X

This article was co-authored by Matthew Rava. Matthew Rava is an Auto Repair Expert and the Co-founder & Head of Marketing of Brakes to You. He specializes in auto repairs that concern brakes. Matthew earned a BS from West Chester University of Pennsylvania.

This article has been viewed 98,255 times.

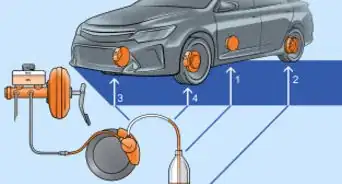

Flaring brake lines ensures a leak-proof connection without extra materials or sealants. If the brake lines aren't properly flared, you can lose fluid that will cause your brakes to fail. This article will explain how to flare your brake lines using single and double flares.

Steps

-

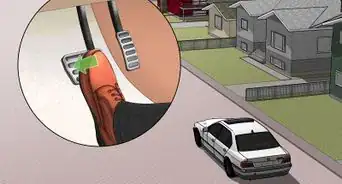

1Measure the length of brake line needed with measuring tape.

-

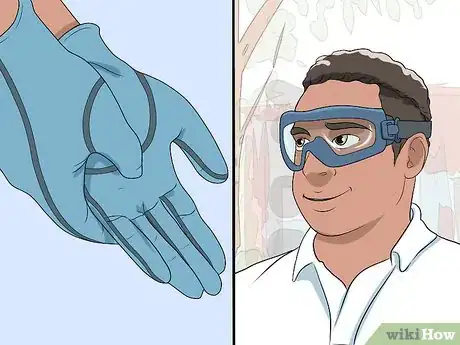

2Don hand and eye protection.Advertisement

-

3

-

4Use a flaring tool or a double flare tool to form the tubing's flare.[3]

- The instructions for both types of single flare tools are given below.

-

5Put the cone of the tool over the end of the tubing.

- Lower the cone down until it is centered over the tube's end.

-

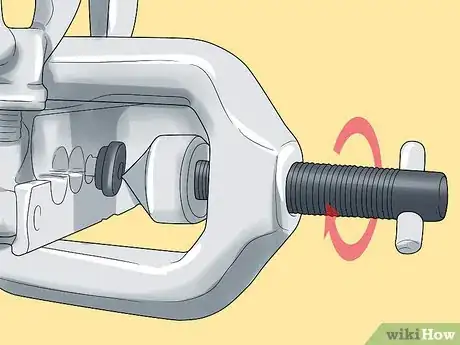

6Turn the advance screw to move the cone until the part of the tube being flared is firmly against the countersunk recess of the bar.

-

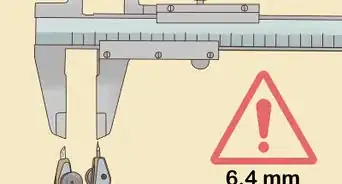

7Inspect the new flare for cracks, splits, or other imperfections. If the line is damaged at all, replace it with a new one.

Advertisement

Method 1

Method 1 of 2:

Generating Tool

-

1Place the cone over the end of the tubing and move it down until the cone is centered.

- On a generating flare tool, the flare is formed in the air instead of in the recessed part of the bar.

-

2Turn the advance screw several revolutions. Check the manual for the number of revolutions needed for the flare size you need.

-

3Check the new flare for any imperfections such as splits. If you end up with any damage, even a hairline crack, toss out the brake line and try again with a new one.

Advertisement

Method 2

Method 2 of 2:

Double Flaring Tool (New Standard)

-

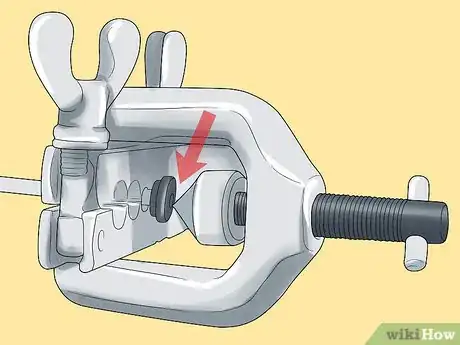

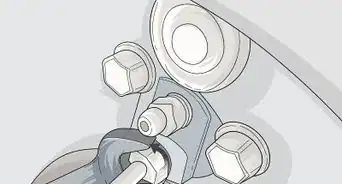

1Clamp your tubing into the flaring bar.[4]

- Ensure the depth is equal to the edge of your tubing size insert.

-

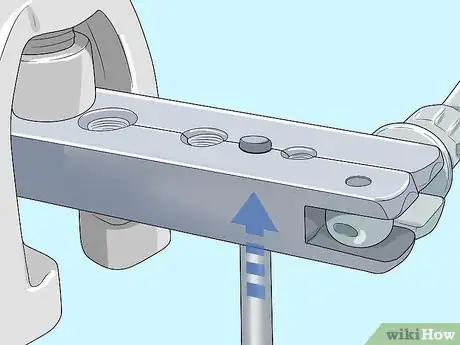

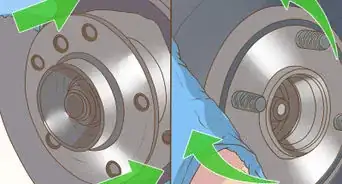

2Install the yoke and use it to advance the cone into the tube until a bell shape forms.[5]

- Remove the insert and finish advancing the cone into the bell.

- The bell shape of the tube forms the double thickness flare.

Advertisement

Community Q&A

-

QuestionCan I use a single in an application where a double flare was used?

Uglymug18Community AnswerNo. Double flare is used in high pressure ABS applications for a reason. A single flare is more likely to spit under high pressure, causing break failure.

Uglymug18Community AnswerNo. Double flare is used in high pressure ABS applications for a reason. A single flare is more likely to spit under high pressure, causing break failure.

Advertisement

Warnings

- Consult your tool's user guide for specific instructions. Tools' instructions can vary from manufacturer to manufacturer.⧼thumbs_response⧽

Advertisement

Things You'll Need

- Gloves and eye protection

- Measuring tape

- Brake tubing

- Tube cutters or hacksaw

- Single flare tool

- Double flare tool

References

- ↑ https://www.youtube.com/watch?v=IpT3jEnmmRs

- ↑ https://www.hotrodhotline.com/md/html/flaring_brake_line_3.php

- ↑ https://www.youtube.com/watch?v=IpT3jEnmmRs

- ↑ https://robrobinette.com/flare_brake_line.htm

- ↑ https://robrobinette.com/flare_brake_line.htm

- http://www.hotrodhotline.com/md/html/flaring_brake_line_3.php

About This Article

Advertisement