X

wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 19 people, some anonymous, worked to edit and improve it over time.

There are 7 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 193,292 times.

Learn more...

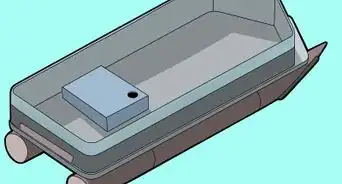

Fiberglass is used to build boats for many reasons. Chief among these are its durability, but also its easy to repair. You can patch boat holes in an afternoon and fiberglass a boat in just a couple of days. This article covers how to fiberglass a boat using epoxy resin.

Steps

-

1Prepare the boat for fiber-glassing. Before you begin the process of applying fiberglass to your boat, you need to prepare the boat. There are several preparations to consider.

- Removing extra items from the bottom of the boat. You should remove the keel, any lift stakes or rails, and anything else that should not be covered in fiberglass.

- Repair any holes with appropriate filler. To repair a hole, cut out the damaged section, wash and apply a dewaxing solvent, grind the area with a disk sander, apply a laminate or acrylic patch to the outside of the hull with polyvinyl alcohol (PVA) mold release, apply a fiberglass patch measured and cut to fit the hole. Apply resin, repeat the fiberglass/resin application process as necessary and add hardener.[1]

- Clean the hull of the boat. The hull should be clear of debris, barnacles, dust, dirt and mold.

- Sand the boat. For best results, the surface should be a little rough.[2] Too much sanding can cause rippling.

-

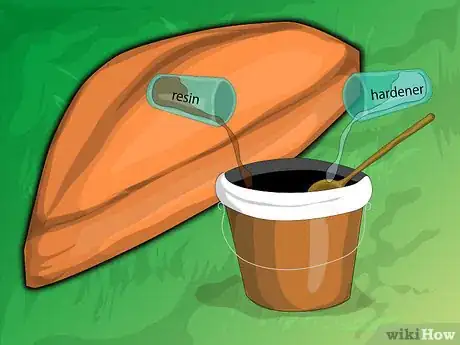

2Mix resin and hardener according to package directions and pour the solution into a paint tray immediately. After about 30 minutes, the solution should be significantly hardened and ready to apply to the hull of the boat.Advertisement

-

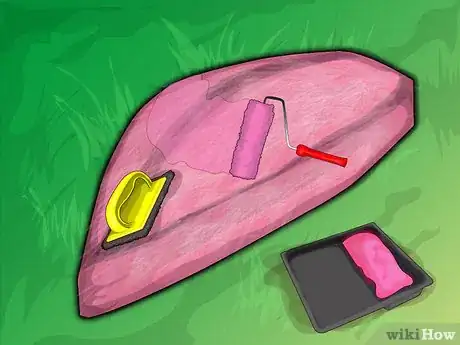

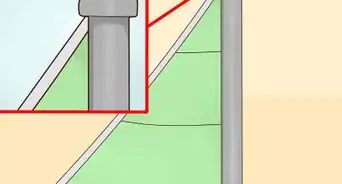

3Apply the first coat of resin. This first coat is called the seal coat. Using a foam roller, apply firm pressure and directional strokes to spread the resin as evenly as possible. Wait for the surface to no longer be tacky before doing additional work on the hull.[3]

-

4Prepare and install the fiberglass cloth. Cut fiberglass cloth to the shape needed.[4] Attach the fiberglass cloth to the hull using tape, tacks or staples.

-

5Apply a second coat of resin. This coat is called the bond coat. If you have waited for a while, consider sanding the hull again. Working from one end of the hull to the other, apply the bond coat over the fiberglass cloth. Remove the material you have used to attach the fiberglass cloth to the boat before the bond coat sets up completely.[5]

-

6Apply another coat of resin. This coat is known as the fill coat. Wait for the previous coat to set up hard. If you have waited a significant period of time, clean and sand the hull again.[6]

-

7Apply a final coat of resin. The finish coat should be smooth and even, but should also be thick enough to allow you to sand the hull evenly without damaging the cloth.

-

8Sand the hull. Give the final coat enough time to dry, preferably overnight. Use lower grit paper at first and finish with a higher grit paper.

-

9Apply a protective agent. This can be paint or another boat hull finish. Apply the protective agent according to the package directions.

Advertisement

Community Q&A

-

QuestionI have accidentally drilled a 3mm hole where the boat goes on the skidbar; how can I repair it?

Community AnswerClean the hole, rough up around hole, and fill with dowel rod sand. Go over with a fiberglass mat and resin.

Community AnswerClean the hole, rough up around hole, and fill with dowel rod sand. Go over with a fiberglass mat and resin. -

QuestionWhat is wrong if my fiberglass resin is still tacky after several days?

Community AnswerProbably not enough hardener, or the hardener was mixed in unevenly and you had some portion of the resin mix that has no hardener in it. You might have to grind it off and start again or get it out using solvent. Another reason might be temperature. It’ll need a certain amount of heat to cure. It’ll take a long time to cure in the cold.

Community AnswerProbably not enough hardener, or the hardener was mixed in unevenly and you had some portion of the resin mix that has no hardener in it. You might have to grind it off and start again or get it out using solvent. Another reason might be temperature. It’ll need a certain amount of heat to cure. It’ll take a long time to cure in the cold. -

QuestionHow do I repair an old fiberglass boat transom?

Community AnswerCut out the inside wall, remove wood, clean out debris, cut new wood to size, install fiberglass mat, and resin several coats.

Community AnswerCut out the inside wall, remove wood, clean out debris, cut new wood to size, install fiberglass mat, and resin several coats.

Advertisement

Things You'll Need

- Dewaxing solvent

- Belt sander

- Mold release

- Fiberglass cloth

- Fiberglass resin and hardener

- Protective agent

References

- ↑ https://www.familyhandyman.com/automotive/how-to-repair-fiberglass/

- ↑ https://www.fibreglast.com/product/fiberglass-repair-composite-repair/Learning_Center

- ↑ https://www.glen-l.com/how-to-fiberglass-a-plywood-boat/

- ↑ http://www.boatus.com/boattech/casey/fiberglass-repair.asp

- ↑ https://www.epoxyworks.com/index.php/fiberglassing-a-woodstrip-hull/

- ↑ https://www.epoxyworks.com/index.php/fiberglassing-a-woodstrip-hull/

- http://www.glen-l.com/methods/how-to-fg.html

- http://www.boatus.com/boattech/casey/17.htm

About This Article

Advertisement