X

wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, volunteer authors worked to edit and improve it over time.

This article has been viewed 48,160 times.

Learn more...

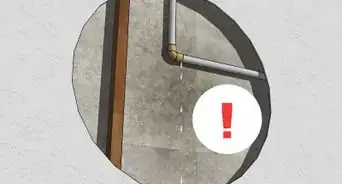

Mechanical seals are used in centrifugal pumps to keep water or any liquid from making contact with the delicate parts of the machine. They are situated on the shaft of the motor. Regular maintenance of these seals is needed to ensure there are no leaks. This article teaches you how to replace the mechanical seal. You will need to purchase a new seal to be able to follow these instructions.

Steps

-

1Turn off the power. If the centrifugal motor is in motion, turn it off. Shut off the main power supply. Ensure that there is no possibility of the machine starting up, once you get to work.

-

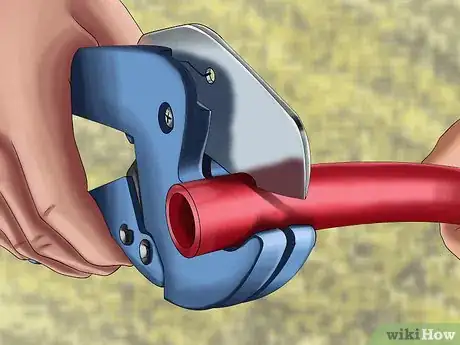

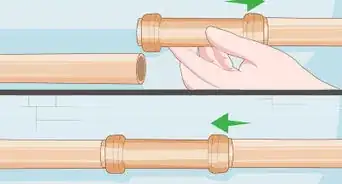

2Cut the plumbing. Cut the plumbing tubes connected to the centrifugal pump. You can use a saw to perform this action. Once disconnected, you are free to set the pump on a table or the floor, wherever you are comfortable.Advertisement

-

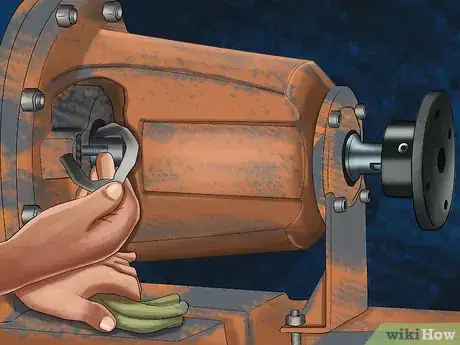

3Disconnect the pump. Using a wrench, unscrew the bolts holding the pump housing in place. Carefully disconnect and detach the pump located beyond the housing. Keep these bolts safe. You will need it later to reattach this setup.[1]

-

4Dismantle the centrifugal pump’s impeller. The seal is located on the shaft behind the impeller. To detach the shaft, first hold the shaft in place using a wrench. Then unscrew the impeller by rotating it.

-

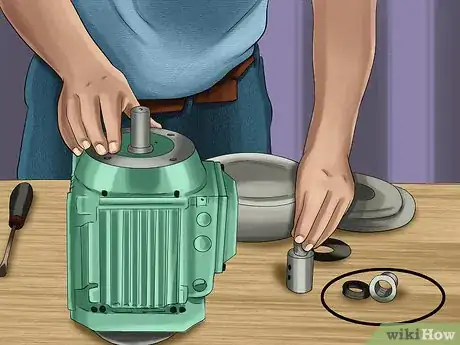

5Remove the seal. Part of the seal will be attached to the impeller, while the other part will be attached to the motor shaft. Slide the seal off from both these places.

-

6Replace the seal. Slide a mechanical seal along the shaft of the motor. Note that the front face of the shaft is extremely sensitive, even to the oils secreted by the fingers. Make sure that you don’t touch the face.[2]

-

7Screw on the impeller. With the help of a wrench, hold the motor shaft. Screw on the impeller.[3]

-

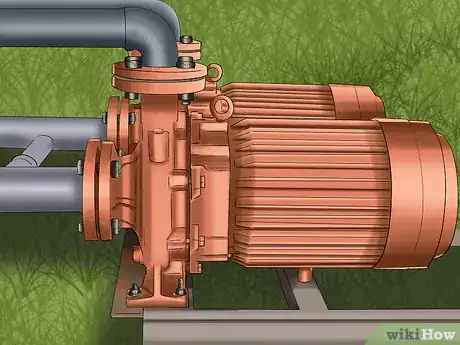

8Reconnect the pump. Using a wrench and the bolts from Step 3, reattach the pump and the motor.

-

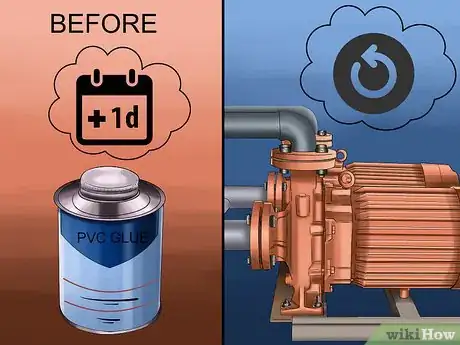

9Reconnect the centrifugal pump. Place the reconnected system back into the plumbing. Reconnect the plumbing tubes with the help of industrial strength PVC glue and primer.

-

10Restart the machine. After reattaching the plumbing to the centrifugal pump, the PVC glue and primer takes a minimum of one day to dry off completely. Start the machine after a day.

Advertisement

Community Q&A

-

QuestionWhat clearance should there be between the impeller and the backing plate?

Community AnswerLook on the pump shaft, you usually can see the mark where the set screw was previously. Use the same mark.

Community AnswerLook on the pump shaft, you usually can see the mark where the set screw was previously. Use the same mark. -

QuestionWhy is it important to ensure mechanical seals are correctly tensioned?

Community AnswerIf the tension is too tight, the new seal will not last as long due to more heat from increased friction. Too loose will result in the seal leaking prematurely.

Community AnswerIf the tension is too tight, the new seal will not last as long due to more heat from increased friction. Too loose will result in the seal leaking prematurely. -

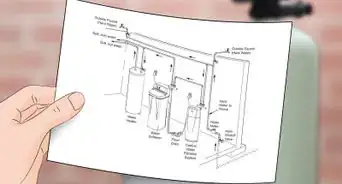

QuestionWhere can I find a step by step diagram for replacing a seal?

Community AnswerIf you are referring to a mechanical seal, then I usually find that if you phone the pump manufacturers and ask nicely, they will usually send out some information to help. You can also search for Vulcan seals on the internet and ask for one of their seal books to be posted to you (they are free).

Community AnswerIf you are referring to a mechanical seal, then I usually find that if you phone the pump manufacturers and ask nicely, they will usually send out some information to help. You can also search for Vulcan seals on the internet and ask for one of their seal books to be posted to you (they are free).

Advertisement

Warnings

- Ensure that there is no power supply to the machine when dismantling it.⧼thumbs_response⧽

- Be sure to wear the right safety gear including industrial grade shoes, hard hats, protective gloves, safety glasses, etc.⧼thumbs_response⧽

Advertisement

References

About This Article

Advertisement