This article was co-authored by Jeff Baldwin. Jeff Baldwin is a Residential Painter and the Owner of Baldwin Custom Painting. With two decades of painting experience, Jeff specializes in high-end residential and small commercial painting projects. Dedicated to quality craftsmanship, Jeff and Baldwin Custom Painting provide bonded/insured, licensed, and lead-safe certified services in residential painting, light commercial painting, and wood refinishing.

There are 12 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 125,131 times.

If you have a piece of wood furniture that needs a finish treatment, it's a great idea to highlight its beautiful wood grain instead of painting over it. In order to do this, you will need to seal the wood so that the surface is both showcased and protected. To seal wood properly first prepare the surface by sanding it smooth and, if you like, staining it a color. Then you can apply a sealant, but there are many to choose from. The three most common sealants are polyurethane, shellac, and lacquer, and each requires a different method of application.

Steps

Smoothing and Staining the Surface

-

1Sand the wood until it is very smooth. Sand the entire surface with a hand sander or an electric sander to get rid of rough areas and imperfections.[1] If your wood is pretty rough to start with, begin sanding with a rough sandpaper with a grit of 100 or 120. Progress from rougher grit to finer grit sandpapers, which allows you to reduce major irregularities before achieving a fine finish. To get a very smooth surface you should end with 400 grit sandpaper.[2]

- Even if your wood already feels pretty smooth, take the time to run 400-grit sandpaper over it before sealing it. This will ensure that the surface is completely smooth once the sealant is applied.

- Sand with the grain, which means that you need to follow the lines of the wood grain straight back and forth. This will help you avoid leaving behind swirly marks on the surface.

Warning: Wear a dust mask while you are sanding to avoid inhaling wood particles.

-

2Remove any sawdust from the surface with a dry rag or a tac cloth. Wipe the entire surface several times. This will help you avoid getting wood particles stuck in your sealant, which will create an imperfect surface.[3]

- A tac cloth is a special sticky cloth that is specially made to remove the dust from the surface of wood after sanding. Tac cloth will remove even fine particles that resist removal from a cloth.

- Avoid using water on unsealed wood, because it can alter the wood's grain and create roughness.

Advertisement -

3Stain the wood to change the color or to highlight the grain, if desired. Apply the stain before you apply your sealant so that it is able to soak into the surface. There are a variety of colors and types of stains available but most are applied with rags. First you will wipe your stain on the wood and then let it set for a specific amount of time, which is stated on the stain packaging. Then you will wipe off the excess with a clean, dry rag.[4]

- The container of your stain will tell you how long you need to wait after applying stain to apply a sealer.

- Wood stains are available at all hardware and home improvement stores.

-

4Use a stain and sealant combo to complete your project quickly. These products allow you to apply colorant and create a water-resistant surface at the same time. They are a quick-finish option if you have a large surface and not a lot of time to seal it.[5]

- For example, many people use this type of combo product with sealing a deck, due to the large surface area that needs to be treated.

- They are available at all hardware and home improvement stores.

- These products can typically be applied with a brush or a roller.

Sealing With Polyurethane

-

1Choose a polyurethane product that works for your project. There are different types of polyurethane, including oil-based, water-based, and other synthetic mixes. Each type has different characteristics, so think about where your wood is located and how it will be treated in the future to pick the right product.[6]

- For example, oil-based poly will stand up better to the elements outdoors but it takes much longer to dry and cure than water-based products. Water-based poly won't last quite as long outdoors but can be washed out of tools easily.

- When picking out a product, you also need to decide between a glossy and matte finished surface.

Tip: Polyurethane is a great product for waterproofing wood. It is easy to apply, lasts for a long time, and gives a beautiful finish. However, it will create a glossy or matte sheen finish, changing the look of the wood.

-

2Apply the polyurethane onto the wood with a brush or rag. Place the wood on a surface that can get covered in polyurethane. Either brush the polyurethane onto the surface of the wood or soak a clean rag with polyurethane and then smooth it around the face of the wood.[7]

- Polyurethane is self-leveling because it is thin enough to spread out on its own. This means that you should not have to worry too much about achieving an even coat.

- Make sure to use extra polyurethane for the end grain because this is the most absorbent part of the wood. The end grain is the exposed, cut part of wood on the end of the piece.

-

3Cover the entire surface with a smooth coat. Use long strokes with a clean brush or rag to spread out the polyurethane. Work from one side to the other, trying to keep the distribution of polyurethane on the surface of the wood equal and smooth.

- A rag with wipe-on polyurethane is the easiest method.

- Wear gloves during this entire procedure to avoid staining your hands.

-

4Sand between coats of polyurethane. Use fine 400 grit sandpaper to rub down the entire surface to eliminate imperfections. You don't need to push hard but be sure to lightly sand the entire surface.[8]

- After sanding, wipe down the surface with a rag in order to remove any dust you have created.

-

5Apply multiple coats of polyurethane to achieve your desired finish. Apply several coats of polyurethane to the surface of the wood, waiting for each coat to dry completely in between applications. Sand between coats to smooth out any uneven areas.

- Keep an eye out for any polyurethane drips, and smooth them out with your brush or rag to avoid a bumpy finish.

- Drying time varies, so make sure you read your polyurethane's instructions and keep an eye on the ambient temperature and humidity as well.

Using Shellac to Seal Wood

-

1Use shellac if you are sealing indoor wood that won't get wet. Shellac is a wood sealer that works well for indoor furniture.[9] While it's not waterproof, it does create a beautiful finish that protects your wood from drying out. If you have a piece of indoor furniture that you want to finish or refinish, shellac is a great choice.

- Shellac comes in a wide variety of colors, so it can be used to color and seal your wood at the same time.

-

2Get a clean sponge, brush, or rag to use to apply the shellac. Purchase one of these from your local big box, home improvement, or hardware store. It can be hard to clean and it usually thrown away after use, so don't buy an expensive tool to apply the shellac.[10]

- Use a sponge or rag if you need to cover a large surface.

- Use a brush if you need to get the shellac into tight corners and detailed areas.

-

3Apply the shellac in straight lines across the surface. Get your sponge, rag, or brush as saturated with shellac as possible before beginning your application. Wipe or brush is on and maintain a wet edge as you apply each band, so that the edge of each line is smoothed out by the next.[11]

- Start at one end of the wood face and work across quickly, making sure that the shellac doesn't dry as you apply the bands. Work quickly across each face of the wood, one band at a time.

- Shellac can be a challenging sealant to apply because you need to keep each band wet as you work on the next one.

-

4Don't touch the shellac while it's drying. In contrast to polyurethane, you should not interfere with the shellac's drying process or manipulate it in any way. Do not use steel wool and do not sand the shellac in between band applications.[12]

Tip: You can actually apply polyurethane or lacquer over shellac if you don't like the shellac and want to try a different finish.

Putting Lacquer on Wood

-

1Pick lacquer only if you have experience applying sealants. Lacquer is a very durable finish that is applied with a spray gun. It is a very high performance finish, drying quickly to a hard, with a durable finish. It is not easy to apply as an amateur, and is not forgiving of mistakes made during application.[16]

- A spray gun can be purchased for $50-$100, and is necessary if you plan to use lacquer.

-

2Take safety precautions while you apply lacquer. Maintain a ventilated area and don't spray lacquer near any sparks. Make sure to take the proper safety precautions when spraying lacquer.[17]

- Lacquer is highly toxic when inhaled, so make sure to maintain a well-ventilated area and wear a respirator.

Warning: If you are using a fan for ventilation, make sure it doesn't spark.

-

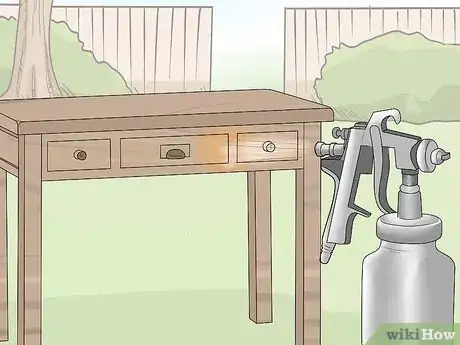

3Apply your lacquer in thin coats. Lacquer should only be applied in very thin coats with your spray gun. Pull the trigger as you get close to the piece, move the gun over the surface, overlapping the previous spray path by about 50%, and release the trigger just after moving beyond the edge. Move the spray gun back and forth over the surface quickly until the entire surface is coated.[18]

- Keep the gun moving so that you never allow a buildup of lacquer in one specific spot on the wood. This will help you avoid drips and the "orange peel" effect.

-

4Apply 3-4 coats of lacquer total. Wait for the lacquer to dry completely before applying additional coats. Once the surface is dry, which can take around 30 minutes, apply the next coat in the same fashion, making sure that the gun keeps moving and coats the surface evenly.[19]

- Once you have several coats applied, the surface will be sealed and smooth to the touch.

Expert Q&A

-

QuestionWhat should I do to seal the wood?

Jeff BaldwinJeff Baldwin is a Residential Painter and the Owner of Baldwin Custom Painting. With two decades of painting experience, Jeff specializes in high-end residential and small commercial painting projects. Dedicated to quality craftsmanship, Jeff and Baldwin Custom Painting provide bonded/insured, licensed, and lead-safe certified services in residential painting, light commercial painting, and wood refinishing.

Jeff BaldwinJeff Baldwin is a Residential Painter and the Owner of Baldwin Custom Painting. With two decades of painting experience, Jeff specializes in high-end residential and small commercial painting projects. Dedicated to quality craftsmanship, Jeff and Baldwin Custom Painting provide bonded/insured, licensed, and lead-safe certified services in residential painting, light commercial painting, and wood refinishing.

Residential Painter The best way to seal wood when you intend to paint it would be to use a stain-blocking primer that bonds well.

The best way to seal wood when you intend to paint it would be to use a stain-blocking primer that bonds well. -

QuestionWhat is the advantage of using white pigmented shellac?

Jeff BaldwinJeff Baldwin is a Residential Painter and the Owner of Baldwin Custom Painting. With two decades of painting experience, Jeff specializes in high-end residential and small commercial painting projects. Dedicated to quality craftsmanship, Jeff and Baldwin Custom Painting provide bonded/insured, licensed, and lead-safe certified services in residential painting, light commercial painting, and wood refinishing.

Jeff BaldwinJeff Baldwin is a Residential Painter and the Owner of Baldwin Custom Painting. With two decades of painting experience, Jeff specializes in high-end residential and small commercial painting projects. Dedicated to quality craftsmanship, Jeff and Baldwin Custom Painting provide bonded/insured, licensed, and lead-safe certified services in residential painting, light commercial painting, and wood refinishing.

Residential Painter White pigmented shellac is the best because it stain-blocks, goes on smooth, dries fast, sands easily, and locks in odors.

White pigmented shellac is the best because it stain-blocks, goes on smooth, dries fast, sands easily, and locks in odors. -

QuestionHow should I store the spray gun when not in use?

Community AnswerYou should store a spray gun in a plastic bag (everyday grocery bag), seal it with a rubber band at the base, and make sure it is kept in room-temperature storage.

Community AnswerYou should store a spray gun in a plastic bag (everyday grocery bag), seal it with a rubber band at the base, and make sure it is kept in room-temperature storage.

Things You'll Need

Smoothing and Staining the Surface

- Sandpaper, a variety of grits

- Rag

- Tac cloth

- Stain, if desired

Sealing With Polyurethane

- Polyurethane

- Brush or rag

- Fine-grit sandpaper

Using Shellac to Seal Wood

- Shellac

- Sponge, rag, or brush

Putting Lacquer on Wood

- Lacquer

- Spray gun

- Latex or rubber gloves

- Respirator

References

- ↑ https://www.bobvila.com/articles/sanding-wood/

- ↑ https://www.bobvila.com/articles/2145-quick-tip-choosing-sandpaper/

- ↑ https://thecraftsmanblog.com/how-to-prep-wood-for-stain/

- ↑ https://thecraftsmanblog.com/how-to-prep-wood-for-stain/

- ↑ https://www.bobvila.com/articles/how-to-waterproof-wood/

- ↑ https://www.thisoldhouse.com/ideas/all-about-polyurethane

- ↑ https://www.familyhandyman.com/woodworking/staining-wood/how-to-apply-polyurethane/

- ↑ https://www.bobvila.com/articles/how-to-apply-polyurethane-sealer/

- ↑ Jeff Baldwin. Residential Painter. Expert Interview. 1 March 2021.

- ↑ https://www.bobvila.com/articles/how-to-shellac-wood/

- ↑ https://www.bobvila.com/articles/how-to-shellac-wood/

- ↑ https://www.bobvila.com/articles/how-to-shellac-wood/

- ↑ Jeff Baldwin. Residential Painter. Expert Interview. 1 March 2021.

- ↑ Jeff Baldwin. Residential Painter. Expert Interview. 1 March 2021.

- ↑ Jeff Baldwin. Residential Painter. Expert Interview. 1 March 2021.

- ↑ https://www.woodcraft.com/blog_entries/working-with-lacquer

- ↑ https://www.docgreenwoodturner.com/lacquer.html

- ↑ https://www.woodcraft.com/blog_entries/working-with-lacquer

- ↑ https://www.thesawguy.com/how-to-lacquer-wood/

About This Article

Sealing wood helps to protect it from the elements and give it a clean, shiny finish. Before you apply your sealant, you’ll need to sand the surface with high-grit paper until it’s smooth. If you want to change the color of your wood, apply a stain at this point. For a quick and easy option, apply a stain and sealant combo product. If you’re not staining your wood, apply your sealant instead. Use a polyurethane product for a versatile, water-proof option. Just remember to sand the surface between coats if you use polyurethane. For indoor furniture and wood that won’t get wet, use a shellac sealant. This will leave your wood shiniest. For more tips, including how to seal wood with lacquer, read on!