wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, volunteer authors worked to edit and improve it over time.

This article has been viewed 184,053 times.

Learn more...

Most motorcycle enthusiasts trace choppers back to World War II vets coming home from tours of duty, particularly in Europe, who wanted to rekindle some of the two-wheeled thrills experienced overseas. However, the US manufacturers produced bulkier bikes with bodywork, particularly fenders and bumpers, that resembled automobiles more than Europe’s lighter bikes. So riders started chopping off parts to lose weight and gain speed. Choppers were born. You can unleash the inner artist yourself, pursuing any of four main avenues to build a chopper motorcycle.

Steps

Modifying a Motorcycle

-

1Take advantage of an already-working motorcycle and chop it to taste.

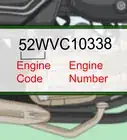

- Running the original motorcycle allows you to maintain registration or licensing more easily, as you are running an original manufacturer’s vehicle with their registration numbers.

- Ride the motorcycle, get a feel for what you like "as is" and what you want to modify.

- Modify any original parts, taking advantage of the original mounting brackets and hardware.

- Add or subtract parts as time and money allow, while keeping the bike in running order, to minimize down time and prolong your riding enjoyment.

-

2Purchase and customize the rolling chassis. A rolling chassis includes the frame, both wheels, the front forks, handlebars and clamps that hold the bars to the forks, and customize with body work and drivetrain.

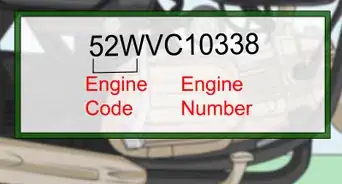

- The registration numbers belong to the frame, so you can start either with a salvage project from an original manufacturer, or with an aftermarket manufacturer specializing in rolling frames.

Advertisement -

3Install the drivetrain of your choice.

- As the wheels, front suspension and frame already work together as a unit, you know what drivetrain will fit the basic dimensions of your bike, lessening the guesswork involved.

Building a New Kit Bike

-

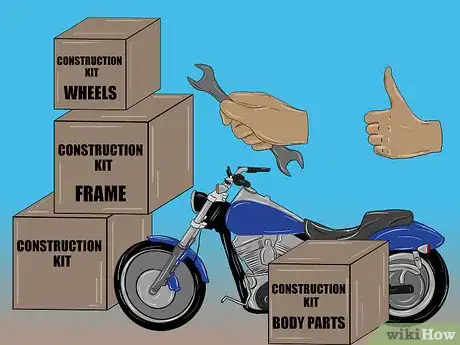

1Combine the challenge of building a new chopper from the ground up with the convenience of sourcing all the major components from one manufacturer.

- This option may appeal to first-time builders in particular, as all the parts are designed and built to fit together; the manufacturer can address problems or warranty issues.

-

2Prepare for added time, effort and space.

- Have a well-lit, uncluttered space you can dedicate solely to the project. You will be building in stages, leaving you with a partially assembled chopper in this space for a long period of time.

- This option may cost the most up front, as you will be purchasing most or all the components of a new motorcycle at the same time.

Building With Salvaged Parts

-

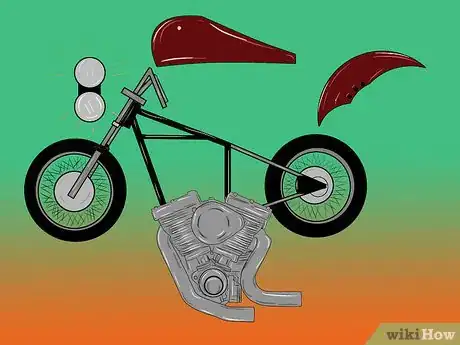

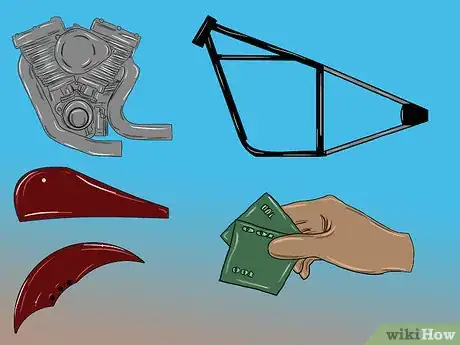

1Start with one object, such as a gas tank, carburetor or set of wheels, and build a custom chopper around the theme imagined from that part.

- Usually only advanced mechanics take on this option, as it entails a lot of time, resources and skill. Experienced chopper builders also understand what works or fits together and what doesn’t.

-

2Work with a trusted source for parts.

- Look for a large motorcycle shop or even a junkyard that has a dedicated area for motorcycles as a starting point, both as a parts source and a place to turn to for advice.

-

3Develop a solid relationship with a speed shop.

- Get mechanical assistance in building or rebuilding drivetrains, creating or modifying custom body parts and painting or plating bare metal.

Community Q&A

-

QuestionWhat is a motorcycle?

Community AnswerIt is a vehicle with two wheels that is powered by a motor, and can carry one or two people.

Community AnswerIt is a vehicle with two wheels that is powered by a motor, and can carry one or two people. -

QuestionWhat's a motorcycle kit?

Community AnswerIt is a prepackaged way to make a chopper. An example is a kit engine which contains parts likes pistons, cylinder, gears and many other parts. It also contains a specific number of tools and materials for fitting.

Community AnswerIt is a prepackaged way to make a chopper. An example is a kit engine which contains parts likes pistons, cylinder, gears and many other parts. It also contains a specific number of tools and materials for fitting. -

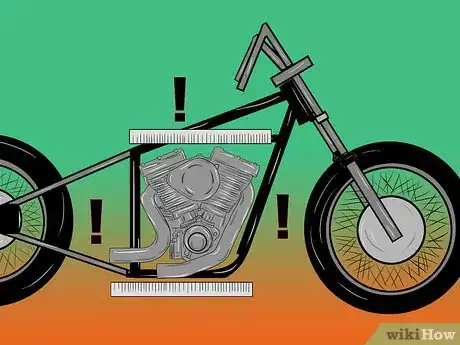

QuestionHow can I make a frame for this motorcycle?

Kousthub SarmaCommunity AnswerYou may just mold a strong metal into a polygon keeping the size of your engine in mind. The frame should exactly fit under the driver seat depending on the model. It is better to keep the height low to increase the ground clearance and reduce risk of mid air accident. The strength and structure matters a lot, as well as the space given to engine, so that you can prevent resonance and loose contact or wire disconnection. Contact only if necessary.

Kousthub SarmaCommunity AnswerYou may just mold a strong metal into a polygon keeping the size of your engine in mind. The frame should exactly fit under the driver seat depending on the model. It is better to keep the height low to increase the ground clearance and reduce risk of mid air accident. The strength and structure matters a lot, as well as the space given to engine, so that you can prevent resonance and loose contact or wire disconnection. Contact only if necessary.

-Step-13.webp)

-Step-17.webp)