wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 10 people, some anonymous, worked to edit and improve it over time.

This article has been viewed 570,221 times.

Learn more...

Firearms, more commonly known as guns, are used by outdoor hunting enthusiasts. Some hunters may choose to make their own guns, rather than buying them, to get a custom firearm. The most difficult part of building a gun is to create a barrel that will direct the fired round at the desired target. The barrel also imparts a spin to the round as it travels down the barrel, which gives the round gyroscopic stabilization as it flies to the target. Use these tips to learn how to make a gun barrel.

Steps

-

1Choose the type of steel to be used for the gun barrel. The steel chosen must have a strength of 100,000 psi (689476 kPA) to withstand the force of the gasses that propel the round. The steel should have a hardness of 25 to 32 on the Rockwell scale so that the steel is strong enough to contain the pressure necessary to propel the round through the barrel, but not so brittle that it will be harmed by the machining operations to be performed.[1] Obtain 1.25 inch (31.75 mm) rods from a specialty steel mill. Ask for a quality certification on the steel. Specify that the steel must be stress relieved at the steel mill.

- Select 4140 chrome moly steel. Chrome moly steel is the least expensive alternative. It also is easier to chemically blacken, if desired, to give a traditional look to the barrel.

- Decide on 416 stainless steel. Stainless steel is more expensive than chrome moly Steel. Stainless steel barrels have have a longer service life and are result in a more accurate firearm than do chrome moly steel barrels.

-

2Cut a piece of steel for the barrel stock. Cut a length of steel around 28 inches (71.1 cm) to 30 inches (711.2 mm to 762 mm).[2] Ensure that the ends of the barrel stock are true in parallelism to each other, are faced off and are perfectly round.

-

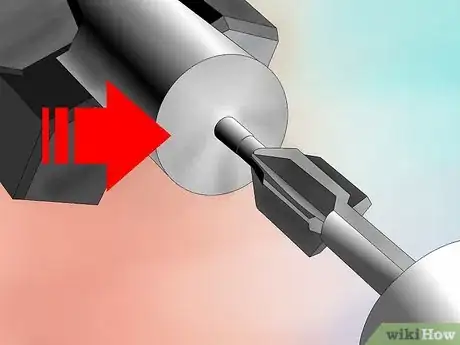

3Drill the barrel. Drill down the interior lengthwise to a diameter about 5 thousandths of an inch (0.127 mm) less than the desired finished bore diameter of the barrel. A special drill, known as a deep hole drill, must be used to drill the barrel. The deep hole drill will hold the tungsten carbide drill bit still and spin the barrel to perform the drilling.[3] Drilling will be liquid cooled and will proceed at about 1 inch (25.4 mm) per minute. Total time to drill the hole will be about 30 minutes.

-

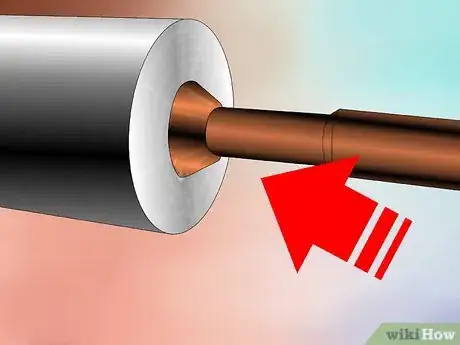

4Ream the barrel. Work a tungsten carbide bore reamer down the finished drill hole of the barrel, using liquid coolant as the reamer works. The reamer will expand the hole to the desired finished bore, and smooth the inner drilled surface of the barrel as it creates the final desired bore.[4]

-

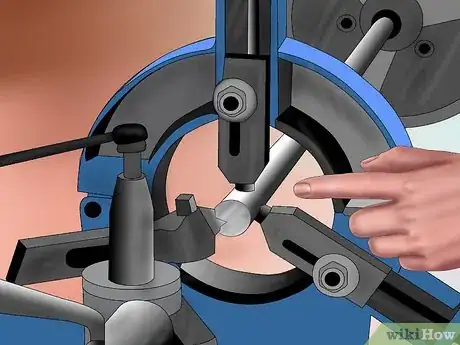

5Rifle the barrel. Rifling consists of spiral grooves in the bore, which will impart a spin to the fired round as it travels down the barrel. This spin will gyro stabilize the flight of the fired round. Determine the number of rifling grooves to be placed in the bore and the amount of twist to be put on the rifling grooves. Consult with experts in the field of gun barrel making to determine this information. Find these experts at specialty gun barrel making shops.

- Make the first rifling groove. Insert a tube mounted with the rifling hook cutter box down the bore of the barrel. Draw the rifling hook cutter box through the bore while rotating the barrel at a rate recommended by the expert to give the desired rifling spin.

- Add more rifling grooves. Index the barrel to the starting position for the next groove. Draw the rifling hook cutter box through the bore while rotating the barrel at a rate recommended by the expert to give the desired rifling spin.

- Finish the rifling. Repeat passes through the bore with the rifling hook cutter box as needed.

-

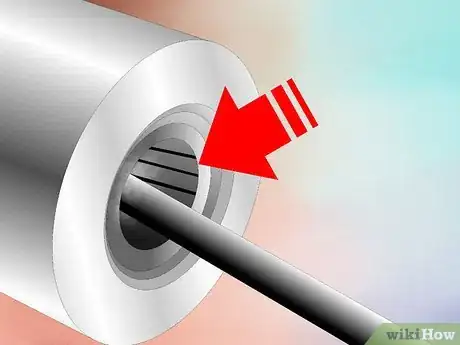

6Lap the barrel to fine polish the bore.

- Insert the barrel lapping rod into the bore until it is about 4 inches (101.6 mm) from 1 end of the bore. Pour molten lead into the end of the bore and allow it to harden.

- Push the lap out of the barrel. Push the lapping rod forward until the now solidified lead slug, called the lead lap, is exposed. Cover the lead lap with lapping paste, which is similar to valve grinding paste.

- Complete the lapping. Run the lead lap up and down the length of the barrel about 50 times, applying more lapping paste as necessary.

Community Q&A

-

QuestionWhat shape should the chamber be?

Community AnswerIt depends on the type and caliber of the weapon. The The Sporting Arms and Ammunition Manufacturers' Institute (SAAMI) has standardized dimensions for bullet casings and chambers to ensure safe interchangeability of rounds from one manufacturer to the next. For muzzleloading firearms, the diameter is typically the same as the barrel.

Community AnswerIt depends on the type and caliber of the weapon. The The Sporting Arms and Ammunition Manufacturers' Institute (SAAMI) has standardized dimensions for bullet casings and chambers to ensure safe interchangeability of rounds from one manufacturer to the next. For muzzleloading firearms, the diameter is typically the same as the barrel. -

QuestionHow would a Damascus twist barrel be forged?

Community AnswerForge a billet to the length that is needed. The barrel will need to be perfectly square. Then, twist the square billet. Make sure that it's 1-4 inches wider than it needs to be. Then, cool grind to your desired shape, heat treat, and etch.

Community AnswerForge a billet to the length that is needed. The barrel will need to be perfectly square. Then, twist the square billet. Make sure that it's 1-4 inches wider than it needs to be. Then, cool grind to your desired shape, heat treat, and etch. -

Question8.8 bolts OK for making a barrel? Their strength is 21 - 32 HRC.

Community AnswerThe Idahoan says yes, but admits he was trying to make a pistol barrel using simple tools, as shown by the roughness of the finished product.

Community AnswerThe Idahoan says yes, but admits he was trying to make a pistol barrel using simple tools, as shown by the roughness of the finished product.

Things You'll Need

- Steel rod

- Steel cutting and working tools

- Deep hole drill

- Barrel reaming drill

- Rifling hook cutter

- Barrel lapping rod

References

- ↑ http://www.firearmsid.com/Feature%20Articles/RifledBarrelManuf/BarrelManufacture.htm

- ↑ http://riflebarrels.com/the-making-of-a-rifle-barrel/

- ↑ http://riflebarrels.com/the-making-of-a-rifle-barrel/

- ↑ https://vortakt.com/firearms-industry/barrel-blanks-101/

- http://firearmsid.com/Feature%20Articles/RifledBarrelManuf/BarrelManufacture.htm

- http://www.lasc.us/RangingShotBarrelMakingFeature.htm