243. doi:10.3390/su10072243. ISSN 2071-1050.

- Schinas, Orestis; Ross, Harm Hauke; Rossol, Tobias Daniel (2018-12-01). "Financing green ships through export credit schemes". Transportation Research Part D: Transport and Environment. 65: 300–311. doi:10.1016/j.trd.2018.08.013. ISSN 1361-9209. S2CID 116208589.

- Schinas, Orestis (2018), "Financing Ships of Innovative Technology", Finance and Risk Management for International Logistics and the Supply Chain, Elsevier, pp. 167–192, doi:10.1016/b978-0-12-813830-4.00007-1, ISBN 978-0-12-813830-4, retrieved 2020-11-20

- Schinas, Orestis; Metzger, Daniel (2019-04-01). "A pay-as-you-save model for the promotion of greening technologies in shipping". Transportation Research Part D: Transport and Environment. 69: 184–195. doi:10.1016/j.trd.2019.01.018. ISSN 1361-9209. S2CID 115879277.

- Metzger, Daniel; Schinas, Orestis (2019-12-01). "Fuzzy real options and shared savings: Investment appraisal for green shipping technologies". Transportation Research Part D: Transport and Environment. 77: 1–10. doi:10.1016/j.trd.2019.09.016. ISSN 1361-9209. S2CID 208839914.

- Wind Ship Development Corporation (1981). Wind Propulsion for ships of the American merchant marine. Washington, DC: U.S. Department of Commerce. hdl:2027/mdp.39015000478001.

- Rizzuto, E. (2012). Sustainable Maritime Transportation and Exploitation of Sea Resources. London, UK: CRC Press

- Konrad, John. (2009, April). Mariners Weather Log Vol.53 No. 1. Retrieved from U.S. Department of Commerce website: http://www.vos.noaa.gov/MWL/apr_09/skysails.shtml

- Traut Michael. (2014, January). Propulsive power contribution of a kite and a Flettner rotor on selected shipping routes. Applied Energy, 113, 362–372.

- "Viking Line Installs Rotor Sail on Cruise Ferry". The Maritime Executive. April 11, 2018. Retrieved 2020-11-20.

- "Flettner Rotor Trial Delivers Real-World Fuel Savings". The Maritime Executive. October 25, 2019. Retrieved 2020-11-20.

- Kundu, Ankur (January 29, 2021). "Maersk Tankers Sells its First Wind-Assisted Vessel". The Maritime Executive. Retrieved 2021-07-23.

- Roker, Stephanie (2018-12-14). "Ultramax bulker installed with wind engines; awarded Ship of the Year 2018". Dry Bulk. Retrieved 2021-07-23.

- "Mariners Weather Log Vol. 53, No. 1, April 2009". www.vos.noaa.gov. Retrieved 2023-08-22.

- Levin, Tim. "This cargo-ship concept is powered by gigantic wings and wants to reduce emissions by 90% — check out 'Oceanbird'". Business Insider. Retrieved 2020-10-08.

- Spross, Jeff (February 26, 2019). "Why cargo ships might (literally) sail the high seas again". The Week. Retrieved 2023-08-22.