This article was co-authored by wikiHow Staff. Our trained team of editors and researchers validate articles for accuracy and comprehensiveness. wikiHow's Content Management Team carefully monitors the work from our editorial staff to ensure that each article is backed by trusted research and meets our high quality standards.

This article has been viewed 7,921 times.

Learn more...

A pump impeller resembles a propeller and is the component that rotates quickly to drive fluid through the pump. They’re commonly used in centrifugal pumps to move water for things like farming and city water plants, as well as many other industrial purposes. The impellers can get damaged or wear down over time, so you may need to find a replacement that fits exactly into place. To do this, you need to know the exact diameter of the impeller. Luckily, it’s really easy to measure the diameter, regardless of how many blades are on the impeller.

Steps

Finding the Diameter of an Even-Bladed Impeller

-

1Make sure the pump is turned off before you measure the impeller. If the impeller is still attached to the pump, it can cause serious injury if it starts to turn while you’re taking your measurements. Look for the power switch and make sure that the pump is off. Unplug the pump to be extra sure that the power is shut off.[1]

- If you’re measuring an impeller that isn’t attached to a pump, lay it down on a flat surface to make it measure to measure.

-

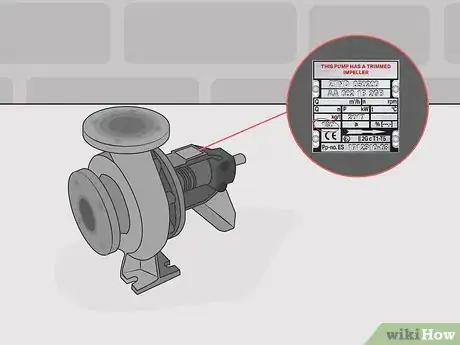

2Check to see if there’s an information plate on the outside of the pump. Some pump manufacturers will attach a metal plate to the casing of the pump that lists information and measurements. Look for the square plate and check to see if the diameter of the impeller is listed on it.[2]

- For instance, you may see a measurement that says “7” to indicate that the diameter of the impeller is 7 inches (18 cm).

- You could also look up the make and model of your pump to see if the impeller diameter is listed. However, impellers are sometimes trimmed down to affect the way the pump operates, so the measurements listed online may not be accurate.

Advertisement -

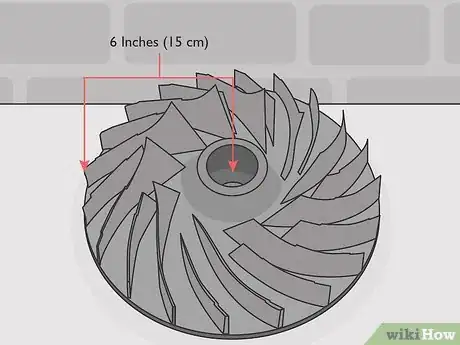

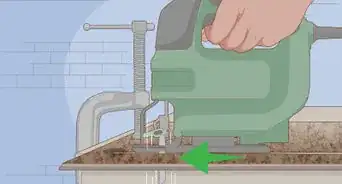

3Measure from the tip of 1 blade to the tip of the blade across from it. Use a tape measure and hold the end of it against the tip of 1 of the impeller’s blades. Stretch the tape measure all the way across the center of the impeller and line it up with the very end of the tip of the blade directly across from the first blade to find the diameter of the impeller.[3]

- For instance, if the distance between the tip of 1 blade and the tip of the blade across from it is 6 inches (15 cm), then that’s the diameter of the impeller.

Tip: For large impellers, have a friend hold the tape measure against the tip of the blade to keep it in place.

Calculating the Diameter of an Odd-Bladed Impeller

-

1Turn off the pump if the impeller is still attached. Pump impellers are designed to be powerful and rotate at a high speed, so if the impeller you’re measuring is already on the pump, double-check to make sure the power is shut off. Unplug the pump if you can to be extra cautious.[4]

- Make sure everyone around you knows you’re measuring the impeller so they don’t try to turn on the pump.

- Lay the impeller down on a flat surface if it’s not attached to the pump.

-

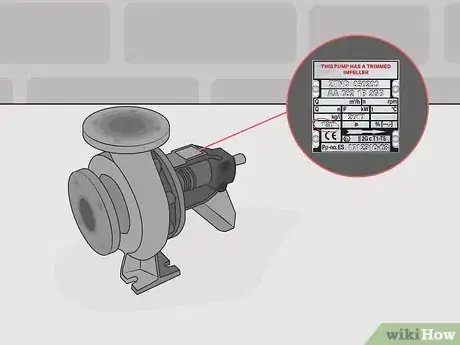

2Look for an information plate that lists the diameter of the impeller. The pump manufacturer may have included the diameter of the impeller on an information plate printed on the outside casing of the pump itself. Before you start to measure your impeller, take a look on the pump to see if the information is already listed there for you.[5]

- Look for a field on the information plate that says something like “Diameter” or “Dia.” and read the number in the field to find the diameter. For example, it may say something like 6.5 to indicate a diameter of 6.5 inches (17 cm).

- If there isn’t an information plate, no worries! You can measure the odd-numbered blades yourself.

-

3Stretch a tape measure from the shaft to the tip of 1 of the blades. Hold the end of a tape measure against the tip of 1 of the impeller blades. Since the impeller has an odd number of blades, there isn’t one directly across from it for you to measure with. Instead, stretch the tape measure to the center of the impeller, or the outer edge of the shaft if the impeller is attached to the pump.[6]

- The shaft is the rod in the center of the impeller that attaches it to the pump.

-

4Multiply the distance by 2 to find the length of 2 blades. Take the measurement of 1 blade and double it to make up for the fact that you’re unable to measure a blade directly across from it. Write down your measurements to use for your calculations.[7]

- For instance, if the measurement of 1 blade is 2 inches (5.1 cm), then you’d double it to get 4 inches (10 cm) as the length of 2 blades.

-

5Add the size of the shaft to your measurements to find the diameter. If the impeller is attached to the pump, you need to account for the size of the shaft in order to have an accurate measurement. Use your tape measure to measure the distance from the 1 edge of the shaft to the edge directly across from it. Add this measurement to your calculations to find the total diameter of your impeller.[8]

- So for example, if you have a blade measurement of 4 inches (10 cm), and the shaft measures .5 inches (1.3 cm), then the total diameter of the impeller is 4.5 inches (11 cm).

Note: If the impeller isn’t attached to a pump, measure from the tip of 1 blade to the center of the pump and double it to find the diameter.

Warnings

- Always make sure the pump is turned off before you try to measure an impeller attached to it.⧼thumbs_response⧽

Things You’ll Need

- Tape measure

References

- ↑ https://www.jandy.com/-/media/zodiac/global/downloads/h/h0311700.pdf

- ↑ https://www.ceienterprises.com/images/literature/stg/17-09-033.pdf

- ↑ https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19680017179.pdf

- ↑ https://www.jandy.com/-/media/zodiac/global/downloads/h/h0311700.pdf

- ↑ https://www.ceienterprises.com/images/literature/stg/17-09-033.pdf

- ↑ https://youtu.be/vwWfc6LY7kk?t=67

- ↑ https://youtu.be/vwWfc6LY7kk?t=75

- ↑ https://youtu.be/vwWfc6LY7kk?t=81