wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 18 people, some anonymous, worked to edit and improve it over time.

There are 7 references cited in this article, which can be found at the bottom of the page.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 90% of readers who voted found the article helpful, earning it our reader-approved status.

This article has been viewed 366,454 times.

Learn more...

Aluminum is a real challenge to join without specialized welding equipment. You will need to track down a specialized solder or brazing alloy intended for use on aluminum, or for joining aluminum to a different metal depending on your project. Once you've obtained the solder online or from an unusually well-stocked hardware store, the main challenge lies in working quickly enough to join the aluminum immediately after the aluminum oxide layer has been scraped off the surface.

Steps

Getting Started

-

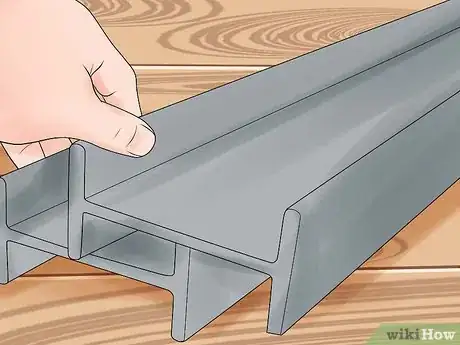

1Identify the alloy if possible. Pure aluminum can be soldered, although it is not an easy metal to work with. Many aluminum objects are actually aluminum alloys. Most of these can be soldered the same way, but a few of them are very difficult to work with and may need to be taken to a professional welder. If the aluminum alloy is marked with a letter or number, look it up to see if there are any specific requirements. Unfortunately, unlabeled aluminum alloys can be difficult to tell apart, and professional identification guides are likely only worthwhile if you are running a business.[1] You may need to just dive in and test your luck.

- If you are joining aluminum to another metal, the aluminum's properties are usually the limiting factor, so precise identification of the other alloy's composition may not be necessary. Note that some combinations such as aluminum-steel are extremely difficult or may require specialized welding methods instead of solder.

-

2Select a low-temperature solder. Aluminum melts at a relatively low 1220ºF (660ºC),[2] which combined with its high heat capacity makes it almost impossible to solder using general-purpose solders. You'll need a specialized solder with a significantly lower melting point, which you may need to order online. Typically, an alloy made from some combination of aluminum, silicon, and/or zinc is used for this purpose, but check the label to make sure it is intended for your type of join, such as aluminum-aluminum or aluminum-copper.

- Technically, filler metals that melt above 840ºF (450ºC) join by brazing instead of soldering. In practice, these are often sold as solders, and the process is similar. Brazing creates a stronger bond, but soldering is preferred for pieces with electrical circuits or other delicate materials.

- Avoid solders that contain lead whenever possible.

Advertisement -

3Pick a flux. Much like the solder, the flux should be specialized for aluminum or for the combination of metals you plan to join. The easiest option is to purchase the flux from the same source as your solder, as they are likely intended to work together. The recommended temperature for the flux you select should be similar to the melting point of your solder. Select a brazing flux if the solder you chose melts above 840ºF (450ºC).

- Some brazing fluxes are not intended for use on thin aluminum sheets or wire. Look for "dip brazing" flux for these applications instead.

-

4Choose a heat source. You can use a soldering iron for joining aluminum wire, but other jobs will require the use of a torch. Typically, a low-temperature torch is used, with a flame tip that reaches 600 to 800ºF (315–425ºC).

- If torch use is not feasible in your work space, try a 150 watt soldering iron.

-

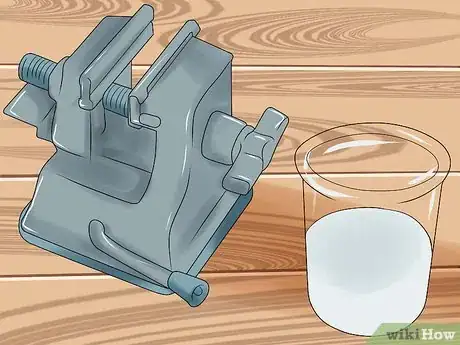

5Gather optional materials. You'll need a clamp if you are joining more than one piece of metal, rather than making small repairs in a single object. A pickling solution, or special substance for cleaning off post-soldering oxides, is also recommended. Some resin-based fluxes must be cleaned off with acetone.

-

6Set up a safe work area. Protect yourself from toxic fumes by wearing a respirator mask and working in a well-ventilated area.[3] A face mask or goggles are highly recommended, as are heavy leather gloves and non-synthetic clothing.[4] Keep a fire extinguisher nearby and work over non-flammable surfaces only.

Joining the Aluminum

-

1Pre-solder each part of difficult joins (optional). Large joins or difficult combinations such as aluminum-steel can benefit greatly from "tinning," or the application of a small layer of solder to each component part. Follow the instructions below for each piece you plan on joining, then repeat with the pieces clamped together.

- Ignore this step if you are using solder to repair a crack or hole in a single object.

-

2Clean the aluminum with a stainless steel brush. Aluminum forms aluminum oxide rapidly upon contact with air, and this thin layer of oxide cannot be joined.[5] Scrub it off thoroughly with a steel brush, but read the instructions below first. Be prepared to clean, flux, and solder in rapid sequence so the oxide does not get another chance to form.

- Old aluminum with heavy oxidization or other surface debris may require sanding or grinding, or wiping with isopropyl alcohol and acetone.

-

3Clamp the base metals together. If you are connecting two pieces rather than repairing a single object, clamp the two pieces together in the position you wish to join them. There should be a slight gap between them for the solder to flow along, but keep this to 1/25" (1 mm) or less.

- If the pieces do not fit together smoothly, you will need to make the joined areas smooth through sanding or bending.

- Because the aluminum should be given as little chance to oxidize as possible, you may wish to clamp the pieces together loosely, clean them while they are clamped, then tighten the clamp.

-

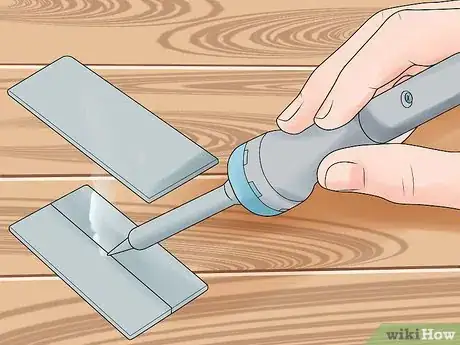

4Apply the flux. Immediately after cleaning the metal, apply the flux along the area to be joined using a rod of solder or a small metal tool. This will prevent further oxide from forming and draw the solder along the length of the join.

- If soldering wires, dip them in the liquid flux instead.

- If your flux came in powder form, refer to the label for mixing instructions.

-

5Heat the metal. Use your torch or soldering iron to heat the metal object adjacent to the join, starting at the lower end of the workpiece. A direct flame on the repair area is likely to overheat the solder and flux. If using a torch, hold the torch tip at least 4 to 6 inches (10.2 to 15.2 cm) away from the parent metal.[6] Move the heat source constantly in small, slow circles to evenly heat the area.

- Soldering irons may take up to ten minutes to heat up before they can be used.

- If the flux turns black, let the area cool, clean it & start over.

-

6Apply solder.[7] Most fluxes will bubble and turn light brown when they have reached the correct temperature. Drag the rod or wire of solder material over the join, continuing to heat the area indirectly from the opposite side of the metal, or a nearby surface. It should be drawn along the gap already, but constant, slow movement on your part is necessary to create an even bead. Making an attractive and strong even join can take practice if you haven't done much soldering before.

- If the solder will not bond to the aluminum, it could be that more aluminum oxide formed on the surface, in which case it needs to be cleaned and immediately soldered again. It could also be that you have the wrong type of solder, or your aluminum is actually a difficult-to-join alloy.

-

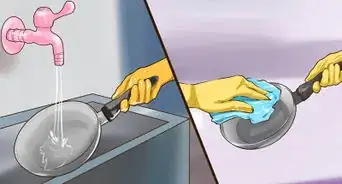

7Remove the excess flux and oxide. If you are using a water-based flux, the flux can be rinsed off with water once the finished piece has cooled. If you are using a resin-based flux, use acetone instead. After the flux is removed, you may wish to put the finished piece in a "pickling solution" to remove any oxides that may have been created under the high heat.[8]

Community Q&A

-

QuestionDo I need special tools to solder wire to an aluminum sheet?

Community AnswerJust flux for aluminum soldering and lead-free solder. Avoid lead in any case. Zinc-tin solder is the preferred option. One example of flux is Russian F61A. Practice first on sample and smaller pieces of original work to understand how it works.

Community AnswerJust flux for aluminum soldering and lead-free solder. Avoid lead in any case. Zinc-tin solder is the preferred option. One example of flux is Russian F61A. Practice first on sample and smaller pieces of original work to understand how it works. -

QuestionUnder what conditions could I pour molten lead on an aluminum surface and obtain a permanent bond?

Community AnswerIt would depend on your definition of "permanent", how thick of a lead layer, and how harsh an environment the "alumi-lead" has to survive in. Typically aluminum does not "play well" with other metals. The vapor deposit method might work if you need only a very thin layer. There is also a process in development by Luminor that can "paint" metal onto another surface, but I don't think it is widely available.

Community AnswerIt would depend on your definition of "permanent", how thick of a lead layer, and how harsh an environment the "alumi-lead" has to survive in. Typically aluminum does not "play well" with other metals. The vapor deposit method might work if you need only a very thin layer. There is also a process in development by Luminor that can "paint" metal onto another surface, but I don't think it is widely available. -

QuestionWhat comprises a pickling solution?

Community AnswerThere are a number of methods for pickling aluminum. One is to submerge the part in a boiling or near boiling 5% solution of sodium hydroxide in water for up to 20 minutes, until the part has a thick black coating of sodium aluminate, then briefly rinsing the part in room temperature water, next in a cold solution of up to 50% nitric acid in water to remove the black coating, & then a final rinse in warm water to remove the acid.

Community AnswerThere are a number of methods for pickling aluminum. One is to submerge the part in a boiling or near boiling 5% solution of sodium hydroxide in water for up to 20 minutes, until the part has a thick black coating of sodium aluminate, then briefly rinsing the part in room temperature water, next in a cold solution of up to 50% nitric acid in water to remove the black coating, & then a final rinse in warm water to remove the acid.

Warnings

- When using solder and flux, do so in a well ventilated area as flux fumes are toxic. Solders with lead or cadmium are also toxic and should only be used in well ventilated areas, and never for drinking water plumbing applications.⧼thumbs_response⧽

Things You'll Need

- Heat source: propane torch or soldering iron

- Specialized solder for aluminum, such as 91%Sn/9%Zn or 85%Sn/15%Zn.

- Aluminum flux: usually based on temperature range and the base metal you are working with. Aluminum fluxes are also hard to find in local stores and are usually best found online.

- Stainless steel brush

- Clamp

- Acetone (for resin-based flux)

- Pickling solution

- Face shield or goggles

- Respirator mask

- Gloves

- Fire extinguisher

References

- ↑ http://www.aluminum.org/news/aluminum-association-completes-2013-edition-aluminum-standards-and-data

- ↑ https://app.aws.org/wj/2004/02/046/

- ↑ https://safe-welding.com/welding-aluminium-dangerous-formation-of-oxides-and-ozone/

- ↑ https://awo.aws.org/2014/01/safety-first-what-you-need-to-know-about-aluminum-welding/

- ↑ https://www.youtube.com/watch?v=bFf3zO2Ys64

- ↑ http://www.kappalloy.com/faq.php

- ↑ https://www.youtube.com/watch?v=bFf3zO2Ys64

- ↑ https://blog.lucasmilhaupt.com/en-us/about/blog/cleaning-the-brazed-joint

About This Article

To solder aluminum, start by setting up a well-ventilated work space and putting on a respirator mask, goggles, and gloves to protect yourself from the fumes and high temperatures. Next, clean the aluminum with a stainless steel brush, and clamp together the pieces you’re joining. After that, apply a flux made specially for aluminum, then heat the aluminum until the flux bubbles and turns light brown. Finally, drag the solder across the places where you want the aluminum pieces to be joined together. For tips on how to remove the excess flux after soldering your aluminum, keep reading!