Beer fault

A beer fault or defect is a flavor deterioration caused by chemical changes to the organic compounds in beer, either due to improper production processes or storage. Various chemicals, including aldehydes (such as dactyl organic acids), lipids, sulfur compounds, and fermentation byproducts, can have a noticeable impact on flavour, even with slight changes. When the concentration of one or more of these chemicals exceeds the standard threshold, flavour characteristics may change, creating a flavour defect.

Beer faults and wine faults

Improper production or storage can also create wine flavour defects. External environmental factors often contribute to the chemical changes responsible for wine defects. Defects in wine flavour can result from inadequate winery sanitation, wine contamination, overuse of oak barrels, cork-related problems, spoilage, and fluctuations in temperature. Beer faults differ from wine faults due to different chemical processes in product creation. In the brewing beer, the concentration of inorganic chemical elements can be too high or too low due to improper production. The malting process of joining malt and hops in the brewing process may cause microbial deterioration, which leads to the loss of beer flavor.

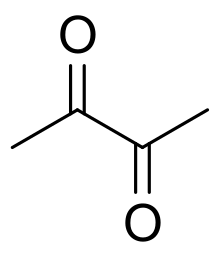

Diacetyl

Diacetyl is a chemical compound produced in yeast during fermentation and is reabsorbed in the process. Since the external ambient temperature during fermentation is lower than 26 °C (79 °F), diacetyl is absorbed insufficiently, resulting in a threshold of less than 0.04 mg/liter in beer, which gives the beer a mouthfeel similar to cream cheese.[1] This odor will persist over time. Since the decomposition of α-acetolactate produces a large amount of diacetyl, the method can avoid the beer flavor defects caused by diacetyl as follows: boil the container and clean it before the yeast fermentation. The wort should avoid contact with oxygen when the fermentation begins.[2] The temperature is raised by 2°-3° within 2 minutes of the end of the fermentation process, which allows the yeast to reabsorb faster so that the diacetyl content reaches 0.04 mg/L in the beer and does not cross the threshold.

Risotto taste

Beer can taste of glutinous rice if the diacetyl content exceeds its low taste threshold. For light-colored lagers, the diacetyl content should be below 0.1 mg/L, while for high-grade beer, it should be kept below 0.05 mg/L. The production of diacetyl can be reduced by several means:

- Increasing the α-amino nitrogen content of the wort. Generally, the α-amino nitrogen content of the 12P wort should be at least 180 ± 20 mg / L. Too low will lead to the synthesis and accumulation of α-acetolactic acid; too high will lead to excess nutrients in the yeast and excessively high alcohol content.[3]

- Reducing the proliferation of yeast, generally keeping the multiplication factor below three. Because the precursors of diacetyl and other yeast metabolic by-products are mostly produced during yeast breeding, we can reduce the yeast proliferation rate by adopting a series of measures such as low-temperature inoculation, inoculum, and low-temperature fermentation.

- Increasing the fermentation temperature in the late stage of the main fermentation.

Acids that cause beer fault

The fermentation of beer produces a large amount of acid. When it exceeds 170 mg/litre, it will create a strong sour taste similar to yogurt or pepper. Acids above the threshold are significant flavor defects in beer. A hygienic production environment, mashing the yeast strain for less than two hours, and keeping the fermentation temperature below 50 °C (122 °F) all help to reduce the amount of acid in beer. Brewing supplies and equipment should also use non-marking equipment because they can scratch the fermentation device; bacteria will remain inside the scratches. These bacteria can cause yeast to be contaminated during fermentation.[4]

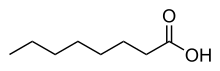

Octanoic

Octanoic acid (caprylic acid) is a fatty acid produced by the metabolism of yeast during fermentation. When the content of octanoic acid in the beer exceeds 4-6 mg/L, the beer will have a highly concentrated spicy taste. Beer storage in an environment below 26 °C (79 °F) will reduce this spicy taste. The use of fresh yeast and separation of the beer from the yeast cake promptly once fermentation is complete will also help keep the octanoic acid content beneath its taste threshold.[5]

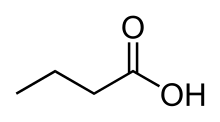

Butyric acid

Butyric acid is produced by bacteria, often from contamination of the adjunct syrups or from the production of the wort. When the content of butyric acid in beer exceeds 2-3 mg/litre, the beer tastes of rancid butter or vomit. Acidic sputum should be kept above 90 °F and avoid contact with oxygen. This method can avoid excessive butyric acid production. Additionally, the brewing environment must be kept clean.[6]

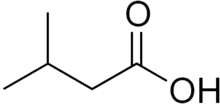

Isovaleric acid

Isovaleric acid is produced by the oxidation of hop resins, or by Brettanomyces yeasts present. The acid is present in the beer at a level of from 0.7 to 1 mg per litre. Above these levels the isovaleric acid produces a detectable cheesy or sweaty odor. Hops should be stored in an oxygen-free vacuum-tight container to prevent bacterial infection.[7]

Alcohols that cause beer fault

Thiol

Beers with thiols can produce odors similar to rotten vegetables or skunks. The threshold for mercaptans in beer is 1 microgram per liter. Mercaptan is often produced during fermentation with certain strains of yeast, the autolysis of yeasts, or by anaerobic bacterial infection.[8] One way to mitigate high levels of thiols is to remove the beer from the yeast four weeks after the start of fermentation. This helps prevent the beer from absorbing the mercaptan present in the dead yeast.

Lightstruck

Lightstruck tastes like a sulfur in beer. The desire to cause this taste is produced by the chemical reaction between riboflavin and hop alpha acid in beer by natural light or artificial light. This is also the reason why most beer bottles use green packaging. If the beer bottles are not green or not placed in the dark, the rate of aging will increase. In addition to being packaged in green bottles, storing beer in the dark is also a way to avoid lightstruck.[9]

Aldehyde

Acetaldehyde

Acetaldehyde causes the beer to taste like a green apple when the presence of acetaldehyde exceeds the threshold (5-15 mg/L). During the fermentation of beer, the ethanol present in the yeast can make contact with air if stored improperly, producing an oxidation reaction that turns some of the ethanol into acetaldehyde. To prevent the formation of acetaldehyde during the production process, fresh yeast should be fermented at a suitable ambient temperature, and the production environment should be hygienic. After the start of the fermentation, the fermentation is sealed with a material having a high sealing property. Before bottling, highly airtight materials transport beer to reduce oxygen entering the bottle.[10]

Phenolic

The presence threshold of phenolic in beer is 0.05-0.55 mg/L, and the beer with phenolic content exceeding the threshold has bitterness and smoky flavor. The washing water of the yeast is derived from tap water, and the chlorophenol in the tap water and the disinfectant containing the chlorine water are brewed to make the beer have phenolic. Therefore, an effective way to reduce phenolic is that tap water can be filtered before use. Non-chlorine disinfectants can also be selected for the type of disinfectant. The extraction of wort is at least 1.008 SG.

Hydrogen sulfide

Hydrogen sulfide produces a rotten egg flavor in beer. All yeast strains produce a certain amount of hydrogen sulfide during fermentation. The threshold of hydrogen sulfide in beer is 4 μg/L, and most of the hydrogen sulfide is doped in the released nitrogen dioxide, so when carrying out a large amount of fermentation, it takes a lot of time before bottling. Fermentation. Healthy yeast is used and fully oxidized wort, which increases the zinc content of the wort and reduces the hydrogen sulfide content.

Ferrous sulfate

Ferrous sulfate is caused by the contact of beer with metal materials during brewing, resulting in metal ion leaching. Excessive levels of ferrous sulfate can make beer taste like rusty iron and copper. If the content of ferrous sulfate in beer exceeds 1-1.5 mg/litre, drinkers will develop symptoms of dizziness. Drinkers may have poisoning symptoms if the beer contains a lot of ferrous sulfates. To prevent the formation of ferrous sulfate in producing beer, the water used for brewing is subjected to a metal ion reaction. Containers for fermented and finished beer should also be used in food-grade plastics. Beer should not come into contact with any corrodible container to reduce the number of metal ions in the beer.[8]

Oxygen

Oxygen can cause oxidation, which causes some aging reactions due to carbonyl compounds. The original auxiliary material is protected by CO2 or N2 when pulverized, and it is not easy to take too long before smashing. CO2 or N2 protects the equipment during the mashing process, and the bottom feed is used when smashing. The mixing frequency of sputum reduces, and as the stirring speed is reduced, pumps, seals, valves, etc., can not leak.[11] The maintenance can strengthen; when the wort boils, the pot door should close, and the boiling time should finish after the main leaven, and the product should be served as soon as possible. The post-fermenter tank uses CO2 to prepare the pressure, and the speed of the fermentation tank is controlled to be less than 1m/s.[8]

Dimethyl sulfide

Dimethyl sulfide exhibits a sour-sweet cream flavor when it exceeds 0.025 mg/L in beer. Dimethyl sulfide is derived from sulfur-based organic compounds produced during malt development.[12] Bacterial contamination occurs during the fermentation of yeast and bacterial contamination can also cause sulphur to produce dimethyl sulfide. If the beer uses a particular variety of malts, such as pulses malt, barley malt, and other sulfur-based organic compounds, the content of dimethyl sulfide is higher than ordinary ale, so the beer in the production process should reduce the use of such products. Too much water in the wort can also produce large amounts of sulfur-based organic compounds, so the malt should be stored in a dry place. Based on the volatility of dimethyl sulfide, the wort can be volatilized by boiling at a high temperature for 60 minutes to 90 minutes to liberate 90% of dimethyl sulfide.

Oxidation

Oxidised beer has the mouldy taste of old newspapers. Beer with 100% oxygen exposure has the fastest oxidation rate. Temperature is another cause of oxidation, as it produces a lot of oxygen in a high-temperature environment.[13] This oxygen also accelerates the price of beer oxidation. To avoid excessive beer exposure to oxygen, the headspace reserved for the beer placed in the bottle is less than one inch. If the beer is to be stored, the temperature inside the bowl should be below 50 degrees Fahrenheit.[14]

Detecting beer faults

Historically, inspectors had their methods of testing the quality of beer or checking for specific faults, such as the test that might have been done to check if there was too much sugar in it (that supposedly involved the inspector pouring a small amount onto his chair and sitting down to see if his clothing stuck to the seat.) Now, there are guides such as the Complete Beer Fault Guide, which explain what to look for and how to detect specific faults by taste, smell, and texture/mouth feel.[15]

See also

References

- White, Christopher. "Diacetyl Time Line" (PDF).

{{cite journal}}: Cite journal requires|journal=(help) - "The role of diacetyl in beer". Drayman's. 2016-06-12. Retrieved 2019-05-31.

- "Controlling Diacetyl". Brew Your Own. Retrieved 2019-05-17.

- "Temperature Factors - How to Brew". howtobrew.com. Retrieved 2019-05-31.

- Kabay, Nalan (2015), "Boron Removal From Geothermal Water Using Membrane Processes", Boron Separation Processes, Elsevier, pp. 267–283, doi:10.1016/b978-0-444-63454-2.00012-5, ISBN 9780444634542

- "Common Off-Flavors - How to Brew". howtobrew.com. Archived from the original on 2023-04-24. Retrieved 2019-05-31.

- "The Oxford Companion to Beer Definition of isovaleric acid". Craft Beer & Brewing. Retrieved 2019-05-31.

- "18 Common Off Flavors In Beer (And How They're Caused)". Kegerator.com. 2016-07-01. Retrieved 2019-05-31.

- "Beer bottles: The answer is not clear". Brews News. 2010-08-07. Retrieved 2019-05-31.

- "Oxygen's Role in the Fermentation of Beer | MoreBeer". www.morebeer.com. Retrieved 2019-05-31.

- "Oral Penicillins Can Cause Rapid Severe Anaphylaxis Too". InPharma. 164 (1): 4. November 1978. doi:10.1007/bf03310487. ISSN 0156-2703. S2CID 198224843.

- "Dimethyl Sulfides (DMS) in Home Brewed Beer | Home Brewing Beer Blog by BeerSmith™". beersmith.com. Retrieved 2019-05-31.

- "Continuous ethanol fermentation by beer yeast". Journal of Fermentation Technology. 65 (1): 116. January 1987. doi:10.1016/0385-6380(87)90078-1. ISSN 0385-6380.

- "Beer bottles: The answer is not clear". Brews News. 2010-08-07. Retrieved 2019-05-31.

- Barnes, Thomas. "The complete beer fault guide v. 1.4." (2011).