This article was co-authored by wikiHow Staff. Our trained team of editors and researchers validate articles for accuracy and comprehensiveness. wikiHow's Content Management Team carefully monitors the work from our editorial staff to ensure that each article is backed by trusted research and meets our high quality standards.

There are 9 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 17,974 times.

Learn more...

The clutch plate is the mechanical device that allows you to shift gears in a manual transmission, and over time, it can wear down. If you notice your car is struggling to change gears, your vehicle vibrates, or it doesn’t change gears at all when you shift, it may be time to replace your clutch plate. If you’re an experienced mechanic, you may be able to handle the job yourself, but you may want to take your vehicle to an auto repair shop to make sure it’s done right. To help you out, we’ve put answered a few common questions about what it takes to fit a new clutch plate into place.

Steps

Is it hard to replace a clutch?

-

An experienced home mechanic can handle the task with the right tools. If you don’t have any experience working on cars, save the job for a licensed mechanic who can make sure it’s done right and safely. You’ll need to be able to raise the vehicle and know how to drop a transmission. You’ll also need special tools like a torque wrench and a flywheel turner.[1] X Research source

- Keep in mind if the job isn’t done right, you could seriously damage your transmission. If you’re in doubt, have a licensed mechanic handle it.

How do you choose a replacement clutch plate?

-

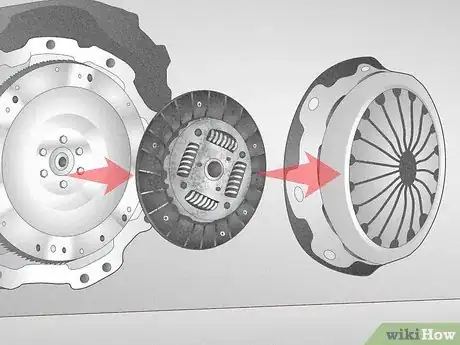

Choose a clutch kit so you have matching parts. Clutch plates can be made out of organic, ceramic, and metallic materials. Organic materials switch your gears smoother but wear down faster than metallic materials, and ceramic clutch plates are an even mix of both. Choose a material that suits your needs and go with a full clutch kit that also includes a pressure plate that matches your clutch so everything lines up consistently.[2] X Research source

- You can also customize your pressure plates, but it’s important that they’re designed to fit over your clutch plate.

- For a simpler option, choose a clutch plate that’s the same as the one you’re replacing.

How do you access the clutch plate?

-

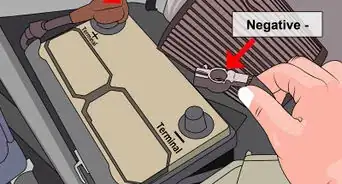

Lift the vehicle, remove the driveshaft, and support the transmission. Use a floor jack to lift your vehicle and then place jack stands beneath the axles to keep the vehicle safely raised. Drain the transmission oil and disconnect the driveshaft. Remove the electrical connections and bolts holding the transmission and then use a transmission jack to move it out of the way to access the clutch plate.[3] X Research source

- It’s extremely important that you support the raised vehicle with the proper jack stands so it doesn’t fall off.

How do you remove the old clutch plate?

-

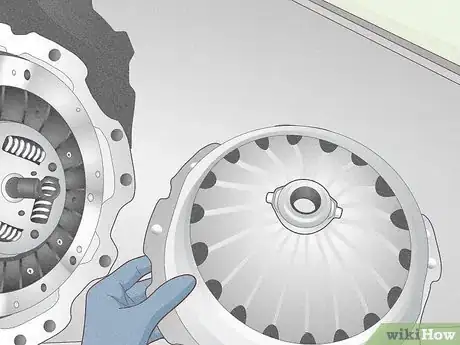

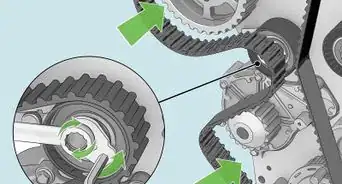

Remove the pressure plate and pull off the old clutch plate. Once you’ve got the transmission out of the way, you’ll see the pressure plate. Use a wrench or drill to remove the bolts holding the pressure plate in place and remove it. Then, slide the clutch plate off of the pilot bearing shaft.[4] X Research source

How do you connect a clutch plate to the pilot shaft?

-

Use a guide tool to fit the clutch plate onto the pilot bearing shaft. A clutch guide tool, also known as a clutch alignment tool, is a cylindrically shaped metal tool with slots that fit into the center of your clutch and a ring on 1 end. Insert the guide tool into the center of your clutch, then push the thinner end of the tool into your drive shaft as far as it will go.[5] X Research source

- The alignment tool is designed to hold your clutch at the perfect distance from the transmission.

- You can find alignment tools at your local auto supply shop.

Which way does a clutch plate go in?

-

Always place the flat side of the clutch plate against the motor. Take a look at your clutch plate. You’ll see springs that stick out more on 1 side, leaving the other side more or less flat. The flat side faces against the transmission in the bell housing.[6] X Research source

Can you replace just the clutch plate?

-

Replace the thrust bearing, pressure plate, and slave cylinder. Your thrust bearing helps your clutch spin freely when you change gears and takes a lot of abuse over time. Your pressure plate also has to deal with a lot of tension and can start to bend or crack. The slave cylinder helps your clutch plate move when you press on the clutch pedal and can eventually leak or seize. Since you’ll already be accessing the inner components when you change your clutch plate, it’s a great time to also replace these parts.[7] X Research source

- Additionally, many clutch kits come with matching clutch plates and pressure plates. Replace both at the same time so they line up perfectly.

How do you connect the pressure plate to the clutch plate?

-

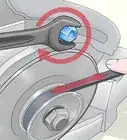

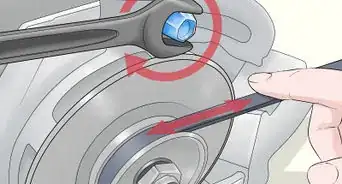

Install the pressure plate and torque the bolts in a criss-cross pattern. Cover the clutch with the pressure plate and insert the holding screws into each of the slots by hand. Check your the owner’s manual to find the torque specs for your specific vehicle’s pressure plate and adjust your torque wrench to match. Torque 1 bolt, then torque the bolt directly across from it. Continue torquing in a criss-cross or star-shaped pattern until all of the bolts are tightened.[8] X Research source

- For example, if your owner’s manual says your pressure plate needs to be torqued down to 24 foot-pounds (3.32 kilogram-meters), then set your torque wrench to match it.

- You can find torque wrenches at hardware stores and auto supply shops.

How do you break in a new clutch?

-

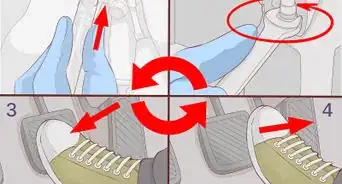

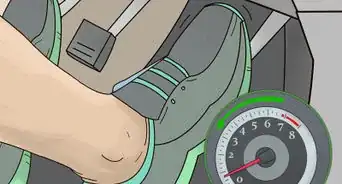

Drive for at least 500 miles (800 km) to properly break in your clutch. Breaking in a new clutch is similar to breaking in a new engine—you drive around and give it time. Spend the first 500 miles (800 km) or so driving normally. Don’t rev up the engine or stress your clutch too much by driving really fast or downshifting aggressively. Once the clutch is broken in, you can start pushing your vehicle a little harder out on the road.[9] X Research source

How much does a clutch install cost?

-

The average cost is between $1,200 to $1,400 USD. The actual parts you’ll need usually cost between $700-$750 USD. The cost of labor generally runs from about $500 to $650 depending on how long the job takes. The advantage of having your clutch professionally installed is you can rest easy knowing that it was done right.[10] X Research source

Warnings

- Installing a clutch improperly can lead to serious transmission damage. If you’re unsure, let a licensed mechanic handle the job.⧼thumbs_response⧽

You Might Also Like

How to Choose The Right Torque Converter: Stall Speed, Brand and Size Guide

How to Choose The Right Torque Converter: Stall Speed, Brand and Size Guide

References

- ↑ https://www.autoweek.com/car-life/diy/a1715056/diy-tips-replacing-your-clutch-isnt-hard/

- ↑ https://www.stylemotivation.com/what-is-a-clutch-kits-torque-rating-how-do-you-choose/

- ↑ https://axleandchassis.com/best-clutch-brands/

- ↑ https://www.autoweek.com/car-life/diy/a1715056/diy-tips-replacing-your-clutch-isnt-hard/

- ↑ https://youtu.be/QyONyvYHAX0?t=34

- ↑ https://youtu.be/QyONyvYHAX0?t=24

- ↑ https://www.autoguru.com.au/car-advice/articles/five-parts-you-should-change-during-clutch-replacement

- ↑ https://youtu.be/QcWELyTbdP4?t=1382

- ↑ https://youtu.be/zNJzvc2MN2Q?t=322

About This Article