This article was co-authored by wikiHow staff writer, Eric McClure. Eric McClure is an editing fellow at wikiHow where he has been editing, researching, and creating content since 2019. A former educator and poet, his work has appeared in Carcinogenic Poetry, Shot Glass Journal, Prairie Margins, and The Rusty Nail. His digital chapbook, The Internet, was also published in TL;DR Magazine. He was the winner of the Paul Carroll award for outstanding achievement in creative writing in 2014, and he was a featured reader at the Poetry Foundation’s Open Door Reading Series in 2015. Eric holds a BA in English from the University of Illinois at Chicago, and an MEd in secondary education from DePaul University.

There are 7 references cited in this article, which can be found at the bottom of the page.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 95% of readers who voted found the article helpful, earning it our reader-approved status.

This article has been viewed 185,602 times.

Learn more...

Knowing how to braze aluminum can be a useful skill for anyone who is faced with a variety of at-home repairs. Brazing aluminum is a quick and inexpensive option for repairing leaks, cracks, or holes in aluminum and is often found in air-conditioning repairs. When compared to welding equipment, aluminum brazing equipment is inexpensive, portable, and does not require high amounts of voltage.

Things You Should Know

- Put on non-flammable gear and clear all dirt, oil, and grease from the area, then clamp the piece to be brazed and use a brush to apply an all-purpose flux.

- Heat the repaired area with a propane or acetylene torch, and apply the filler metal with a brazing rod.

- Remove the flux with hot water and polish the area with emery cloth once cooled; finish by applying a rust-resistant coating.

Steps

-

1Wear non-flammable clothing, gloves, and safety goggles before you begin the brazing process.

-

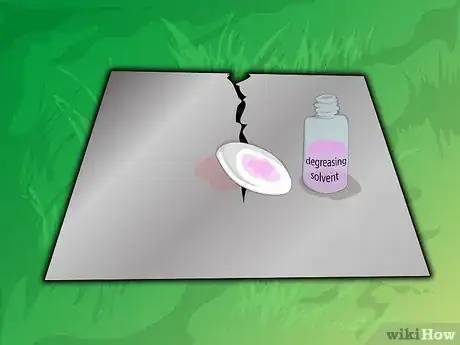

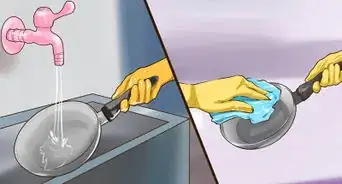

2Clean all dirt, oil, paint, or other residue from the area to be repaired by aluminum brazing. Use a degreasing solvent to get rid of oil and grease. Depending on the size of the repaired area, you may need to sandblast the area or use an emery cloth, grinding wheel, or file.Advertisement

-

3Clamp or support the piece to be brazed.

-

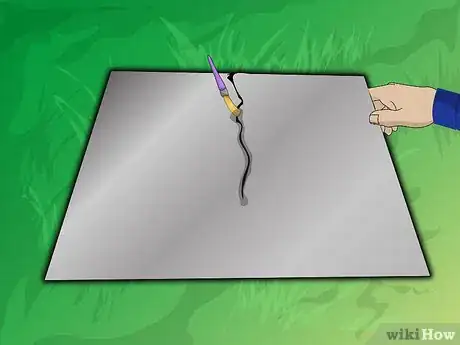

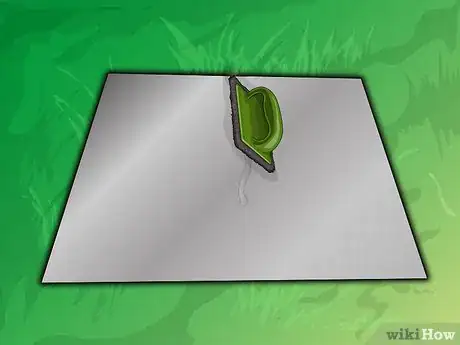

4Use a brush to apply the flux appropriate to the temperatures and the metal. An all-purpose flux covers a wide range of temperatures and is beneficial to have on hand for general purpose brazing. Add flux by dipping the filler rod into the flux. You may also use flux-coated rods to eliminate this step. The flux-coated rods apply the flux during the aluminum brazing process.

-

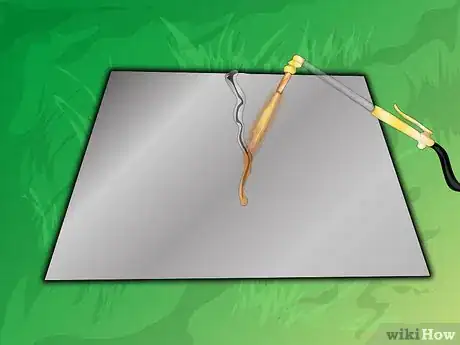

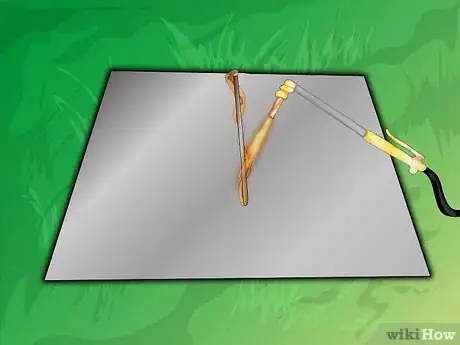

5Heat the repaired area with a propane or acetylene torch until the aluminum shows an orange bloom.[1] This happens when the metal gets very hot. Once you apply a flux, it should change colors or turn clear throughout.

-

6Apply the filler metal by running a brazing rod along the crack or the joint.[2] The heat of the metal will melt the filler into the area needing the repair. Move the flame of the torch on and off as needed to melt the rod.

-

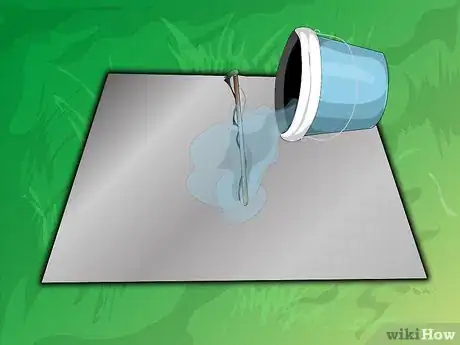

7Remove the flux after the filler material has solidified by dipping the part or pouring hot water on the repair.[3] The flux will flake off. If it does not come off, use a wire brush to gently scrub the brazed area while wet or still in the hot water.

-

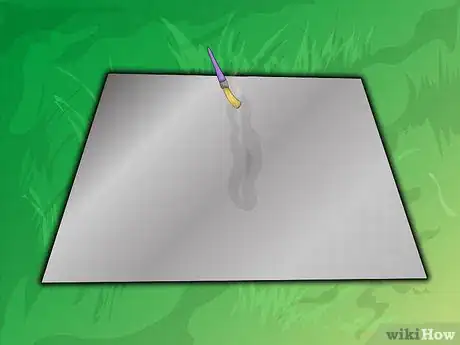

8Polish the area with an emery cloth after the metal has cooled completely.

-

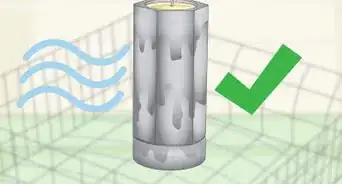

9Coat the area with a rust-resistant coating if you are not immediately finished with the area.[4]

Community Q&A

Did you know you can get answers researched by wikiHow Staff?

Unlock staff-researched answers by supporting wikiHow

-

QuestionCan I use acetylene to braze aluminum refrigeration pipes without flux using aluminum rods?

wikiHow Staff EditorThis answer was written by one of our trained team of researchers who validated it for accuracy and comprehensiveness.

wikiHow Staff EditorThis answer was written by one of our trained team of researchers who validated it for accuracy and comprehensiveness.

Staff Answer wikiHow Staff EditorStaff AnswerFor refrigeration pipes, it's best to fit another pipe with a larger diameter between the 2 pieces of copper to create a sleeve. You do need to use flux with copper pipes. Apply the flux along the joint where the larger pipe meets the 2 thinner pipes, and use a silver welding or brazing rod to seal the 2 joints.

wikiHow Staff EditorStaff AnswerFor refrigeration pipes, it's best to fit another pipe with a larger diameter between the 2 pieces of copper to create a sleeve. You do need to use flux with copper pipes. Apply the flux along the joint where the larger pipe meets the 2 thinner pipes, and use a silver welding or brazing rod to seal the 2 joints. -

QuestionCan you braze anodized aluminum?

wikiHow Staff EditorThis answer was written by one of our trained team of researchers who validated it for accuracy and comprehensiveness.

wikiHow Staff EditorThis answer was written by one of our trained team of researchers who validated it for accuracy and comprehensiveness.

Staff Answer wikiHow Staff EditorStaff AnswerYes, but you need a really strong brazing rod that will heat through the anodized layer. Anodized aluminum is essentially aluminum with another layer of metal on it, so the rod has to be strong enough to heat through the anodized layer and reach the aluminum. It's usually safer to weld anodized aluminum at a higher temperature to ensure that you penetrate the anodized layer.

wikiHow Staff EditorStaff AnswerYes, but you need a really strong brazing rod that will heat through the anodized layer. Anodized aluminum is essentially aluminum with another layer of metal on it, so the rod has to be strong enough to heat through the anodized layer and reach the aluminum. It's usually safer to weld anodized aluminum at a higher temperature to ensure that you penetrate the anodized layer. -

QuestionIs a high silver content in the rods better or worse for braising aluminum?

Community AnswerWorse, as the temp required is too high for the aluminum. Use the correct rods for the job.

Community AnswerWorse, as the temp required is too high for the aluminum. Use the correct rods for the job.

Warnings

- Flux becomes difficult to remove if the metal was overheated or if too little was applied.⧼thumbs_response⧽

- Corrosion, must be use Fluoride Flux not Chloride Flux⧼thumbs_response⧽

- Do not apply heat directly to the joint area. Because brazing works by capillary action, heat must be applied uniformly to a broad area surrounding the joint, allowing braze alloy to become fluid and be drawn into the joint area.⧼thumbs_response⧽

- Be careful to have good ventilation wherever you are brazing. Fumes from the brazing process can be harmful.⧼thumbs_response⧽

Things You'll Need

- Non-flammable clothing

- Gloves

- Safety goggles

- Degreasing solvent

- Sandpaper, emery cloth, grinding wheel, or file

- Brazing rod and flux paste or flux-coated rods

- Brush

- Torch

- Wire brush

- Rust-resistant coating (optional)