This article was co-authored by Keila Hill-Trawick, CPA. Keila Hill-Trawick is a Certified Public Accountant (CPA) and owner at Little Fish Accounting, a CPA firm for small businesses in Washington, District of Columbia. With over 15 years of experience in accounting, Keila specializes in advising freelancers, solopreneurs, and small businesses in reaching their financial goals through tax preparation, financial accounting, bookkeeping, small business tax, financial advisory, and personal tax planning services. Keila spent over a decade in the government and private sector before founding Little Fish Accounting. She holds a BS in Accounting from Georgia State University - J. Mack Robinson College of Business and an MBA from Mercer University - Stetson School of Business and Economics.

There are 8 references cited in this article, which can be found at the bottom of the page.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 100% of readers who voted found the article helpful, earning it our reader-approved status.

This article has been viewed 140,549 times.

Inventory is the physical supplies you sell or use to provide services as part of your business. Your inventory is one of your most valuable assets, and keeping track of it accurately is essential to running your business smoothly. Whether you use an electronic inventory tracking system or do everything yourself manually, maintaining accurate inventory records will contribute to your business' success. Note that a discussion of inventory can refer to the tangible goods your business has on hand, or it can refer to the accounting values for inventory. This article will discuss controlling physical inventory.

Steps

Developing an Inventory Tracking Method

-

1Choose an inventory monitoring method. There are generally two options for inventory tracking — system or manual. Inventory systems are generally software products that connect to your accounting system or cash register and update your inventory records as you make sales and buy new product. You can also track your inventory manually by keeping an inventory log on paper or in an excel workbook, and by updating your inventory yourself periodically.[1]

- When you're deciding on your monitoring method, consider how often you need to access inventory records and what kind of inventory you own.

- You'll also need to factor in how much you can afford to spend on the system.

- If you are a small business and your inventory is not dangerous or unusually valuable, you should consider tracking your inventory manually to save costs.

- If you run a large business or have valuable or dangerous inventory, consider paying to use an inventory system.

-

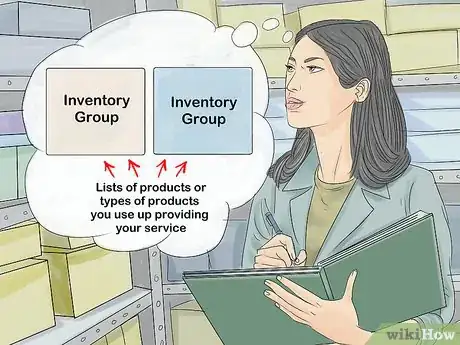

2Create inventory groups and tags. Make a list of all the products or types of products you have in your inventory, and choose a name for each one.[2] You can be as detailed as you would like, but each item in your inventory should fit into one (and only one) of these inventory groups. Include any inventory items you will need in the future or simply don't have on hand on inventory day, and create groups for those items as well.

- Don't make your labels too broad. If you run a cafe that keeps whole, low fat, and soy milk on hand, don't create one large inventory group called "milk."

- If you sell rain boots, you may organize your inventory by gender and size, but not color.

- Only group the things you use providing your service, like coffee in a coffee shop and clothing in a boutique. Don't include equipment like a coffee grinder or a dressing room chair.

Advertisement -

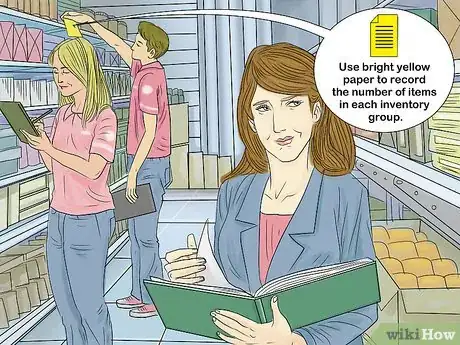

3Count your inventory. Dedicate as much time as you need to perform an initial count of how many items you currently have in each group. Separate your inventory into the groups you decided on, and mark each group once you have counted it. If your inventory is especially valuable, complex, or dangerous, you might count it twice to ensure accuracy. You may need to involve your employees if you have a large business and a lot of inventory.

- Physical inventory counts should be performed regularly to validate automated inventory counts. These counts allow you to identify discrepancies due to theft, spoilage, or obsolescence.

- Use visual cues to make inventory counting easier. For example, if you count a group of objects on a shelf, write the number on yellow paper and tape that to the shelf.

- If your supplies come in larger packages, like boxes filled with 10 rolls of tape each, count the number of boxes and multiply that by 10 to get your total.

- If you run a business where you sell food, counting inventory can be especially challenging. You may wish to measure items by weight, unit, or percentage.

-

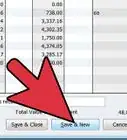

4Record your inventory count. If you are going to track inventory manually, use a notebook as an inventory log, or create an excel spreadsheet. Create a row for each group in your system, and then write the quantity in that group from your count. If you are using an inventory system, the system will guide you through creating labels for each group and recording the quantity on hand for each of these groups.

Implementing Your Inventory Tracking Method

-

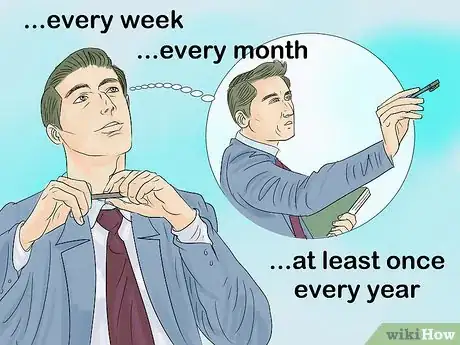

1Schedule your inventory updates. To maintain accurate inventory records, you'll need to add new inventory when you make purchases and reduce inventory when you make sales. If you are using an electronic inventory system, you will likely have the option of connecting your system to your cash register, and using continuous inventory recording.

- If you are tracking inventory manually, decide whether to update your inventory records when you purchase new inventory, or just to count all your inventory at regular intervals.

- Regardless, you should do a physical count at least once a year. Depending on your business, you might even want to do this as often as once a week.

- If counting your whole inventory seems unrealistic, try cycle counts, where you only count a single inventory group at a time. Constantly rotate through groups to keep your inventory current.[3]

-

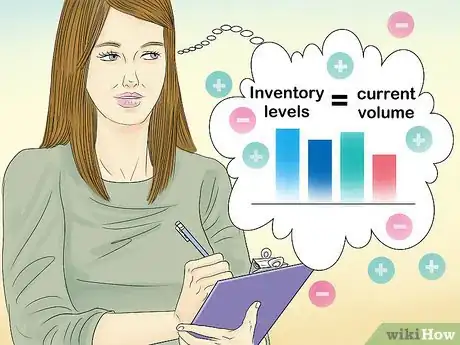

2Make periodic inventory adjustments. Each time you perform a count, adjust your recorded inventory levels to reflect the current volume. If you use a manual system, update each item in your inventory with the current quantity you have on hand. If you use an electronic system, it will likely guide you through the steps of performing adjustments, but you will do the same function of increasing or reducing the inventory level for each of your items, based on your counting.

- This is also a good time to monitor your inventory usage. If your inventory level is a lot lower than you expected, consider whether you are losing inventory to theft.

- You might also discover that your operations require more supplies than you expected, or you could lose inventory due to damage or defect.

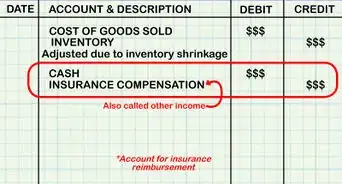

- Loss of inventory due to theft, damage, defect, etc. is called shrinkage, and you should aim to minimize shrinkage while still allowing for reasonable error.[4]

Establishing Inventory Controls

-

1Determine your inventory control needs. The level of control you establish should be based on the value and risk associated with your inventory. If your inventory includes prescription medication, ammunition, or other dangerous goods, you should develop strong controls. If your inventory is food, beverage, or other low-cost items, your controls can be less stringent because your inventory isn't as risky.

- If you have employees, you may want to secure your inventory against theft or misuse.

- Remember that it is possible to over-control your inventory — the more complex your controls, the higher the cost associated with them.

-

2Separate your inventory from business activity. By storing your inventory in a separate place from where you do business, you ensure that it isn't readily available or visible at all times. For example, you may have a large fridge and freezer in the back part of your coffee shop, and employees may bring milk from that fridge to the bar when they need to. Having a separate storage area can make it easier to keep track of your inventory.

-

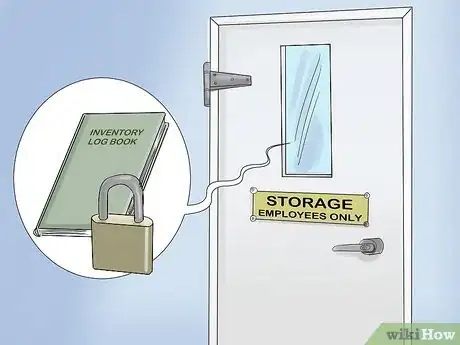

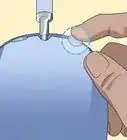

3Restrict access to your inventory storage area. This can be as simple as having an "employees only" sign outside your inventory storage room, or as complex as requiring a key or employee badge to get in.[5] The level of restricted access to your inventory should reflect the risks associated with the items you have on hand. Many inventory systems for sale provide restricted access by requiring a passwords or badge swipes to access a locked inventory storage room.

-

4Record inventory usage. You can require employees to log when they take an item out of inventory for use in your business. A simple form of recording is a check-out sheet, so employees write down their name, the date, and the amount of inventory they remove. A more complex form of recorded inventory use is computer access system, where employees must log in with their unique ID and scan each inventory item they pull.

- Keeping a log of when things were removed can reduce theft and makes sure you have a record of who took what when.

-

5Perform inventory audits and cycle counts. If you use an inventory system that automatically updates your inventory volume each time you make a sale, you can conduct random inventory audits and compare the count at audit to the amount recorded in your inventory system. Periodic physical counts are necessary to assure that accounting records and physical inventory agree.

- To be effective you don't need to audit each and every inventory group, you can just choose a few different groups to audit each time.

- Note items that are consistently under during audit, and consider further restricting access to these items.

-

6Establish inventory system controls. Whatever you use to record your inventory levels should be controlled to prevent anyone from wrongfully or accidentally changing your records. If you use an electronic inventory system, make sure you set up a secure username and password that only you know. If you use an excel spreadsheet to keep track of inventory, store the spreadsheet on a secure computer that only you have access to.

- Similarly, if you use a notebook, keep that notebook in a secure place.

- If you have an electronic system and your employees need to access it, provide them with their own login unique login information.

-

7Walk the talk. If your employees know you are serious about inventory accuracy and will investigate discrepancies, they will be more likely to take your system seriously and follow it. To make this clear, provide adequate training to all your employees on your inventory system, and hold your employees accountable for following these instructions. Inform employees about the controls you have over inventory and tell them you plan to monitor inventory levels for theft and misuse.[6]

- Above all, take inventory accuracy seriously yourself. The worst thing you can do is model for employees a casual attitude regarding your inventory — if you don't take it seriously, they certainly won't.

Restocking Your Inventory

-

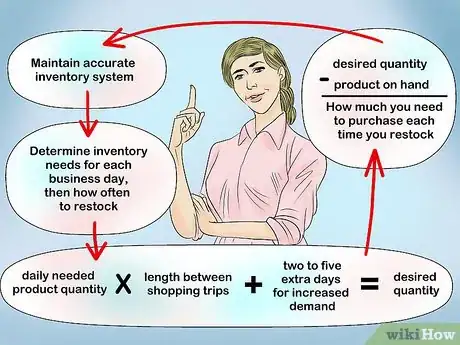

1Plan your purchasing cycle. Use your inventory system to plan your purchases so you don't end up with more inventory than you need. Determine how much of each product group you need for each business day, then decide how often you will restock. Multiply the daily needed quantity by the length between your shopping trips, and add two to five extra days for increased demand. This is how much of the product you need on hand after purchase.

- To determine how much you need to restock, calculate how much of the product you currently have on hand, and subtract that amount from your desired quantity.

- For instance, if you use 1 bottle of cleaner a day and you restock once a month, you'd need 33 bottles after restock. If you have 7 bottles left when you order, you'd purchase 26 bottles.

- The greater the fluctuation in demand for your products, the more extra product you should have in addition to what you need to run your business.

- Stock up extra on products that are hard to source, as well.

-

2Seek opportunities to automate if you have an inventory system. For instance, you can program your inventory system to alert you whenever you reach a low quantity in a specific group. Some systems will even order inventory for you, just based on the level of supply you have on hand. This method is more expensive than manual inventory and purchasing, but in a large business with lots of inventory, it can save a significant amount of time and headache.

- If you have an automated inventory system where you scan each item as you bring it out of storage, your system may allow you to automate restock purchases.

- For instance, you could program the system to order 30 new shampoo bottles from your vendor whenever you get down to five bottles in inventory.

- Even if you don't automate purchases, your inventory system can likely alert you when your product is running out so you can place a manual order.

-

3Adjust your purchasing based on your experience. As you run your business over time, you will get more and more accurate at predicting your inventory needs. If you regularly notice you have a lot of product on hand when you go to make purchases, reduce your necessary inventory level.[7] You only want to have a slight amount more than you need, because you pay for the storage and potential waste costs of your unused inventory.

References

- ↑ http://www.infoentrepreneurs.org/en/guides/stock-control-and-inventory/#4

- ↑ http://www.accountingtools.com/procedure-inventory-count

- ↑ http://www.inc.com/resources/retail/articles/200506/counting.html

- ↑ http://www.accountingcoach.com/blog/what-is-inventory-shrinkage

- ↑ http://www.accountingtools.com/inventory-internal-controls

- ↑ http://www.inventoryops.com/guide_inv_acc.htm

- ↑ Keila Hill-Trawick, CPA. Certified Public Accountant. Expert Interview. 30 July 2020.

- ↑ http://www.retaildoc.com/blog/taking-the-hassle-out-of-physical-inventory-and-why-its-worth-it

About This Article

If you want to accurately maintain your inventory, you should start by grouping your items using labels. For example, if you sell different varieties of coffee, you might organize your inventory by strength, flavor, or caffeine levels to ensure that you offer something for everyone. Then, record your inventory count using either a notepad or excel spreadsheet so you have something to refer back to. To keep your inventory accurate, it’s important to schedule time to update your inventory whenever you purchase new stock or make new sales, you could do this every week, month, or year! For more advice from our Financial co-author, including how to accurately restock your inventory, keep reading!