wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 20 people, some anonymous, worked to edit and improve it over time.

There are 7 references cited in this article, which can be found at the bottom of the page.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 100% of readers who voted found the article helpful, earning it our reader-approved status.

This article has been viewed 231,965 times.

Learn more...

If you need to fix a leaky joint in your plumbing, it might be economical to try it yourself, provided you've got the right materials. Learn how to join copper tubing using components commonly available in plumbing, heating, and refrigeration supply houses, and hardware stores such as Home Depot and Lowe's.

Steps

Getting the Proper Materials

-

1Get copper tubing of appropriate diameter. Copper tubing used for plumbing piping is available sized nominally, meaning that the outside diameter of the tubing is 1/8" (0.125 inches) larger than its stated size. In other words, 1" nominal copper tubing measures 1.125" inches in diameter.

- If you need to cut the pipe for your project, make sure that you use a tube cutter, clamping the pipe firmly and rotating the cutter around the pipe. It should take about 8 turns.[1]

- Ordering your supplies online? Check out wikiHow's coupon pages for Lowes and The Home Depot to scope out the potential savings.

-

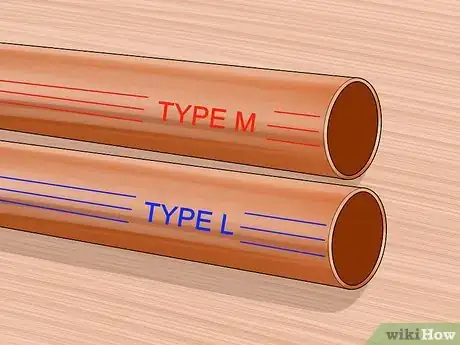

2Make sure the tubing is of the proper wall thickness for your project.[2] Most nominally-sized copper tubing is available in four weights, or wall thicknesses, which is color-coded. Typically, though, residential projects will involve copper tubing of either Type L or M.

- Type L tubing is marked with a blue tag and is typically the most commonly used in commercial/residential installations. Type M is marked red and has the lightest wall that can be used for a pressurized system.

Advertisement -

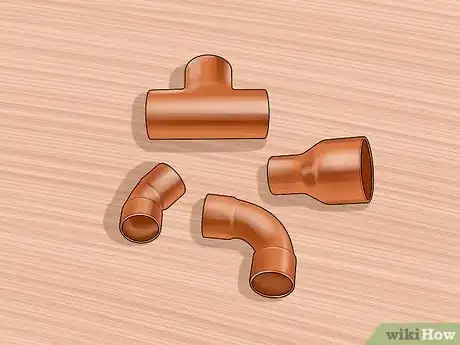

3Get the proper connectors and joints for the system you are building.[3] Depending on your project, you'll probably need some combination of the following:

- Male/Female adapters, which are used to join a solder pipe to a threaded pipe.

- Reducing adapters, which are used to go from a larger size pipe to a smaller size.

- Elbow joints, which are used to turn corners, typically 90 degree bends, but also available in 45 degree bends.

- Tees and crosses, which are used to join a branch tubing to the main tubing, using a tee, or two branches in the case of a "cross."

-

4Select solder. For potable water systems, lead-free solid core solder must be used.[4] It is typically 95/5 (95% tin and 5% antimony), or an alloy of tin and a small amount of copper and/or silver, commonly sold in one pound rolls of 1/8" diameter wire. Solder with lead must not be used for potable water systems.

-

5Obtain the appropriate solder flux. This is typically a jelly with a zinc chloride or rosin cleaning component used to cover the cleaned surfaces of the copper to be soldered before assembly and heating. It is the function of the flux, upon heating, to facilitate further cleaning, exclude atmospheric oxygen, prevent re-oxidation, and to aide in wetting out the solder.[5]

-

6Get a heat source. Typically, a traditional electric soldering iron won't be hot enough to work with copper tubing. You'll need a heat source of sufficient output capacity to heat the assembled fittings and tubing to a temperature above that required to melt the filler solder, typically 400 to 500 °F (204 to 260 °C). For this reason, a propane/air, or acetylene/air torch fitted with a tip of appropriate size is most often used. Clean, dry cotton rags and a spray bottle full of water will complete the necessary soldering materials.

Step Two: Soldering

-

1Prepare the pipe. Remove the copper oxide coating on both the outside of the tubing in the area to be inserted into the fitting, and the inside of the fitting itself. For this, you can use sandpaper, emery cloth, or specialty devices sold in stores for this purpose. All copper oxide must be thoroughly removed from both surfaces until they are both completely clean, with no dirt, grease, oil or other impediment which will interfere with the wetting out of the solder. If you don't, this will result in a leaky joint somewhere down the road.[6]

- Any small drips of water through the joint being soldered will prevent the process from working, resulting in a leaky fitting. If the system valves will not stop the drip completely before you start working, stop up the pipe with a piece of white bread, inserted in the tubing as far as possible away from the heated area. This will temporarily dam the water flow and will dissolve easily during the flushing operation suggested at the end of the job.

-

2Brush the cleaned surfaces with the solder flux as soon as possible after cleaning, and assemble the fitting and tubing. Apply flux to the inside and outside of the copper tubing.[7]

-

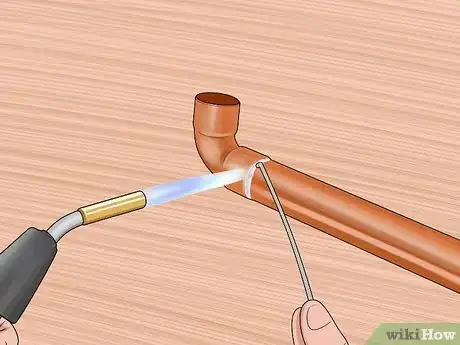

3Light the torch and adjust it so you have a blue flame. Move the end of the blue flame against the assembled fitting and tubing, moving it all around the components in the area into which solder must be placed. With constant movement at all times, heat slowly and uniformly while testing the melting point of the solder by touching the tip of the solder wire to the joint.[8]

- This will take some practice. Try holding the flame in your non-dominant hand and the solder in your writing hand. Remember, you're using the flame essentially to heat up the solder and melt it. You accomplish this by applying the flame to the copper tubing and then touching the solder to the joint. The heated tubing will draw the melted solder into the joint by capillary action. Use the flame sparingly.

-

4Melt solder into the joint. Move the solder and flame to the side opposite the melted solder, continually feeding small amounts of solder and moving the torch until the solder has circled the fitting.

- The solder will seem to run toward the heat. The purpose is to allow the solder to completely fill the area between the fitting and the tubing by letting it run into the cracks. On larger fittings, concentrate the heat slightly ahead of the wetted solder to allow this to occur.

- Be careful not to overheat the copper. Keep the torch moving constantly to prevent blackening the copper. If the joint is overheated and blackened, you'll need to disassemble it and re-clean the pipe, otherwise you'll risk a leaky fitting.

-

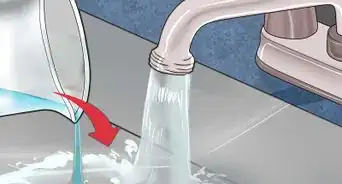

5Wipe excess liquid solder from the hot surfaces using a clean, dry cotton rag. Spray a mist of water on the area soldered to freeze the solder and prevent movement of the joint which would create a leak.

-

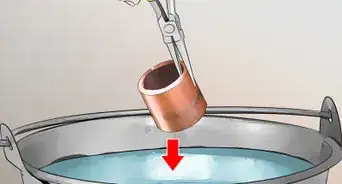

6Flush the piping thoroughly. Use fresh potable water to remove any excess flux, dirt, or loose solder beads inside the tubing after all soldered connections are completed. This will also help you check for leaks when the job is done.

Community Q&A

-

QuestionWhen there are multiple joints, which one should I solder first?

Community AnswerIf it's a mix of just elbows, T's, and couplings, then pick an end to start with and solder across everything to the other end. Moving the heat ahead of the path you're traveling will make the remaining joints easier and faster to solder. You'll also know what's been completed and what hasn't, in case you need to stop to answer the phone or get more flux, solder, or gas. However, if you have a valve with Teflon or rubber seals in the mix, then you want to start at the valve and work your way away from it and any surrounding heavier brass items (because you want to only heat a valve once while the valve's open to minimize or avoid damaging the valve seal(s)).

Community AnswerIf it's a mix of just elbows, T's, and couplings, then pick an end to start with and solder across everything to the other end. Moving the heat ahead of the path you're traveling will make the remaining joints easier and faster to solder. You'll also know what's been completed and what hasn't, in case you need to stop to answer the phone or get more flux, solder, or gas. However, if you have a valve with Teflon or rubber seals in the mix, then you want to start at the valve and work your way away from it and any surrounding heavier brass items (because you want to only heat a valve once while the valve's open to minimize or avoid damaging the valve seal(s)). -

QuestionHow long should I wait to run water through copper tubing after installing?

Community AnswerCopper can be used as soon as it cools; less than a minute is needed.

Community AnswerCopper can be used as soon as it cools; less than a minute is needed. -

QuestionHow can I solder thin strips of copper to copper tubing?

Community AnswerWith sanding (cleaning), fluxing, heating, and soldering in that order. Don't skip any of those steps on all items being attached and you'll be solid. The thin strips can be moderately clamped into place with real (metal) clamps after they're fluxed.

Community AnswerWith sanding (cleaning), fluxing, heating, and soldering in that order. Don't skip any of those steps on all items being attached and you'll be solid. The thin strips can be moderately clamped into place with real (metal) clamps after they're fluxed.

Warnings

- Be very careful of the hot solder dripping. It will blind you if it is flung into your eye. Wear safety glasses, protective gloves, and heavy clothing.⧼thumbs_response⧽

- Fire is an ever-present danger when using torches in confined areas. A fire extinguisher should be immediately available before lighting the torch. City ordinances usually require you to have a bucket of water beside you if you are soldering or welding.⧼thumbs_response⧽

Things You'll Need

- Copper tubing

- Sand cast or wrought fittings

- Solder

- Flux with flux brush

- Propane or acetylene torch

- Fire extinguisher

- Sandpaper

- Copper tubing reamer

- Tubing cutters

References

- ↑ http://www.familyhandyman.com/plumbing/how-to-solder-copper-pipe/view-all

- ↑ http://www.copper.org/applications/plumbing/cth/standard-tubes/cth_1stand_type.html

- ↑ http://www.copper.org/publications/pub_list/pdf/copper_tube_handbook.pdf

- ↑ https://www.copper.org/environment/water/e_p_lead.html

- ↑ https://hackaday.com/2017/02/23/what-the-flux-how-does-solder-work-anyway/

- ↑ https://www.familyhandyman.com/plumbing/how-to-solder-copper-pipe/?trkid=FBPAGE_TFH_20161227_Plumbing_Article

- ↑ https://www.copper.org/publications/pub_list/pdf/copper_tube_handbook.pdf

- ↑ https://www.familyhandyman.com/plumbing/how-to-solder-copper-pipe/?trkid=FBPAGE_TFH_20161227_Plumbing_Article

About This Article

To solder copper tubing, you'll need lead-free solid core solder, some solder flux, and a propane or acetylene air torch. Once you have your supplies, use some sandpaper to remove the copper oxide on the outside portion of the tubing that will be inserted into the fitting, as well as the inside of the fitting itself. Then, brush both surfaces with the solder flux and light your torch so you have a blue flame. Finally, melt solder into the joint and wipe away the excess using a clean, dry rag. To learn how to choose the best solder flux for the job, scroll down!