Zinc dithiophosphate

Zinc dialkyldithiophosphates (often referred to as ZDDP) are a family of coordination compounds developed in the 1940s that feature zinc bound to the anion of a dialkyldithiophosphoric salt (e.g., ammonium diethyl dithiophosphate).[1] These uncharged compounds are not salts. They are soluble in nonpolar solvents, and the longer-chain derivatives easily dissolve in mineral and synthetic oils used as lubricants. They come under CAS number . In aftermarket oil additives, the percentage of ZDDP ranges approximately between 2 and 15%.[2] Zinc dithiophosphates have many names, including ZDDP, ZnDTP, and ZDP.

2.png.webp)

Applications

The main application of ZDDPs are as anti-wear additives in lubricants including greases, hydraulic oils, and motor oils. ZDDPs also act as corrosion inhibitors and antioxidants. Concentrations in lubricants range from 600 ppm for modern, energy-conserving low-viscosity oils to 2000 ppm in some racing oils.

It has been reported that zinc and phosphorus emissions may damage catalytic converters and standard formulations of lubricating oils for gasoline engines now have reduced amounts of the additive due to the API limiting the concentration of this additive in new API SM and SN oils; however, this affects only 20- and 30-grade "ILSAC" oils. Grades 40 and higher have no regulation regarding the concentration of ZDDP, except for diesel oils meeting the API CJ-4 specification which have had the level of zddp reduced slightly, although most diesel Heavy-Duty Engine oils still have a higher concentration of this additive.[3] Crankcase oils with reduced ZDDP have been cited as causing damage to, or failure of, classic/collector car flat-tappet camshafts and lifters which undergo very high boundary layer pressures and/or shear forces at their contact faces, and in other regions such as main bearings, and piston rings and pins. Roller camshafts/followers are more commonly used to reduce camshaft lobe friction in modern engines.[4] There are additives, such as STP Oil Treatment, and some racing oils such as PurOl, PennGrade 1, and Valvoline VR-1, Kixx Hydraulic Oil which are available in the retail market with the necessary amount of ZDDP for engines using increased valve spring pressures.

Tribofilm formation mechanism

Various mechanisms have been proposed for how ZDDP forms protective tribofilms on solid surfaces.[1] In-situ atomic-force microscopy (AFM) experiments show that the growth of ZDDP tribofilms increases exponentially with both the applied pressure and temperature, consistent with a stress-promoted thermal activation reaction rate model.[5] Subsequently, experiments with negligible solid-solid contact demonstrated that film formation rate depends on the applied shear stress.[6]

Synthesis and structure

With the formula Zn[(S2P(OR)2]2, zinc dithiophosphate features diverse R groups. Typically, R is a branched or linear alkyl between 1-14 carbons in length. Examples include 2-butyl, pentyl, hexyl, 1,3-dimethylbutyl, heptyl, octyl, isooctyl (2-ethylhexyl), 6-methylheptyl, 1-methylpropyl, dodecylphenyl, and others. A mix of zinc dialkyl(C3-C6)dithiophosphates come under CAS number . A list of other examples with their CAS numbers is here.

Zinc dithiophosphate are produced in two steps. First phosphorus pentasulfide is treated with suitable alcohols (ROH) to give the dithiophosphoric acid. A wide variety of alcohols can be employed, which allows the lipophilicity of the final zinc product to be fine tuned. The resulting dithiophosphate is then neutralized by adding zinc oxide:[7][8]

- P2S5 + 4 ROH → 2 (RO)2PS2H + H2S

- 2 (RO)2PS2H + ZnO → Zn[(S2P(OR)2]2 + H2O

Structural chemistry

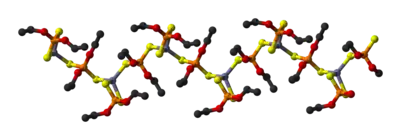

In Zn[(S2P(OR)2]2, the zinc has tetrahedral geometry. This monomeric compound Zn[(S2P(OR)2]2 exists in equilibrium with dimers, oligomers, and polymers [Zn[(S2P(OR)2]2]n (n > 1).[7] For example, zinc diethyldithiophosphate, Zn[(S2P(OEt)2]2, crystallizes as a polymeric solid consisting of linear chains.[9] Reaction of Zn[(S2P(OR)2]2 with additional zinc oxide gives rise to the oxygen-centered cluster, Zn4O[(S2P(OR)2]6, which adopts the structure seen for basic zinc acetate.[7]

References

- Spikes, H. (2004-10-01). "The History and Mechanisms of ZDDP". Tribology Letters. 17 (3): 469–489. doi:10.1023/B:TRIL.0000044495.26882.b5. ISSN 1023-8883. S2CID 7163944.

- Allyson M. Barnes, Keith D. Bartle and Vincent R. A. Thibo "A review of zinc dialkyldithiophosphates (ZDDPS): characterisation and role in the lubricating oil". Tribology International, 2001, pp. 389–395. doi:10.1016/S0301-679X(01)00028-7.

- "ZDDP Engine Oil – The Zinc Factor". Mustang Monthly. Retrieved 2009-09-19.

- McGean, Terry (1 March 2004). "Roller Camshafts – Roll With It". www.hotrod.com. Retrieved 26 January 2016.

- Gosvami, N. N.; Bares, J. A.; Mangolini, F.; Konicek, A. R.; Yablon, D. G.; Carpick, R. W. (2015-04-03). "Mechanisms of antiwear tribofilm growth revealed in situ by single-asperity sliding contacts" (PDF). Science. 348 (6230): 102–106. Bibcode:2015Sci...348..102G. doi:10.1126/science.1258788. ISSN 0036-8075. PMID 25765069.

- Zhang, Jie; Spikes, Hugh (2016-08-01). "On the Mechanism of ZDDP Antiwear Film Formation". Tribology Letters. 63 (2): 24. doi:10.1007/s11249-016-0706-7. ISSN 1023-8883.

- D. Johnson and J. Hils (2013). "Phosphate Esters, Thiophosphate Esters and Metal Thiophosphates as Lubricant Additives". Lubricants. 1 (4): 132–148. doi:10.3390/lubricants1040132.

- Randolph A. McDonald (2003). "Zinc Dithiophosphates" (Google Books excerpt). In Leslie R. Rudnick (ed.). Lubricant Additives: Chemistry and Applications. CRC Press. ISBN 9780824747404.

- T. Ito; T. Igarashi; H. Hagihara (1969). "The crystal structure of metal diethyldithiophosphates. I. Zinc diethyldithiophosphate" (PDF). Acta Crystallogr. B. 25 (11): 2303–2309. doi:10.1107/S0567740869005619.