X

wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 11 people, some anonymous, worked to edit and improve it over time.

This article has been viewed 59,177 times.

Learn more...

Are you interested in repairing lead pipes that are over 100 years old? When contemplating the repair of a leaking joint in a bell and spigot cast iron soil pipe, sometimes it becomes necessary to repair or to replace the leaking joint in a bell for a variety of reasons; whether you are replacing the leaking joint or repairing it to reduce expenses, cast iron pipes are heavy and require an intensive amount of work to caulk the joints with oakum.

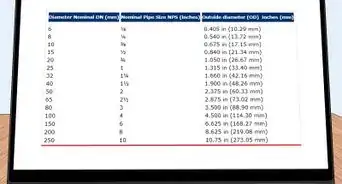

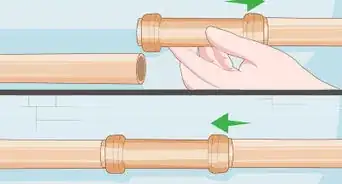

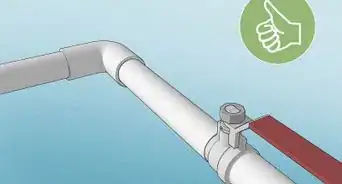

- Lead pipes have been modernized with what's called 'No-Hub' cast iron pipe and fittings.[1] The 'No-Hub' piping system lacks the flared ends into which the plain ends of pipe are caulked. All joints between pipe and fittings are made using rubber sleeves and stainless steel bands torqued to sixty inch/pounds. The bad section is removed, a new piece slid in, and new clamps are used to complete the repair.

Steps

-

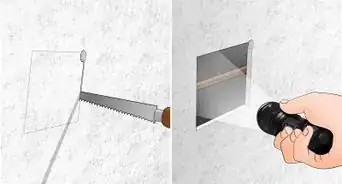

1Remove the lead and oakum in the leaking joint. This can take anywhere from a few minutes to several hours, depending upon the location of the joint, its size and the level of your commitment to the process. There are times when one simply MUST do a caulked joint, and times when the quick, cheap, and easy nature of PVC makes the choice a 'no-brainer'.[2]

-

2Remove ALL of the material from the joint. It's pretty much impossible to get a leak-free repair from a partial replacement of the original seal.Advertisement

-

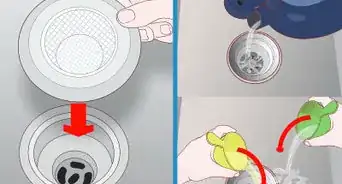

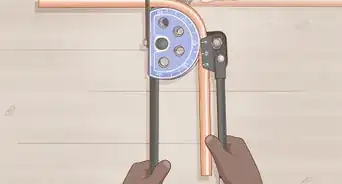

3Once the joint is properly prepared (clean and dry, with no residual 'stuff'), fill it with oakum (a tarry hemp fiber), which is packed into the space between bell and spigot using steel instruments called 'caulking irons.' Old screwdrivers make good improvised caulking irons.

- Pack each with several turns of oakum so as to make a relatively solid joint between the pipes. These layers are continually hammered into the joint, around and around, until there's only one inch of space between the top of the oakum and the rim of the hub.[3]

-

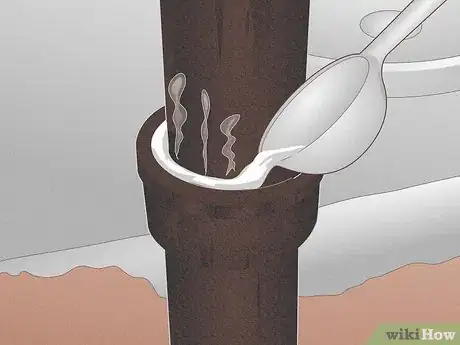

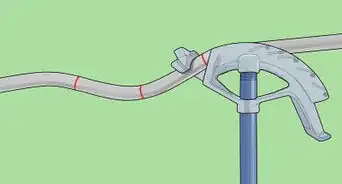

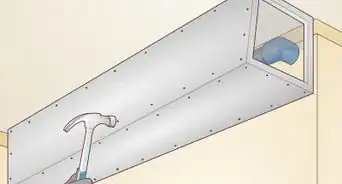

4Fill the last space. The remaining one-inch space will be filled with molten lead in one continuous pour, and the surface of the lead hammered around and around the circumference of the joint ensures a solid seal between the iron and the lead. Horizontal joints require the use of a joint runner, which is a non-combustible rope which is clamped around the top of the joint with a space at the top into which the molten lead is poured.

-

5Every joint must consist of one inch of lead, all poured at once. Oakum must be hammered so as to compress and seal the gap between pipes. Joint runners permit the pouring of vertical joints in horizontal pipes.

Advertisement

Community Q&A

-

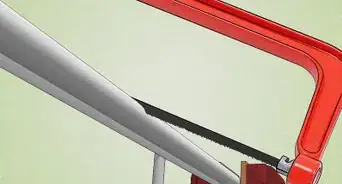

QuestionHow do I remove the bell on a cast iron pipe?

Community AnswerCut it off with a grinder or reciprocating saw for the cleanest result. Or you can rent a Chain Cutter made for the job, they're hit or miss on a clean edge, but the quickest overall.

Community AnswerCut it off with a grinder or reciprocating saw for the cleanest result. Or you can rent a Chain Cutter made for the job, they're hit or miss on a clean edge, but the quickest overall. -

QuestionWhat if the oakum has come loose and clogged the pipe?

Community AnswerGet a flame or torch in there to burn it off or cut it free. Otherwise, you have to redo the connection and pull it out with everything else after separating the pipes.

Community AnswerGet a flame or torch in there to burn it off or cut it free. Otherwise, you have to redo the connection and pull it out with everything else after separating the pipes.

Advertisement

Warnings

- Molten lead exceeds 800 °F (427 °C).⧼thumbs_response⧽

- There is a risk of lead poisoning. Melt lead with adequate ventilation.⧼thumbs_response⧽

Advertisement

References

About This Article

Advertisement