Gold mining

Gold mining is the extraction of gold by mining. World gold production was 3,612 tons in 2022.[1]

Historically, mining gold from alluvial deposits used manual separation processes, such as gold panning. The expansion of gold mining to ores that are not on the surface, has led to more complex extraction processes such as pit mining and gold cyanidation. In the 20th and 21st centuries, most volume of mining was done by large corporations; however, the value of gold has led to millions of small, artisanal miners in many parts of the Global South.

Like all mining, human rights and environmental issues are common in the gold mining industry, and can result in environmental conflict. In mines with less regulation, health and safety risks are much higher.

Over three quarters of all gold is used for jewelry.[2]

History

The exact date that humans first began to mine gold is unknown, but some of the oldest known gold artifacts were found in the Varna Necropolis in Bulgaria. The graves of the necropolis were built between 4700 and 4200 BC, indicating that gold mining could be at least 7000 years old.[3] A group of German and Georgian archaeologists claims the Sakdrisi site in southern Georgia, dating to the 3rd or 4th millennium BC, may be the world's oldest known gold mine.[4]

Evidence suggests that Nubia had sporadic access to gold nuggets during the Neolithic and Prehistoric Period. During the Bronze Age, sites in the Eastern Desert became a great source of gold-mining for nomadic Nubians, who used "two-hand-mallets" and "grinding ore extraction." By the Old Kingdom, the oval mallet was introduced for mining. By the Middle Kingdom, stone mortars to process ores and a new gold-washing technique were introduced. During the New Kingdom, Nubian mining expanded under Egyptian occupation with the invention of the grinding mill.[5]

Bronze Age gold objects were also plentiful, especially in Ireland and Spain, and there are several well known possible sources. Romans used hydraulic mining methods, such as hushing and ground sluicing on a large scale to extract gold from extensive alluvial (loose sediment) deposits, such as those at Las Medulas. Mining was under the control of the state but the mines may have been leased to civilian contractors some time later. The gold served as the primary medium of exchange within the empire, and was an important motive in the Roman invasion of Britain by Claudius in the first century AD, although there is only one known Roman gold mine at Dolaucothi in west Wales. Gold was a prime motivation for the campaign in Dacia when the Romans invaded Transylvania in what is now modern Romania in the second century AD. The legions were led by the emperor Trajan, and their exploits are shown on Trajan's Column in Rome and the several reproductions of the column elsewhere (such as the Victoria and Albert Museum in London).[6] Under the Eastern Roman Empire Emperor Justinian's rule, gold was mined in the Balkans, Anatolia, Armenia, Egypt, and Nubia.[7]

In the area of the Kolar Gold Fields in Bangarpet Taluk, Kolar District of Karnataka state, India, gold was first mined prior to the 2nd and 3rd century AD by digging small pits. (Golden objects found in Harappa and Mohenjo-daro have been traced to Kolar through the analysis of impurities – the impurities include 11% silver concentration, found only in KGF ore.) The Champion reef at the Kolar gold fields was mined to a depth of 50 metres (160 ft) during the Gupta period in the fifth century AD. During the Chola period in the 9th and 10th century AD, the scale of the operation grew. The metal continued to be mined by the eleventh century kings of South India, the Vijayanagara Empire from 1336 to 1560, and later by Tipu Sultan, the king of Mysore state and the British. It is estimated that the total gold production in Karnataka to date is 1000 tons.[8]

.TIF.jpg.webp)

The mining of the Hungarian deposit (present-day Slovakia) primarily around Kremnica was the largest of the Medieval period in Europe.[9]

During the 19th century, numerous gold rushes in remote regions around the globe caused large migrations of miners, such as the California Gold Rush of 1849, the Victorian Gold Rush, and the Klondike Gold Rush. The discovery of gold in the Witwatersrand led to the Second Boer War and ultimately the founding of South Africa. Gold-bearing reefs in the neighbouring Free State province were found shortly thereafter, driving significant development in the region with the establishment of the Free State goldfields.

The Carlin Trend of Nevada, U.S., was discovered in 1961. Official estimates indicate that total world gold production since the beginning of civilization has been around 6,352,216,000 troy ounces (197,576.0 t) and total gold production in Nevada is 1.1% of that, ranking Nevada as one of the Earth's primary gold producing regions.[10][11]

As of 2020, the world's largest gold producer was China with 368.3 tonnes of gold mined in that year. The second-largest producer of gold was Russia where 331.1 tonnes was mined in the same year, followed by Australia with 327.8 tonnes.[12]

Statistics

Despite its decreasing content in ores, gold production is increasing. This increase can be achieved through ever larger-scale industrial installations as well as innovations, especially in hydrometallurgy.

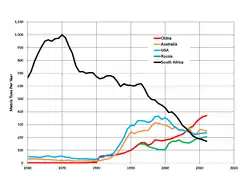

Trends in some gold-producing countries

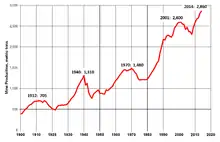

Trends in some gold-producing countries Annual world mined gold production, 1900–2014

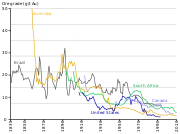

Annual world mined gold production, 1900–2014 Gold ore grade evolution

Gold ore grade evolution

Methods

Hard rock mining

Hard rock mining extracts gold encased in rock, rather than fragments in loose sediment, and produces most of the world's gold. Sometimes open-pit mining is used, such as at the Fort Knox Mine in central Alaska. Barrick Gold Corporation has one of the largest open-pit gold mines in North America located on its Goldstrike mine property in north eastern Nevada. Other gold mines use underground mining, where the ore is extracted through tunnels or shafts. South Africa has the world's deepest hard rock gold mine up to 3,900 metres (12,800 ft) underground. At such depths, the heat is unbearable for humans, and air conditioning is required for the safety of the workers. The first such mine to receive air conditioning was Robinson Deep, at that time the deepest mine in the world for any mineral.[13]

By-product gold mining

Gold is also produced by mining in which it is not the principal product. Large copper mines, such as the Bingham Canyon mine in Utah, often recover considerable amounts of gold and other metals along with copper. Some sand and gravel pits, such as those around Denver, Colorado, may recover small amounts of gold in their wash operations. The largest producing gold mine in the world, the Grasberg mine in Papua, Indonesia, is primarily a copper mine.[14]

A modest amount of precious metal is a by-product of sodium production.

Niche, recreational, or historical methods

.jpg.webp)

Gold panning, or simply panning, is a form of placer mining and traditional mining that extracts gold from a placer deposit using a pan. The process is one of the simplest ways to extract gold, and is popular with geology enthusiasts especially because of its low cost and relative simplicity.

The first recorded instances of placer mining are from ancient Rome, where gold and other precious metals were extracted from streams and mountainsides using sluices and panning[15] (ruina montium).

However, the productivity rate is comparatively smaller compared to other methods such as the rocker box or large extractors, such as those used at the Super Pit gold mine, in Kalgoorlie, Western Australia, which has led to panning being largely replaced in the commercial market.Placer mining

Placer mining is the technique by which gold that has accumulated in a placer deposit is extracted. Placer deposits are composed of relatively loose material that makes tunnelling difficult, and so most means of extracting it involve the use of water or dredging.

Sluicing

Using a sluice box to extract gold from placer deposits has long been a very common practice in prospecting and small-scale mining. A sluice box is essentially a man made channel with riffles set in the bottom. The riffles are designed to create dead zones in the current to allow gold to drop out of suspension. The box is placed in the stream to channel water flow. Gold-bearing material is placed at the top of the box. The material is carried by the current through the volt where gold and other dense material settles out behind the riffles. Less dense material flows out of the box as tailings.

Larger commercial placer mining operations employ screening plants, or trommels, to remove the larger alluvial materials such as boulders and gravel, before concentrating the remainder in a sluice box or jig plant. These operations typically include diesel powered, earth moving equipment, including excavators, bulldozers, wheel loaders, and rock trucks.

Dredging

Although this method has largely been replaced by modern methods, some dredging is done by small-scale miners using suction dredges. These are small machines that float on the water and are usually operated by one or two people. A suction dredge consists of a sluice box supported by pontoons, attached to a suction hose which is controlled by a miner working beneath the water.

State dredging permits in many of the United States gold dredging areas specify a seasonal time period and area closures to avoid conflicts between dredgers and the spawning time of fish populations. Some US states, such as Montana, require an extensive permitting procedure, including permits.

Some large suction dredges (100 horsepower (75 kW) & 250 mm (10 in)) are used in commercial production throughout the world. Small suction dredges are much more efficient at extracting smaller gold than the old bucket line. This has improved the chances of finding gold. Smaller dredges with 50-to-100-millimetre (2 to 4 in) suction tubes are used to sample areas behind boulders and along potential pay streaks, until "colour" (gold) appears.

Other larger scale dredging operations take place on exposed river gravel bars at seasonal low water. These operations typically use a land based excavator to feed a gravel screening plant and sluice box floating in a temporary pond. The pond is excavated in the gravel bar and filled from the natural water table. "Pay" gravel is excavated from the front face of the pond and processed through the floating plant, with the gold trapped in the onboard sluice box and tailings stacked behind the plant, steadily filling in the back of the pond as the operation moves forward. This type of gold mining is characterized by its low cost, as each rock is moved only once. It also has low environmental impact, as no stripping of vegetation or overburden is necessary, and all process water is fully recycled. Such operations are typical on New Zealand's South Island and in the Klondike region of Canada.

Rocker box

Also called a cradle, a rocker box uses riffles located in a high-walled box to trap gold in a similar manner to the sluice box. A rocker box uses less water than a sluice box and is well suited for areas where water is limited. A rocking motion provides the water movement needed for the gravity separation of gold in placer material.

Gold ore processing

Cyanide process

The dominant method for refining gold is a cyanide extraction method introduced in the late 1800s. Finely ground rock is treated with a solution of sodium cyanide. The extract is absorbed onto carbon and then removed from the carbon with a solution of caustic soda and cyanide. Gold cyanide is then converted to relatively pure gold through gold parting.

There are many environmental hazards associated with this extraction method, largely due to the high toxicity of the cyanide compounds. For example, in 2000, the Baia Mare cyanide spill in northern Romania released approximately 100,000 cubic metres (3,500,000 cu ft) of waste water contaminated with heavy metal sludge and up to 120 long tons (122 t) of cyanide into the Tisza River.[16]

Mercury process

Historically, mercury was used extensively in placer gold mining in order to form mercury-gold amalgam with smaller gold particles, and thereby increase the gold recovery rates. The gold is concentrated by boiling away the mercury from the amalgam. This is effective in extracting very small gold particles, but the process is hazardous due to the toxicity of mercury vapour.[17] Large-scale use of mercury stopped in the 1960s. However, mercury is still used in artisanal and small-scale gold mining (ASGM).[18]

Business

Small operations

While most gold is produced by major corporations, there are an estimated 10 to 15 million small-scale artisanal gold miners worldwide. 4.5 million of them are women, and an estimated 600,000 children work in illegal artisanal gold mines. Artisanal miners use rudimentary methods to extract and process gold. Many of these people are mining to escape extreme poverty, unemployment and landlessness.

In Ghana, galamsey miners are estimated to number 20,000 to 50,000.[19] In neighboring francophone countries, such workers are called orpailleurs, and in Brazil, Venezuela, Suriname and French Guiana: garimpeiros.[20][21][22]

Miners risk government persecution, mine shaft collapses, and toxic poisoning from unsafe chemicals used in processing, such as mercury. For example, in Ghana during 2009, the Dompoase mine collapse killed 18 workers. It was the worst mining disaster in Ghanaian history.[19]

Children in these mines suffer extremely harsh working conditions and various hazards such as collapsing tunnels, explosions, and chemical exposure. Children may be especially vulnerable to these hazards, and many suffer from serious respiratory conditions, hearing and sight problems, and other disorders.[23]

Large companies

Gold mining by large multi-national corporations, produces about 80% of the gold supply. Most gold is mined in developing nations. Large mining companies play a key role in globalisation of the economy by linking rich and poor companies.[2] Newmont and Barrick Gold are the largest gold mining companies in the world, but there are many smaller corporations in the industry.[24]

Local communities are frequently vulnerable to environmental degradation caused by large mining companies and may lack government protection or industry regulation.[2] For example, thousands of people around Lega Dembi mine are exposed to mercury, arsenic, and other toxins resulting in widespread health problems and birth defects.[25] Vulnerable communities may also lose their land to the mine.[26] These issues can result in environmental conflict.[24] Some large companies have attempted to build local legitimacy through corporate responsibility initiatives and local development.[2][26]

Adverse effects and responses

| Part of a series on |

| Pollution |

|---|

|

Gold mining can significantly alter the natural environment. For example, gold mining activities in tropical forests are increasingly causing deforestation along rivers and in remote areas rich in biodiversity.[27][28] Other gold mining impacts, particularly in aquatic systems with residual cyanide or mercury (used in the recovery of gold from ore), can be highly toxic to people and wildlife even at relatively low concentrations.[29]

Gold mining produces more waste than mining of other minerals, because it can be mined at a lower grade. Tailings can contain lead, mercury, cadmium, and arsenic. These toxins can pose health risks for local communities.[2]

Arsenic is typically found in gold-containing ores, and gold processing may contaminate groundwater or the atmosphere. This pollution may persist for decades.[30]

Human Rights Watch produced a report in 2015 that outlined some of challenges faced globally. The report notes that

Thousands of children in the Philippines risk their lives every day mining gold. Children work in unstable 25-meter-deep pits that could collapse at any moment. They mine gold underwater, along the shore, or in rivers, with oxygen tubes in their mouths. They also process gold with mercury, a toxic metal, risking irreversible health damage from mercury poisoning.[31]

Fairtrade and Fairmined dual certification for gold was launched across the United Kingdom on 14 February 2011,[32] a joint scheme between The Fairtrade Foundation and The Association for Responsible Mining. The Fairmined mark ensures that the gold has been extracted in a fair and responsible manner.

A UN investigation reported human rights abuses such as sexual exploitation of women and children, mercury poisoning and child labor affecting communities where illegal gold production occurs. The reports said global buyers such as Switzerland, through which roughly two-thirds of global trade transits, need to ensure that human rights are respected throughout supply chains.[33]

The discovery of significant gold deposits in a region often sees a flood of resources and development, which lasts as long as the mines are economic. When goldfields begin to decline in production, local economies find themselves destabilised and overly reliant upon an industry that will inevitably abandon the region when gold deposits are sufficiently depleted.[34]

See also

Gold mining by country:

- Witwatersrand around Johannesburg, South Africa

- Witwatersrand Basin in South Africa

- Deepest mines on earth are the gold mines in South Africa

- Gold mining in Brazil

- Gold mining in Africa

- Gold mining in Australia

- Gold mining in the United States

- City of Gold in Canada

- Gold mining in China

- Gold mining in India

- Gold mining in Guyana

- Gold mining in Pakistan:

- Welsh gold

- Sukari, Egypt

- Gold mining in Switzerland

- Gold mine Gondo[35]

Gold rushes:

- United States:

- Georgia Gold Rush (beginning 1828)

- California Gold Rush (1848–1855)

- Pike's Peak Gold Rush (1858–1860)

- Holcomb Valley gold rush (1860s)

- British Commonwealth:

- Australian gold rushes (1850s)

- Victorian Gold Rush (1851–1860s)

- Fraser Canyon Gold Rush (late 1850s), Canada

- Witwatersrand Gold Rush (1880s), South Africa

- Klondike Gold Rush (1896–1899), Canada

- Central Otago Gold Rush (1860s), New Zealand

- Australian gold rushes (1850s)

References

- "Supply". World Gold Council. Archived from the original on 13 April 2023. Retrieved 13 April 2023.

- Gifford, Blair; Kestler, Andrew; Anand, Sharmila (1 July 2010). "Building local legitimacy into corporate social responsibility: Gold mining firms in developing nations". Journal of World Business. 45 (3): 304–311. doi:10.1016/j.jwb.2009.09.007. ISSN 1090-9516.

- Ivanov, Ivan Simeonov; Avramova, Mai︠a︡ (2000). Varna Necropolis: The Dawn of European Civilization. Treasures of Bulgaria 1. Sofia: Agatʹo Publ.

- Hauptmann, Andreas; Klein, Sabine (2009). "Bronze Age gold in Southern Georgia". ArcheoSciences. 33 (33): 75–82. doi:10.4000/archeosciences.2037. Archived from the original on 25 May 2014. Retrieved 24 May 2014.

- Klemm, Rosemarie; Klemm, Dietrich (13 December 2012). Gold and Gold Mining in Ancient Egypt and Nubia: Geoarchaeology of the Ancient Gold Mining Sites in the Egyptian and Sudanese Eastern Deserts. Springer Science & Business Media. pp. 3–9. ISBN 978-3-642-22508-6.

{{cite book}}: CS1 maint: date and year (link) - Dan Oancea, A Tale of Gold Archived 3 March 2016 at the Wayback Machine

- Dan Oancea, Justinian's Gold Mines Archived 2 March 2009 at the Wayback Machine

- "The Golden Heritage of Karnataka". ernet.in. Archived from the original on 18 November 2019. Retrieved 3 April 2015.

- M M Postan; E Miller (1987) [1967], The Cambridge Economic History of Europe: Trade and industry in the Middle Ages, Cambridge University Press, ISBN 0521087090

- "How Much Gold Has Been Mined?". www.gold.org. Archived from the original on 29 September 2018. Retrieved 26 November 2021.

- "Dan Oancea – Carlin: Where the Train Stops and the Gold Rush Begins" (PDF). Archived (PDF) from the original on 4 March 2016. Retrieved 5 May 2013.

- "Gold Production by Country – Gold Production – Goldhub". www.gold.org. Archived from the original on 26 June 2019. Retrieved 26 November 2021.

- "Deepest Mine To Be Air Conditioned" Popular Science, October 1934

- Calderon, Justin (27 May 2013). "World's largest gold mine reopens". Inside Investor. Archived from the original on 19 October 2013. Retrieved 27 May 2013.

- Lynn Cohen Duncan (9 December 1999), Roman Deep-vein Mining, retrieved 14 December 2009

- Cyanide spill at Baia Mare Romania: UNEP/OCHA Assessment Mission (PDF), archived (PDF) from the original on 25 September 2012, retrieved 7 July 2011

- Chemicals and Waste Branch UNEP: ASGM: Eliminating the worst practices Archived 5 December 2017 at the Wayback Machine, YouTube, September 2017.

- Feijoo, M. D. A., Walker, T. R. (2018). Correspondence to the Editor Re: Artisanal and small-scale gold mining impacts in Madre de Dios, Peru: Management and mitigation strategies. Environment International, 111, 133-134. doi:10.1016/j.envint.2017.11.029

- "Women die in Ghana mine collapse". BBC News. 12 November 2009. Archived from the original on 14 November 2009. Retrieved 12 November 2009.

- "Lourenço já contabiliza 20 garimpeiros mortos. Condições de trabalho são precárias". Seles Nafes (in Portuguese). Archived from the original on 14 August 2021. Retrieved 31 March 2021.

- "Brazilianen in Suriname". Waterkant (in Dutch). Archived from the original on 25 March 2023. Retrieved 31 March 2021.

- "En Guyane, la lutte sans fin contre les « garimpeiros », ces orpailleurs clandestins". Le Monde (in French). Archived from the original on 29 March 2021. Retrieved 31 March 2021.

- International Journal of Engineering and Information Systems (IJEAIS) ISSN: 2643-640X Vol. 4 Issue 10, October - 2020, Pages: 12-16 www.ijeais.org/ijeais 12 Small-Scale Gold Mining Progress in Prospects in Improving Countries Umirzoqov Azamat Abdurashidovich, Bekmuratov Ajiniyaz Omirbek ogli http://ijeais.org/wp-content/uploads/2020/10/IJEAIS201005.pdf Archived 13 April 2023 at the Wayback Machine

- Dougherty, Michael L. (2013). "The Global Gold Mining Industry: Materiality, Rent-Seeking, Junior Firms and Canadian Corporate Citizenship". Competition & Change. 17 (4): 339–354. doi:10.1179/1024529413Z.00000000042. ISSN 1024-5294. S2CID 153829134. Archived from the original on 16 April 2023. Retrieved 13 April 2023.

- Boyd, David R (2022). Sacrifice zones 50 of the Most Polluted Places on Earth (PDF). Special Rapporteur on Human Rights and the Environment. Archived (PDF) from the original on 6 June 2023. Retrieved 13 April 2023.

- Yankson, Paul W. K. (1 May 2010). "Gold mining and corporate social responsibility in the Wassa West district, Ghana". Development in Practice. 20 (3): 354–366. doi:10.1080/09614521003709965. ISSN 0961-4524. S2CID 153570328.

- Asner, G. P., Llactayo, W., Tupayachi, R., and E. R. Luna (2015). "Elevated rates of gold mining in the Amazon revealed through high-resolution monitoring". Proceedings of the National Academy of Sciences of the United States of America. 110 (46): 18454–18459. doi:10.1073/pnas.1318271110. PMC 3832012. PMID 24167281.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - Alvarez, N.L; T. M. Aide (2015). "Global demand for gold is another threat for tropical forests". Environmental Research Letters. 10 (1): 014006. Bibcode:2015ERL....10a4006A. doi:10.1088/1748-9326/10/1/014006.

- Environmental and Health Effects Archived 30 November 2012 at the Wayback Machine. Cyanidecode.org. Retrieved on 26 October 2010.

- Eisler, Ronald (2004), "Arsenic Hazards to Humans, Plants, and Animals from Gold Mining", Reviews of Environmental Contamination and Toxicology, vol. 180, New York, NY: Springer, pp. 133–165, doi:10.1007/0-387-21729-0_3, ISBN 978-0-387-21729-1, PMID 14561078, retrieved 12 June 2023

- "What … if Something Went Wrong? Hazardous Child Labor in Small-Scale Gold Mining in the Philippines". Human Rights Watch. 29 September 2015. Archived from the original on 18 October 2016. Retrieved 17 October 2016.

- Kate Carter (14 February 2011). "Fairtrade hallmark sets the gold standard". The Guardian. Archived from the original on 12 March 2016. Retrieved 20 December 2012.

- "Gold sourcing and Switzerland in focus at the Human Rights Council". Swissinfo. 26 September 2022. Archived from the original on 26 September 2022. Retrieved 26 September 2022.

- Enterprise., Centre for Development and (2005). Growth and development in South Africa's heartland : silence, exit, and voice in the Free State : abridged. Centre for Development and Enterprise. OCLC 68913299.

- See German Wikipedia > Goldmine Gondo

Further reading

- Ali, Saleem H. (2006), "Gold Mining and the Golden Rule: A Challenge for Developed and Developing Countries", Journal of Cleaner Production, 14 (3–4): 455–462, doi:10.1016/j.jclepro.2004.05.009

- Gudde, Erwin G. California Gold Camps: A Geographical and Historical Dictionary of Camps, Towns, and Localities Where Gold Was Found and Mined; Wayside Stations and Trading Centers (Univ of California Press, 1975).

- Hess, Frank L., C. W. Hayes, and W. Lindgren. "Gold mining in the Randsburg quadrangle, California." Contributions to Economic Geology: US Geological Survey Bulletin (1910): 23–47. Online

- Kelley, Robert L. "Forgotten Giant: The Hydraulic Gold Mining Industry In California." Pacific Historical Review 23.4 (1954): 343–356. Online

- Paul, Rodman Wilson, ed. The California Gold Discovery: Sources, Documents, Accounts, and Memoirs Relating to the Discovery of Gold at Sutter's Mill (Talisman Press, 1967), Primary sources.

- Rohe, Randall E. "Hydraulicking in the American West: The development and diffusion of a mining technique." Montana: The Magazine of Western History (1985) 35#2 to: 18–35. Online

- Rohe, Randall. "Origins & Diffusion of Traditional Placer Mining in the West" Material Culture 18#3 (1986), pp. 127–166 Online

- White F. Miner with a Heart of Gold: biography of a mineral science and engineering educator. Friesen Press, Victoria. 2020. ISBN 978-1-5255-7765-9 (Hardcover), 978-1-5255-7766-6 (Paperback), 978-1-5255-7767-3 (eBook).

.jpg.webp)