This article was co-authored by Karin Lindquist. Karin Lindquist earned a BSc in Agriculture as an Animal Science major from the University of Alberta, Canada. She has over 20 years of experience working with cattle and crops. She's worked for a mixed-practice veterinarian, as a sales representative in a farm supply store, and as a research assistant doing rangeland, soil, and crop research. She currently works as a forage and beef agriculture extension specialist, advising farmers on a variety of issues relating to their cattle and the forages they grow and harvest.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 89% of readers who voted found the article helpful, earning it our reader-approved status.

This article has been viewed 217,930 times.

Preserving feed for livestock doesn't always mean putting up sun-dried hay. Silage is also made as a chopped, fermented feed source, primarily from annual crops like corn, barley, sorghum, oats, millet, and occasionally canola and wheat. Silage is made by packing the chopped crop into a "pit" and packing it down well so that any oxygen pockets are eliminated. Oxygen pockets encourage spoilage of the feed. Silage and haylage can be interchangeable, especially since haylage or baleage involves the same process of ensiling to preserve feed for livestock. However, silage more relates to annual crops than perennial forages. How to make silage is described in the steps below.

Steps

Before the Harvest

-

1Plan ahead. You will need to know when the right time to start silaging so that you get the crop cut at the right stage for the best feed quality possible.

- Timing is crucial to get the crop cut at the right stage, harvest soon after, and have someone packing the pit as the loads are coming in. The pit will need to also be covered as soon as possible to avoid losses with spoilage.

- You must have the right equipment and enough silage plastic available ahead of time so that you are not scrambling and trying to beat a fast-closing window of opportunity to get your crop in.

- If you have not yet found a site for and installed a concrete bunker, or dug into the ground an open three-sided pit designed for storing silage, you will need to have this arranged and completed well in advance of silage-making season. Or, if you do not have a bunker or pit dug out and prepared for proper ensiling, you need to find a place where you can create a silage pile that is well-drained and easily accessible during times when you need to access it without much trouble.

-

2Assess the crop. For most cereal crops, the best time to cut is when they are at the soft-dough stage. The majority of the plant should still be green, but with a bit of yellowish tinge, especially on the heads of the plant.

- To test crop stage, squeeze a random kernel between your fingers to see how soft it is. At the soft-dough stage you should get a white, soft paste-like substance coming out from the seeds. If it's more liquid than paste, the crop isn't quite ready yet, but getting very close.

- Corn will be at the same stage when it is ready to be harvested for silage. However, to test if corn is ready, take an ear of corn, tear off the husks and break the cob in half. An old rule of thumb is to look for the "milk line" (the line made where the solid and liquid parts of the kernels divide, and tends to progress from the outer edge of the kernel in towards the cob). This milk line should be half to two-thirds of the way in to the cob (the kernels are 2/3 yellow and 1/3 white, for example)[1] .

- Weeds are a bit of a non-issue with a silage crop. It's being made into feed, not being sold for grain, and the animals aren't going to judge if they find a tiny bit of wild buckwheat in with the rest of the feed.

Advertisement -

3Cut the crop into swaths. Unlike with making haylage, the best machine to use to cut a crop with is a swather, not a hay mower. A windrower may be all right, but when cutting a thicker and taller crop like barley or oats, a swather is built for the heavier tonnage you will be getting off cropland than you would a perennial forage stand, usually. Also, a swather will not shred seeds off of the crop like you may find happen more often with a windrower.

- It will be a different story with corn and sorghum, or sorghum-sudan grass. This step will not be needed for this type of crop because the swaths will be to large and difficult for a forage harvester to get through. Instead, these crops will be straight-cut, with a header that is suited for large-stemmed crops like corn. Straight-cutting small-cereals like barley and oats for silage is not an issue and an option to consider. With swathing, though, it actually allows the crop to dry down a bit more than if left standing, allowing you to harvest it at a lower moisture than what you would get if harvesting it as a standing crop.

- Straight-cutting small-cereals like barley and oats for silage is not an issue and an option to consider. With swathing, though, it actually allows the crop to dry down a bit more than if left standing, allowing you to harvest it at a lower moisture than what you would get if harvesting it as a standing crop.

- Silage should be put up at around 60 to 70% moisture for best preservation activity. A higher moisture silage will be more prone to seepage or freezing, making things difficult for transport. Nutrients are also lost with the seepage, particularly nitrogen that has been broken down by microbes in the silage. Lower moisture may not guarantee the best fermentation activity, particularly if silage is put up at less than 40 to 45% moisture.

Harvesting Silage

-

1Allow the swaths to wilt down for about half a day before harvesting. The forage will need to be dried down to about 60 to 70% moisture before chopping for silage.

- Silage can be put up at higher moisture, but as mentioned above seepage will be an issue. Also, the low temperature fermentation activity can provide a suitable environment for undesirable clostridial bacteria that are prone to cause maladies like listeriosis and botulism.

-

2Harvest the crop. Machines called "forage harvesters" like the one in the photo above (which is a "self-propelled" harvester) are used to chop up the swathed forage and feed it out through a long, tall spout that can literally "spit" out the feed at quite a distance.

- The forage harvester's cutter blades will need to be set at the right setting so that the forage is cut at the right chop-length. For small grains, set the blades so that they are cutting up forage between 3⁄8 inch (0.95 cm) and 1⁄2 inch (1.3 cm). Larger crops like corn and sorghum-sudan should be chopped at lengths from 1⁄2 inch (1.3 cm) to 3⁄4 inch (1.9 cm).

- Since the forage harvester does not have a storage compartment on it like combine harvesters do, a truck with a silage unit on it, a tractor with a silage wagon, or a large unit designed for collecting silage from the forage harvester–called a "Jiffy wagon"–needs to be used to collect the freshly cut forage.

- The Jiffy wagon, for example, acts as the storage compartment for the forage harvester. Once full, it can be dumped into a truck as shown in the sequence of photos here.

-

3Take the freshly chopped forage to the pile or pit. Once the truck or silage wagon is full, the unit will need to be taken to the designated pit or pile area to drop off the load. Make sure the loads are placed as close to each other as possible. When first starting the pile, the first several loads must be place where the pile is going to be. After that they are placed close to the built pile, and dumped in a way that is easy for the person in the "packing unit" to move into a pile; i.e., parallel to the pile, and/or in the same direction the pile will be built up as.

- An exchange is made between the wagons and/or trucks so that the person operating the forage harvester doesn't need to stop and wait every so often. Once the first truck is full, the harvester stops briefly so that the truck can pull away and the second one moves into position. The first truck returns after dropping its load off to get another load, and so the process repeats.

-

4Pack the silage well. The silage pile must be packed very well, and should be packed down during and after each harvesting day. In a large operation where several people are employed, it would be beneficial to have one (a brave one that is not afraid of heights especially) stay behind to operate another tractor or large loader that will continuously gather and pack the pile well. Tractors with dual wheels are recommended to provide the best packing power possible.

- Packing is what helps encourage fermentation activity and discourages spoilage. The more the pile is packed down, the less pockets of oxygen there are. Oxygen pockets create spoiled feed; aerobic-loving bacteria turn it into a brown to black slimy mess, that often smells like tobacco or burnt caramel. In other words, instead of fermenting the feed (which is producing a significant amount of acid as a means to preserve the feed), the presence of oxygen decomposes it into a substance equivalent to manure. You don't want feed that is messy and gross like manure (think cow poop). If you don't like the look, feel and smell of it, neither will your animals!

- Silage piles must be longer and wider than they are tall. The higher the pile is built up, the wider the edges will need to be. A concrete bunker will control how wide you can make the pile, though you can pack several feet above, but only so much that the sides are not over-flowing.

- A rule of thumb for pile-size is larger at the base than the top; no less than 12 to 15 feet (3.7 to 4.6 m) wide at the top to prevent roll-overs or slippage from machinery; and silage piles should only be 12 to 15 feet (3.7 to 4.6 m) tall, mainly for farm safety reasons[2] .

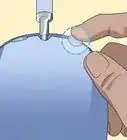

- The best way to tell if you have done a good packing job is when you try to sink your fingers into the pile. If you only get in so far as your second knuckles of your first three fingers, then the pile has been packed very well, and has potential for being good feed in the winter with minimal spoilage.

-

5Cover the pile immediately. Use the proper plastic recommended for covering silage. Often recommended and used is polyethylene plastic that may be black on both sides or white on one side and black on the other. The cheaper stuff is all black, but the better quality is the black and white plastic.

- Use 6 to 10 milliliters (0.34 fl oz) plastic. This can be found at your local farm and ranch supply store. The heavier the plastic, the more effective it is at keeping oxygen out of the pile and reducing wastage with spoiling.

- The rolls are very heavy. Use a tractor loader with bucket teeth to carry the plastic to the pit so that you can unroll and unfold it.

- A trick to use is to insert a 6 feet (1.8 m) long, heavy iron bar into the roll (like you would hanging a roll of toilet paper on a toilet-paper holder), and fashion thick wire or heavy chain that hangs on the teeth of the bucket. Hang the bar onto this.

- Important: White and black plastic must be used so that the white side is facing out, and the black against the fresh silage in the pit. The white side reflects sunlight and reduces excess heating from the sun, whereas the black side keeps heat inside.

- Trim off extra plastic and use that to cover the edges and sides that the plastic has not covered.

- Use 6 to 10 milliliters (0.34 fl oz) plastic. This can be found at your local farm and ranch supply store. The heavier the plastic, the more effective it is at keeping oxygen out of the pile and reducing wastage with spoiling.

-

6Weigh the plastic down well. Use numerous old or recycled tires all over the top part of the pile. Hay bales can also be used to hold down plastic on the sides if the silage pile is not in a bunker.

- Old tires are much more gentler on the plastic because they do not cause punctures. Punctures are a serious danger of feed spoilage.

- All sides and all parts of the pile must be covered and held down well so to ensure the pile properly ensiles and spoilage is minimized.

-

7Repair any holes immediately. Holes in the plastic can cause massive spoilage problems over time.

- Spoilage will not be localized, especially if the holes go from a tiny tear to a big rip, especially if wind is a problem.

After the Harvest

-

1Allow at least 2 weeks to pass before feeding. This will give the feed enough time to ferment and pickle, and develop that fermented sourish smell that is often associated with silaged feeds. If you wish to wait longer, then that's fine too.

-

2Take only as much as you need. Only take so much off the face as you need to feed. It may take practice to understand how much of the face to scrape down and gather for feeding, but the mathematics with calculating how much face to remove to feed a certain number of animals per feeding can be done for more accuracy, and to obtain a good pit face for your pile. Good pit faces reduce excessive spoilage or secondary heating [3] [4] .

Community Q&A

-

QuestionHow long does silage take to ferment?

Community AnswerThe fermentation process takes 10 days to 3 weeks. Silage should not be fed until after this process is completed for the best milk production and feed intake. Thus, the recommendation is to wait at least 3 weeks before feeding new crop silage.

Community AnswerThe fermentation process takes 10 days to 3 weeks. Silage should not be fed until after this process is completed for the best milk production and feed intake. Thus, the recommendation is to wait at least 3 weeks before feeding new crop silage. -

QuestionDo I have to use fermenting substances as molasses?

Community AnswerNot always. Molasses can be used, especially if the sugar levels in the grass are low. If the sugar levels are reasonably high, then the silage will ferment on its own. Adding molasses is messy and can be expensive, but will raise the quality of your silage.

Community AnswerNot always. Molasses can be used, especially if the sugar levels in the grass are low. If the sugar levels are reasonably high, then the silage will ferment on its own. Adding molasses is messy and can be expensive, but will raise the quality of your silage. -

QuestionIf I want to start a cattle and pig farm and need silage or hay, are there places where I can buy bulk loads of silage to feed my animals?

John822Community AnswerYou can by silage, but it is usually cheaper to make most of your silage yourself if you have a large group of animals.

John822Community AnswerYou can by silage, but it is usually cheaper to make most of your silage yourself if you have a large group of animals.

Warnings

- Moldy silage is particularly bad for horses. Should you find any excessive mold growth in silage, do not feed this to your horses.⧼thumbs_response⧽

- When feeding silage to livestock in the winter-time, be aware that a lot of steam will come from the hot feed. The pile will not freeze over winter; the microbes that have been busy fermenting the feed will keep the pile quite warm even when winter temperatures get well-below freezing. So when a bucket-load of silage is taken, a lot of steam may act like fog on the tractor reducing visibility.⧼thumbs_response⧽

- High moisture silage that is made at more than 70% moisture are prone to seepage losses. This seepage largely contains soluble proteins and energy that animals would need instead of the low areas down-hill from the pile or pit.

- High-moisture levels in silage can cause an abnormal low-temperature fermentation.This produces silage that has an unpleasant sour, butyric-acid smell that will severely reduce livestock consumption.

- Clostridial organisms that cause things like listeriosis or botulism can result from high-moisture silage. This is a danger to all livestock, especially horses.

- Freezing during winter months is an additional concern because it causes excessive moisture in the silage, making unloading more difficult.

⧼thumbs_response⧽ - If forage harvester machinery gets plugged up, do not get out while machines are still actively running to unplug it yourself. People have died trying to unplug machinery that wasn't turned off. There is a setting that allows you to reverse the pick-up reels to unplug the machine remotely.

- If that doesn't work, turn off all machinery completely (no engines running or PTOs still turning) before actively going in and unplugging the machine yourself.

⧼thumbs_response⧽

Things You'll Need

- Annual forage crop any size in acreage

- Swather

- Forage harvester

- Silage wagon + tractor or truck with silage-sides, or Jiffy wagon

- Silage plastic (See your local farm supply store for details.)

References

- ↑ http://www.omafra.gov.on.ca/english/crops/facts/13-051.htm

- ↑ http://www.progressiveforage.com/forage-types/silage/silage-bunkers-and-piles-a-life-and-death-matter

- ↑ http://www.dairyherd.com/quality-silage-forage/silage-pile-it

- ↑ http://www.progressivedairy.com/topics/feed-nutrition/saving-face-silage-pile-management

About This Article

To make silage, cut your crop into swaths with a swather before letting the swaths wilt for half a day. After you’ve left the crop to wilt, chop it up in a forage harvester and load the harvested crop into your silage truck. Stack your harvested crop into a large pile, then use a tractor to compress it down and get rid of as much oxygen as possible. Once the pile is complete, cover it immediately with polyethylene plastic so it can start fermenting. Use heavy objects, like old tires or hay bales, to hold the plastic sheeting down. You’ll need to leave the fodder for at least 2 weeks before using it, which will give it enough time to ferment. For tips on how to tell when it’s best to cut your crop for silage, keep reading!