wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 14 people, some anonymous, worked to edit and improve it over time.

There are 8 references cited in this article, which can be found at the bottom of the page.

wikiHow marks an article as reader-approved once it receives enough positive feedback. This article received 15 testimonials and 90% of readers who voted found it helpful, earning it our reader-approved status.

This article has been viewed 605,327 times.

Learn more...

Because copper and zinc have gone up in price, many artisans who etch designs in metals have turned to etching steel. Although not as fine a metal as copper, steel is finer than zinc, and it is also more durable--particularly when used as a printing plate. Several kinds of steel can be etched with acid,[1] including both mild steel and stainless steel. Following are instructions on how to acid-etch steel.

Steps

Preparing the Steel for Etching

-

1Choose the type of steel you want to etch. You can etch stainless steel, mild steel, or high-carbon steel. Which type of steel you etch will determine the best acid or chemical to use to etch it with.

-

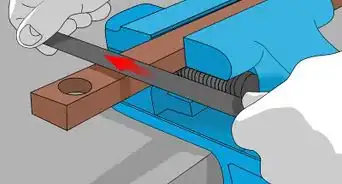

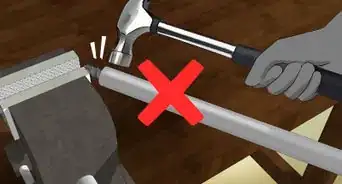

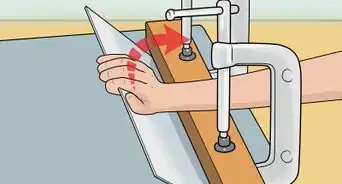

2Remove any burrs on the edges of the steel. File away any burrs on the side of the steel you plan to etch with acid. You can leave the burrs on the other side if you're etching a steel plate.Advertisement

-

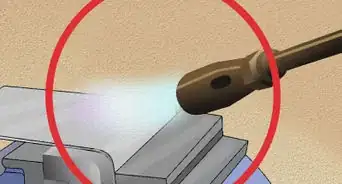

3Scrub the steel. Use a chlorine cleanser on an abrasive sponge, a wire brush, fine steel wool, wet number 600 emery paper, or corundum paper, scrubbing in a circular motion. You want to leave the surface just gritty enough to grip the resist material, but not so scratched that you end up etching extra lines that aren't part of your design.[2]

-

4Rinse the steel with water. The water should sheet off the steel surface.

-

5Clean the steel a second time with isopropyl alcohol.

Etching the Steel

-

1Choose the image you want to etch into the steel. You can either draw a freehand image or replicate an existing image onto the steel surface. Depending on which transfer method you use, you can have a fairly simple design or a complex one.

- If you plan to replicate an existing design, choose something in high-contrast black and white.

- If you plan to make and sell prints of your etching, choose an image in the public domain or get the permission of the copyright holder, if there is one.

-

2Transfer your design onto the steel surface. You can transfer the design in 1 of several ways, as described below. Be aware that however you transfer your design, it will print the reverse of the way you etch it into the steel. If you plan to use the etched steel plate solely as a decoration, not to print with, this won't matter to you.

- The oldest method for transferring designs is to coat the steel surface with a liquid varnish or wax-like substance (like beeswax), or even enamel paint or nail polish. This coating is called a ground. You then scratch your design into the ground using needles or wider-bladed cutting tools. (This is similar to woodcutting.) The ground will serve as a resist to keep the etching acid off the steel it covers.[3]

- Another method is to cover the steel surface with permanent markers in those places where you want the acid not to etch the steel and leave the surface exposed where you want to etch the steel. You may need to experiment with several brands and colors of permanent marker to determine which makes the best resists.

- A third method is to create an iron-on stencil by either photocopying an image onto transfer paper or printing it onto glossy photo paper with a laser printer. Place the paper onto the steel surface, image-side down, and using a clothes iron set to "high," iron with smooth, circular strokes for 2 to 5 minutes. (Press gently if using transfer paper; press hard if using photo paper.) You can then remove the paper. (Transfer paper will peel away on its own, but photo paper requires soaking in a tray of hot water to soften it for removal.) The transferred ink becomes the resist for the etching acid.

-

3Cover the steel's edges. You can tape over the edges or paint them. Either method keeps the acid from etching the edges.

-

4Choose the acid you want to etch the steel with. Possible acids include muriatic (hydrochloric) acid (HCL), nitric acid (HNO3), or sulfuric acid (H2SO4). Certain non-acids that form acid in water, such as ferric chloride (FeCl3) or copper sulfate (CuSO4), can also be used as etching chemicals.[4] How strong the acid is generally determines how fast the steel will be etched, or "bitten." You can obtain etching acids and chemicals through chemical supply stores or electronics supply shops.

- Ferric chloride is normally mixed with water in equal parts to form hydrochloric acid in solution. It's more commonly used to etch copper, but it also works well to etch stainless steel. It also works with a wider range of resist materials than pure acids do; however, it can pit the surface if not attended to properly.[5]

- Copper sulfate is better suited to etching mild steels than stainless steel. It is best mixed in a 1 to 1 ratio with sodium chloride (NaCl - common table salt) to keep the copper sulfate from coating the steel with a deposit of copper that will stop the etching process. The blue solution gradually fades as the etching progresses and turns colorless when it's finished.

- Nitric acid is commonly mixed in a ratio of 1 part nitric acid to 3 parts water. It can also be mixed with acetic acid (vinegar), in a 1 to 1 ratio, or with hydrochloric acid.

- Sulfuric acid should be used only in concentrations from 10 to 25 percent. Generally, dilute solutions are more effective than concentrated ones. Acids generally take longer to etch steel than do chemicals that form acids in water, however.

-

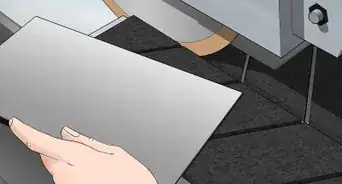

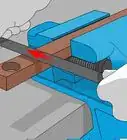

5Immerse the steel in a bath of the etching acid. Usually, you'll want to place the steel plate face-down in the solution so that the exposed metal flakes downward into the solution and away from the plate. This produces cleaner lines when etching the steel. If you put the plate in face-up, you can sweep away the flakes as they form with a light brush or feather; this will also remove bubbles that form. (The bubbles impede the etching process, but they can also create interesting designs if left alone.) Leave the steel plate in the etching acid until the lines are cut to the depth you want.

- Whether you put the steel plate in the etching acid face-up or face down, suspend it off the bottom of the container in some fashion. (This is particularly necessary when the plate is face down.)

- Tap the container holding the chemical bath periodically to keep the solution agitated.

-

6Remove and clean the steel plate. Wash the plate with water to remove the acid. If you used a particularly strong acid, you may also need to use baking soda to neutralize it. You then need to remove the resist; depending on the resist material, use one of the following methods:

- Use turpentine to remove paint or varnish grounds. (Use acetone if you used nail polish.)

- Use alcohol, methyl hydrate, or steel wool for wax-like grounds.

- Use running water for water-soluble inks and alcohol for inks insoluble in water.

Community Q&A

-

QuestionWhat thickness steel is best?

Community AnswerIt does not matter how thick the steel is, as the etch is only on the surface.

Community AnswerIt does not matter how thick the steel is, as the etch is only on the surface. -

QuestionHow can I acid etch into zinc or copper?

Community AnswerUse copper sulpate solution.

Community AnswerUse copper sulpate solution. -

QuestionIf I want to apply a finger print on stainless steel, would I cover the area with beeswax, touch it, and then put it in the acid bath?

Community AnswerNo. The purpose of the wax is to protect the area you do not want etched. The design you want etched into the metal has to be on the part that is not covered by the wax. Maybe if you dipped your finger in something, like oil or paint, then pressed that print to the metal, it might create enough resistance on the ridges of the fingerprint for it to work.

Community AnswerNo. The purpose of the wax is to protect the area you do not want etched. The design you want etched into the metal has to be on the part that is not covered by the wax. Maybe if you dipped your finger in something, like oil or paint, then pressed that print to the metal, it might create enough resistance on the ridges of the fingerprint for it to work.

Warnings

- Once the etching acid is too weak to use for etching steel, take it to a hazardous waste collection place. Do not pour it down the drain.⧼thumbs_response⧽

- Always work in a well-ventilated area and wear rubber gloves and safety goggles to protect your skin and eyes from the etching acid. It's also a good idea to have clean water nearby to flush your eyes or skin if you're accidentally exposed to the acid.⧼thumbs_response⧽

- When diluting acid, pour the acid into the water, not the water onto the acid. Adding water to concentrated acid causes it to heat up and splash out of the container. When you add the acid to water instead, the water carries the heat safely.[7]⧼thumbs_response⧽

Things You'll Need

- Piece of steel to be etched (plate or blade)

- Etching acid (hydrochloric, nitric, or sulfuric acid) or chemical (ferric chloride or copper sulfate)

- Rubber gloves

- Safety goggles

References

- ↑ https://www.tf.uni-kiel.de/matwis/amat/iss/kap_7/illustr/s7_1_2.html

- ↑ https://www.industrialmetalsupply.com/blog/tag/how-to-etch-metal/

- ↑ https://www.youtube.com/watch?v=BFYByXv9qkY

- ↑ https://vector.umd.edu/images/links/Handbook_of_Metal_Etchants.pdf

- ↑ https://www.polymetaal.nl/beguin/mape/edinburgh_etch.htm

- ↑ https://www.hometalk.com/17720539/diy-last-minute-father-s-day-gift-etching-stainless-steel?expand_all_questions=1

- ↑ https://sciencing.com/how-to-dilute-acid-13710252.html

- http://steampunkworkshop.com/electroetch.shtml

About This Article

To acid etch steel, start by drawing or printing your desired image onto the steel. Once you’ve finished your design, coat the steel with liquid varnish, enamel paint, or nail polish. When it’s dry, scratch your design into the coating using needles or wider-bladed cutting tools. After you’ve etched on your design, cover the steel’s edges with tape to stop the acid from etching the edges. Then, place the steel image-down in a bath of acid. When the lines are etched as deep as you want them, take the steel out of the acid and rinse it off with clean water. For more tips, including how to choose an acid to etch your steel with, read on!